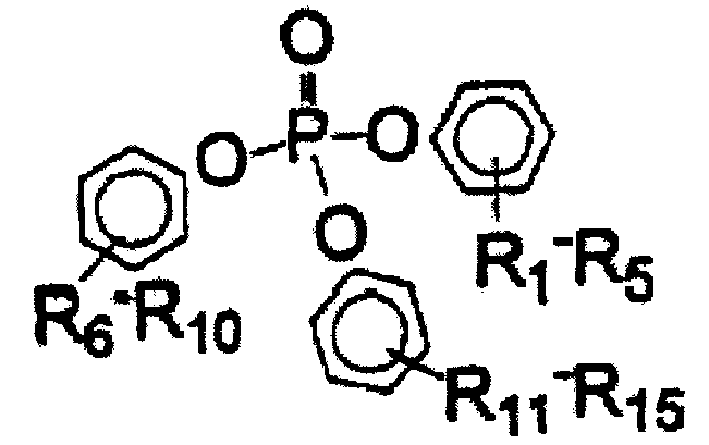

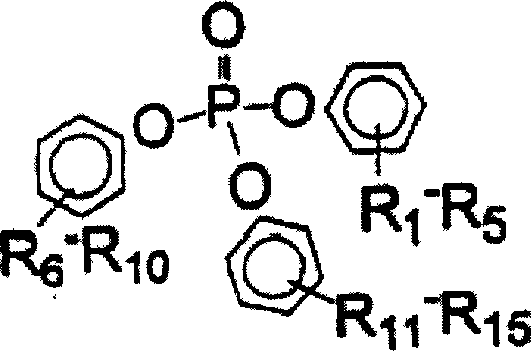

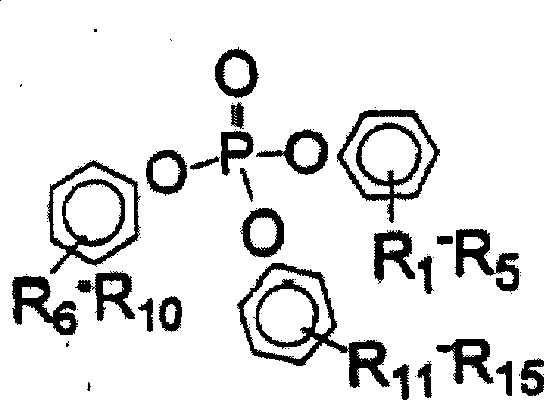

Higher alkylated triaryl phosphate ester flame retardants

A technology of triaryl phosphate and aryl phosphate, applied in the direction of phosphorus organic compounds, etc., can solve the problems of low foam physical properties, high non-halogen additives, and low efficiency of non-halogen flame retardants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 - Preparation of isopropylated triaryl phosphates

[0034] In this example, samples of isopropylated triaryl phosphates with different levels of alkylation were prepared for testing. The phosphate ester samples were produced by combining different ratios of propylene and phenol to produce alkylated phenol, followed by phosphorylation. The preparation is basically carried out according to the process given in Example 4 of US3,576,923. Phosphate ester samples are given in Table 1 below.

[0035] Phosphate

Embodiment 2

[0036] Example 2 - Preparation of Foam Samples

[0037] In this example, foam samples including the phosphate ester samples of Example 1 were prepared to evaluate flame retardant performance and its bloom characteristics.

[0038] Foam samples were prepared by mixing the polyol and phosphate ester samples together. Add the remaining formulation components, except the isocyanate, to the polyol / phosphate mixture and mix. Finally the isocyanate is added and stirred into the mixture.

[0039]The reaction mixture was poured into the box and allowed to swell well. The box containing the expanded foam was placed in a ventilated oven at 110° C. for 30 minutes to promote curing, and the foam samples were removed from their boxes and tested after storage at ambient conditions for at least 24 hours.

[0040] The foam sample formulations tested included 6, 7, 8 parts by weight phosphate samples from Example 1, and 4 and 5 parts by weight tris(dichloropropyl) phosphate, toluene diisocya...

Embodiment 3

[0048] Example 3 - Evaluation of Foam Samples

[0049] In this example, the foam samples from Example 2 were tested for flammability and aerosolization using standard procedures including FMVSS-302 for testing flammability and DIN 75102 for testing aerosolization.

[0050] The nebulization test included tris(dichloropropyl)phosphate (TDCP) as a control. In a foam using the same furnish with similar density and porosity, TDCP was observed to give an SE rating of 4php. DIN 75102 test results are given (unit weight). Less than 1mg of volatile substances is the current requirement.

[0051] The test results of flammability performance and fogging performance are given in Table 3.

[0052] Phosphate samples

[0053] SE * = Indicates that the flame self-extinguished before the 1.5 inch gauge mark during the flame test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com