Car seat slideway roller assembly machine

An assembly machine and roller technology, which is applied in the field of automatic assembly of front and rear rollers of car slideways, can solve problems such as high labor intensity, low work efficiency, and dependence on assembly quality, so as to reduce labor intensity and improve product quality and work efficiency, to ensure the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

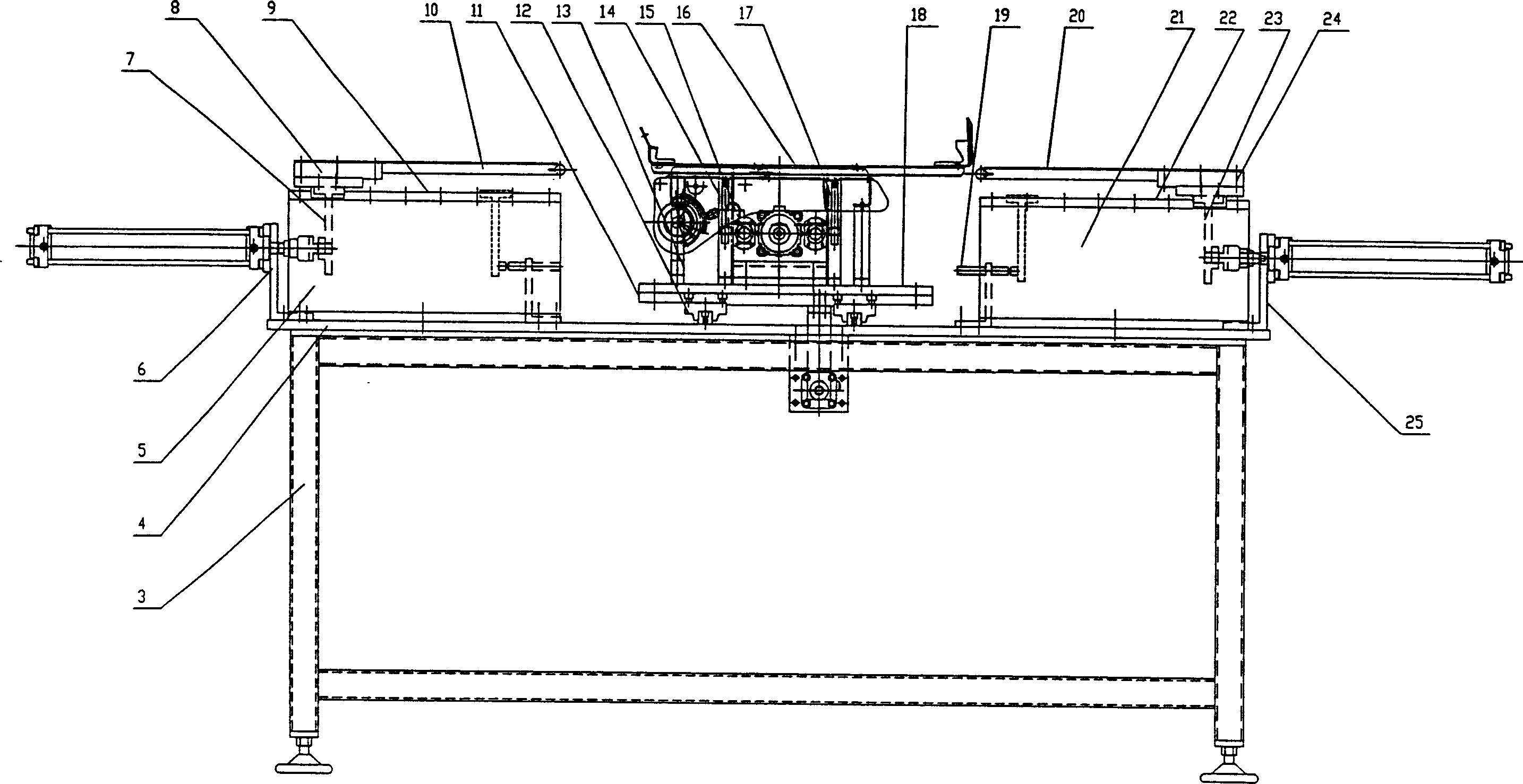

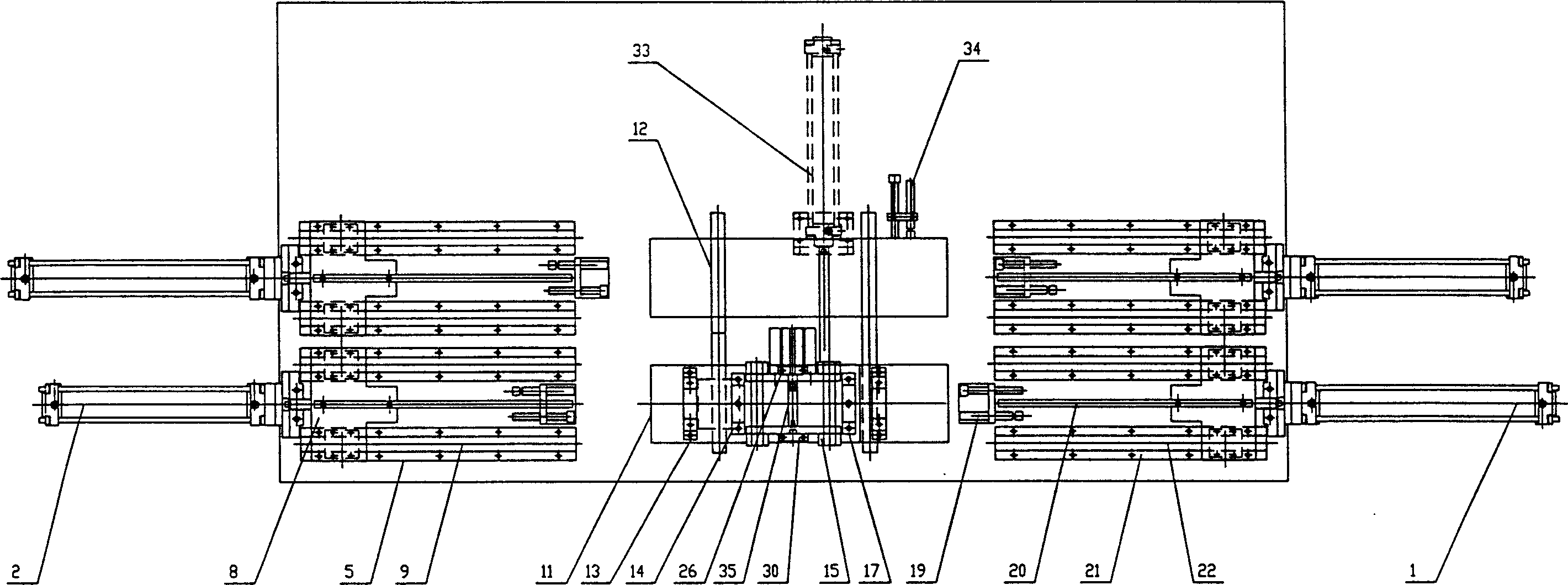

