Fixed high pressure water smoke fire-extinguishing system

A fire extinguishing system, fixed technology, applied in fire rescue, medical science, dental repair, etc., can solve the problems of poor safety, poor safety and low working pressure of gas fire extinguishing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

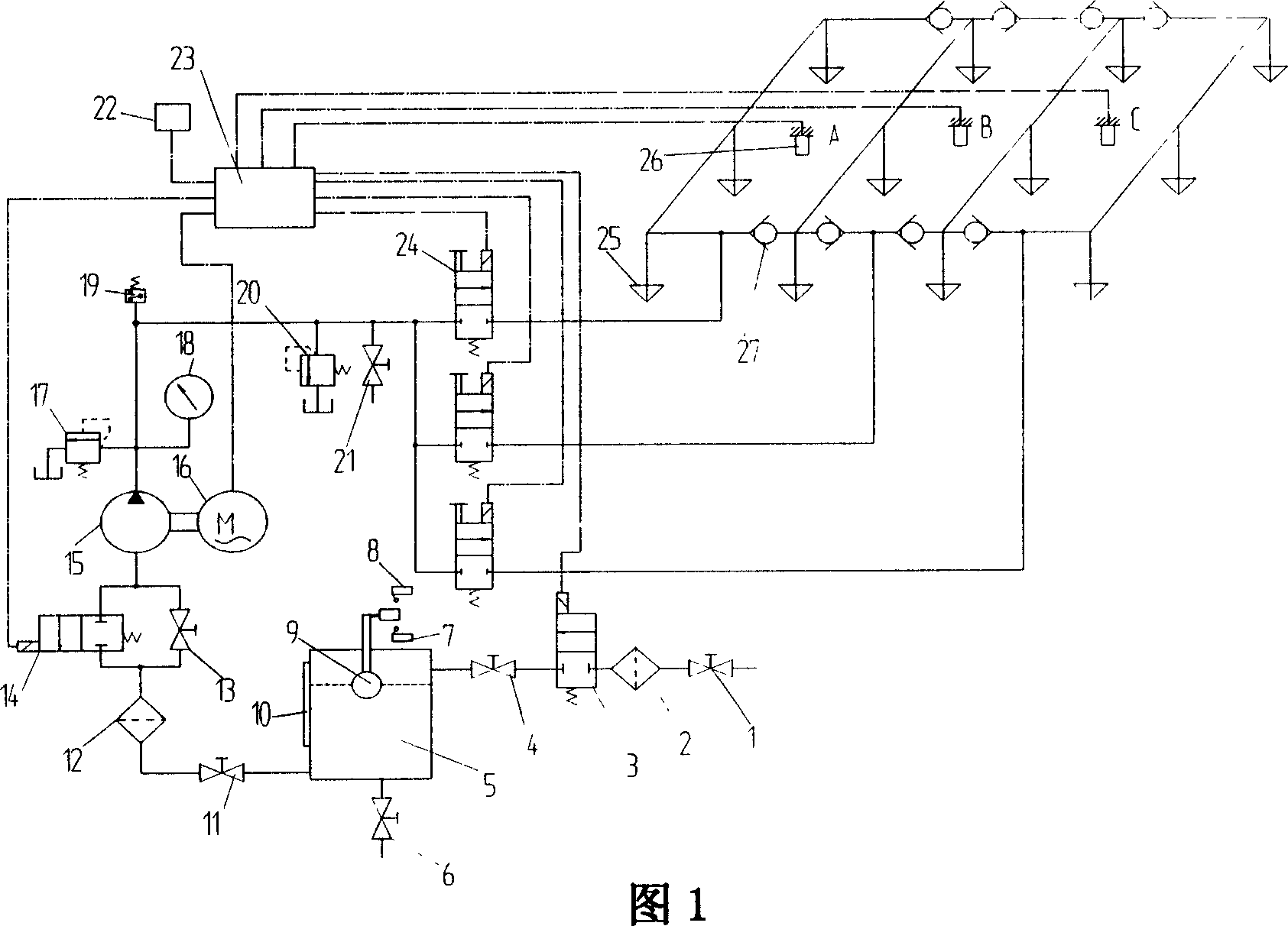

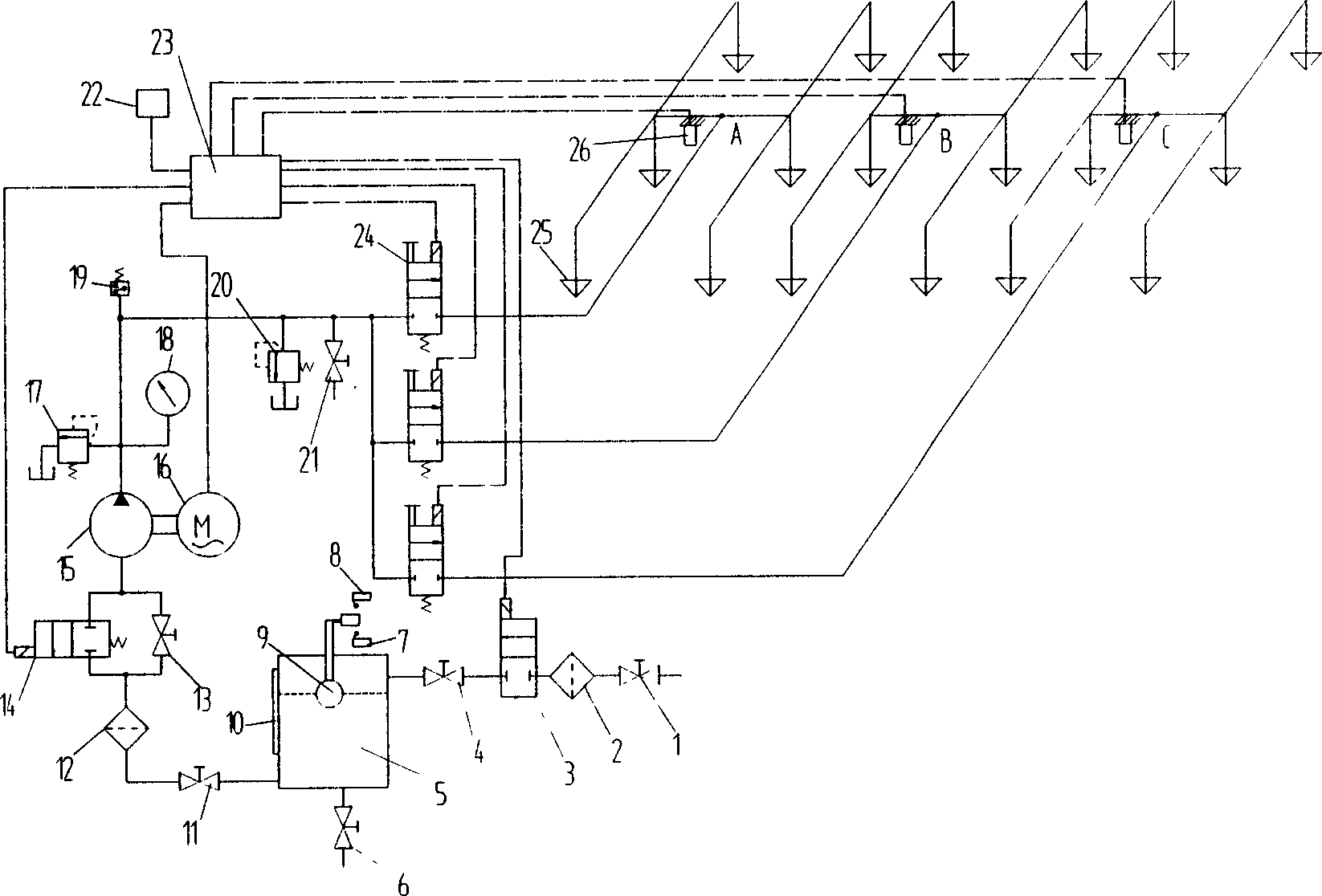

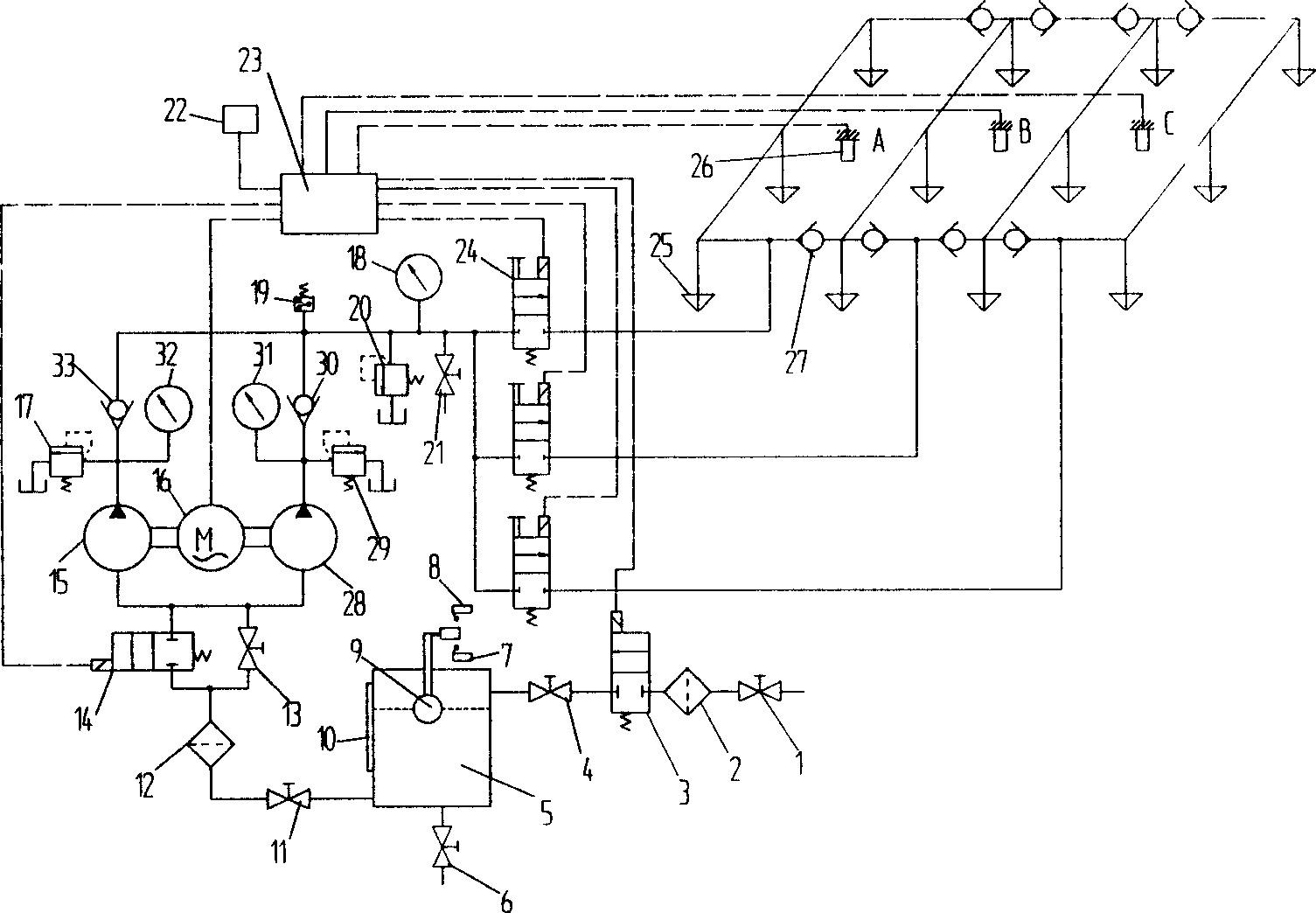

[0024] Figure 1 shows an embodiment of the present invention, including: manual switch valves 1, 4, 11, filter 2, electromagnetic switch valves 3, 14, water tank 5, drain valve 6, travel switches 7 and 8, buoyancy ball 9 , liquid level gauge 10, filter 12, manual on-off valve 13, sea and fresh water hydraulic pump 15, electric motor 16, overflow valve 17, 29, pressure gauge 18, pressure relay 19, safety valve 20, on-off valve for test / drainage 21. Alarm 22, controller 23, two-position two-way electromagnetic / manual reversing valve 24, high-pressure water mist nozzle 25, temperature / smoke detector 26, one-way valve group 27. When the area of the protected object is large, the protected object is divided into multiple areas, and each area is distributed with multiple high-pressure water mist nozzles, which are separated by one-way valve groups. Each area is equipped with a heat or (and) a smoke detector to monitor whether there is a fire in the area. When a fire breaks out in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com