Vision measuring method for spaced round geometrical parameters

A stereoscopic vision measurement and space technology, applied in the field of measurement, can solve the problems of not realizing circle radius measurement, etc., and achieve the effect of reducing measurement error, improving the degree of automation, and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

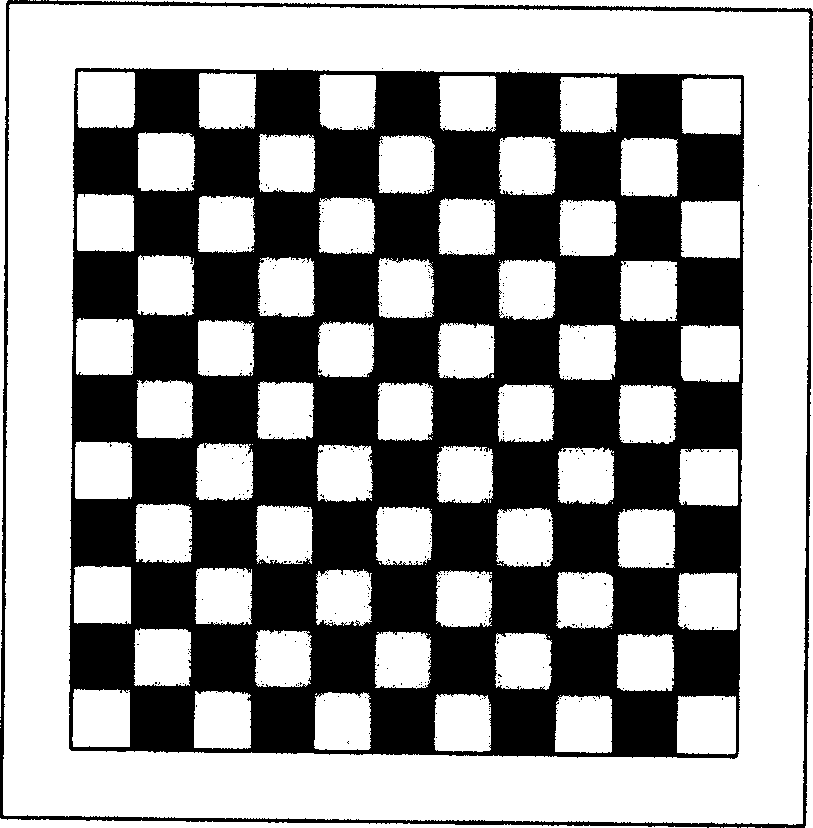

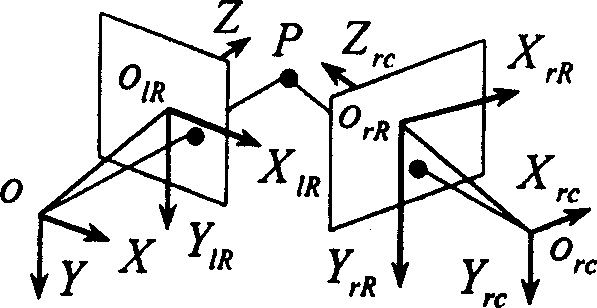

[0069] According to the steps described above, use two Mintong 368P CCD cameras and a 25mm Japan Seiko lens to form a binocular stereo vision sensor, and measure a circular hole with a diameter of D = 45.50mm. first use figure 1 The shown planar calibration target calibrates the CCD camera and the structured light vision sensor, and the distance between adjacent feature points in the planar target is 9±0.005mm. The obtained calibration parameters are:

[0070] Internal parameters of the left camera: A l = 4215.176 0 253.506 0 4203.932 383.968 0 0 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com