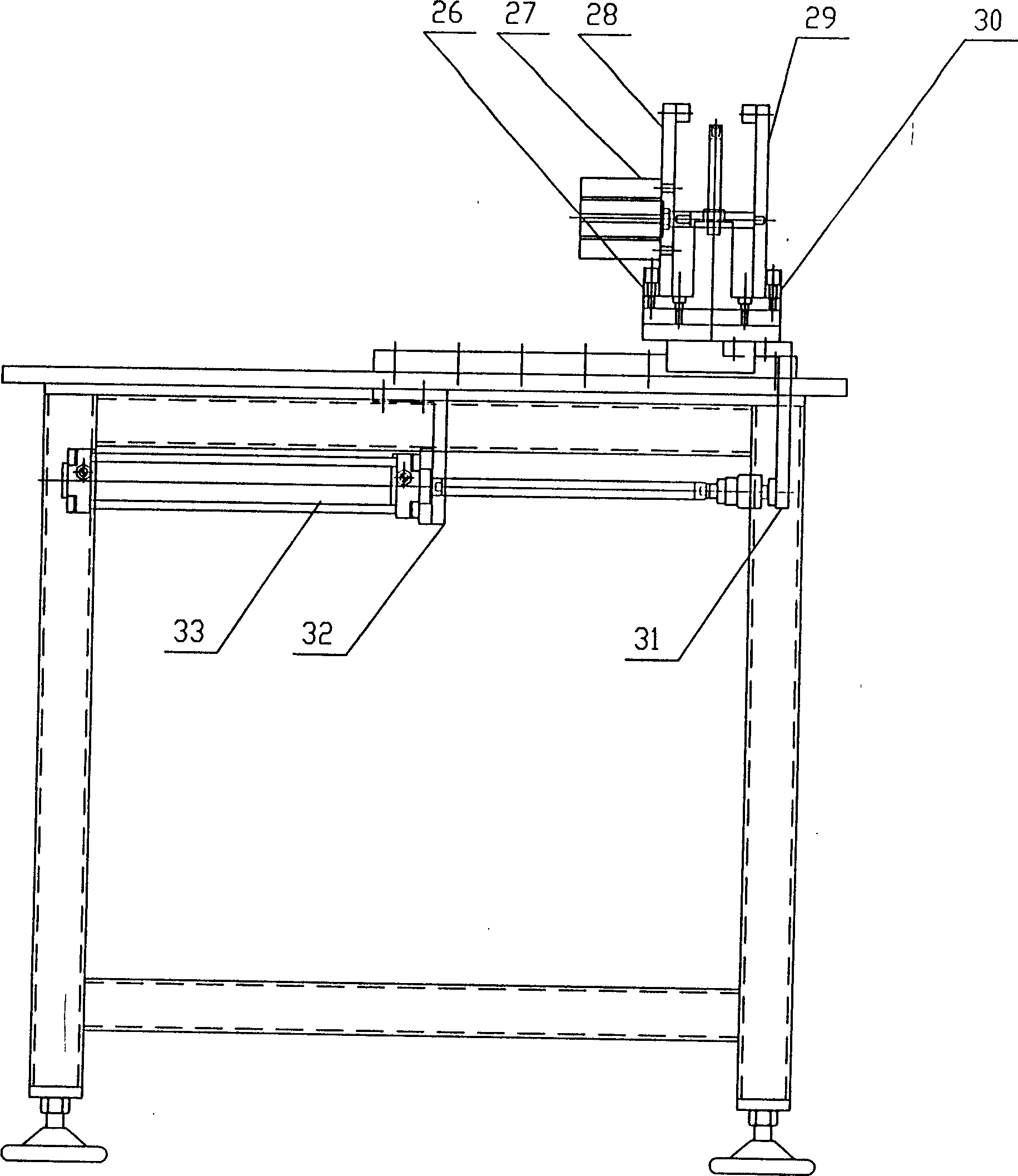

[0017] A preferred embodiment of the present invention is: see figure 1 , figure 2 with image 3 , The car seat slide roller assembly machine includes a frame 3 and a panel 4 fixedly connected to the frame 3. A workbench translation device is placed in the center of the panel 4; the workbench translation device passes on the mobile platform 11 Install a workpiece positioning and clamping device with bolts; on the front part of the panel 4, install a seat slide left roller assembly device, and on the rear of the panel 4, install a seat slide right roller assembly Device. The structure of the workbench translation device is as follows: there are two parallel support rails 12 fixedly connected to the panel 4 in the front and rear directions, a mobile platform 11 is slidably matched with the support rail 12 through its lower fixed sliding block; an air cylinder 33 passes through the cylinder mounting seat 32 It is fixedly connected under the panel 4, and the piston rod of the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com