Artistic porcelain with twistable glaze and its producing method

A production method and artistic technology, applied in the field of ceramic products, can solve problems such as single color, inability to meet the aesthetic needs of modern people, and lack of changes in the patterns of twisted body porcelain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

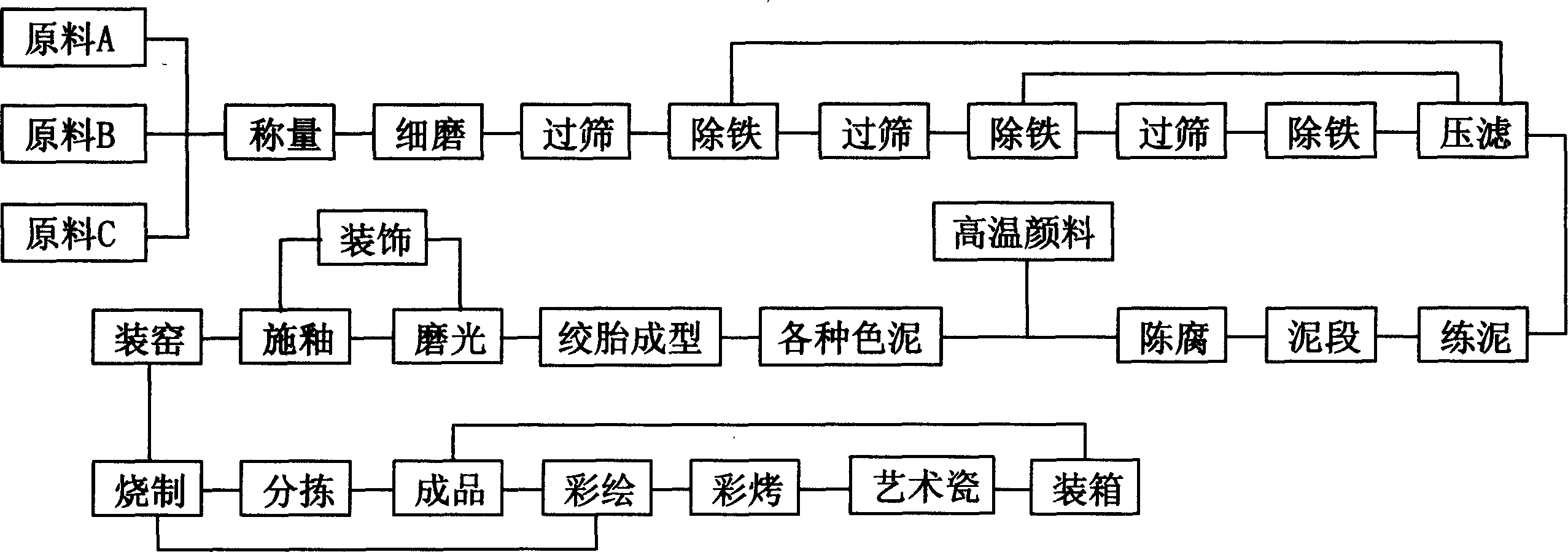

[0018] Embodiment 1, as shown in the accompanying drawings, is basically the same as the production method of daily-use porcelain, and the production method of twisted tire art porcelain is also composed of steps such as raw material processing, molding and firing,

[0019] a. In the raw material processing step, the raw materials used can refer to the composition of daily-use porcelain. According to the requirements of the formula, the raw materials are weighed and finely ground into a slurry. The slurry is sieved and iron-removed. The strength of the magnetic field is 10,000 gauss, and the sieve hole is 140. ~160 mesh, so that the fineness of the mud reaches 200 mesh sieve and all pass through, the balance of 250 mesh sieve is 0.1%, and the content of iron and titanium impurities in the raw material is Fe 2 o 3 ≤0.5%, TiO 2 ≤0.3%, in order to make the fineness and content of iron and titanium impurities meet the requirements, sieving and iron removal should be carried out a...

Embodiment 2

[0024] Embodiment 2: In the present embodiment, the deironing and sieving of the mud need to be alternately carried out four times, so that the fineness of the mud reaches 200 mesh sieves and passes through completely, and the sieve surplus of 250 mesh sieves is 0.3%, and the content of iron and titanium impurities in the raw material is Fe 2 o 3 ≤0.3%, TiO 2 ≤0.1%. The proportion of high-temperature pigments added is 0-5%. In the molding step, color muds of different colors are stacked multiple times, and then kneaded into a ball, and then the mud balls are made into mud by patting, beating, rolling, etc. Cake, or cut a certain thickness of mud cake from the mud cake, and finally according to the texture changes displayed on the surface of the mud cake or the cut surface, use the method of digging and inlaying to make a flat carcass with a certain color and the artistic conception and image of Chinese painting. Then the carcass is dried, thinned, smoothed and glazed with a...

Embodiment 3

[0027] Embodiment 3: In the present embodiment, the deironing and sieving of mud need alternately carry out four times, make the fineness of mud reach 200 mesh sieves and pass through completely, 250 mesh sieve surplus 0.3%, iron-titanium impurity content in the raw material is Fe 2 o 3 ≤0.5%, TiO 2 ≤0.3%. The firing temperature is 1350°C, and the heating time is 8.5 hours. The other steps are basically the same as in Example 2, but after making the plane carcass with various shapes, the mold is used to roll the plane carcass into a cylinder shape, press it into a disc shape or make a sphere, etc., or use Using methods such as rolling, splicing, inlaying, digging, dry splicing, wet splicing, transfer, etc., patterns such as landscapes, flowers and birds, or figures are transplanted onto various types of utensils.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com