Arch-type bridge pre-tensioned construction

A prestressed structure and prestressed technology, applied in the direction of arch bridges, bridges, bridge forms, etc., can solve the problems of difficult construction, damage to old structures, and aggravated structural dangers, etc., and achieve the effect of low construction difficulty and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

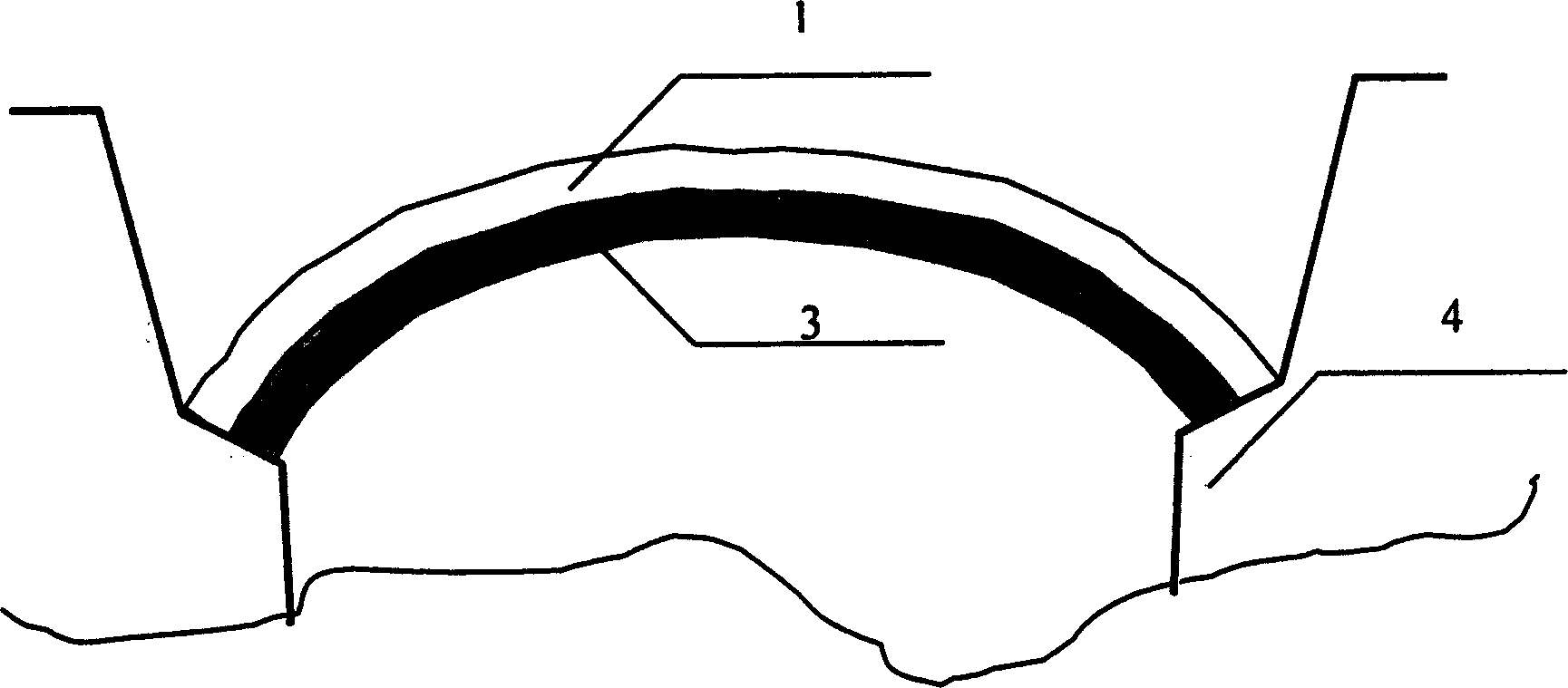

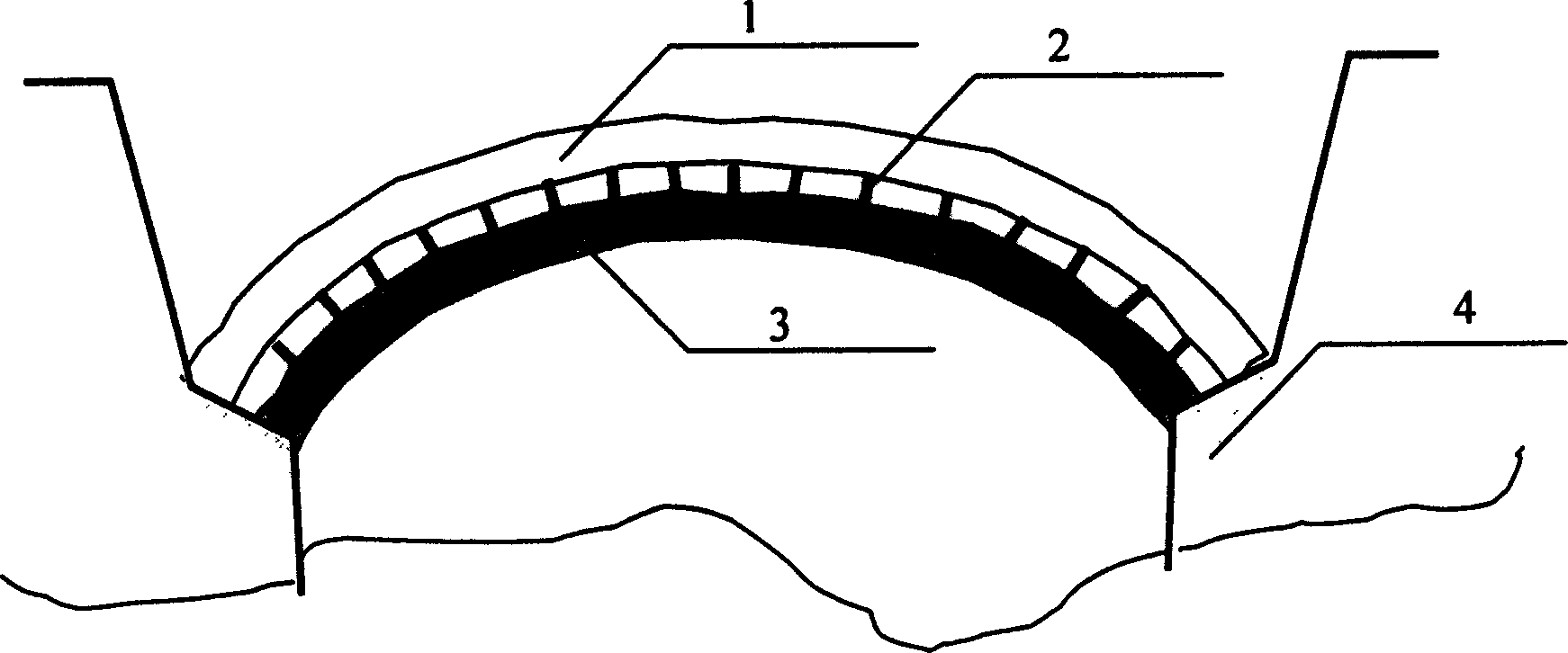

[0014] Such as figure 2 As shown, the present invention adds a new arch rib (3) below the old arch rib (1) of the arch bridge, and there is a gap of a certain size between the new and old arch ribs in the vertical direction, and a certain amount of prestressed loading is placed in the gap. device (2), operate the prestressing loader (2), rely on the old arch rib (1) to vertically load the new arch rib (3), and at the same time, the new arch rib (3) supports the old arch rib (1), so as to achieve the The function of lightening and reinforcing the old arch rib (1).

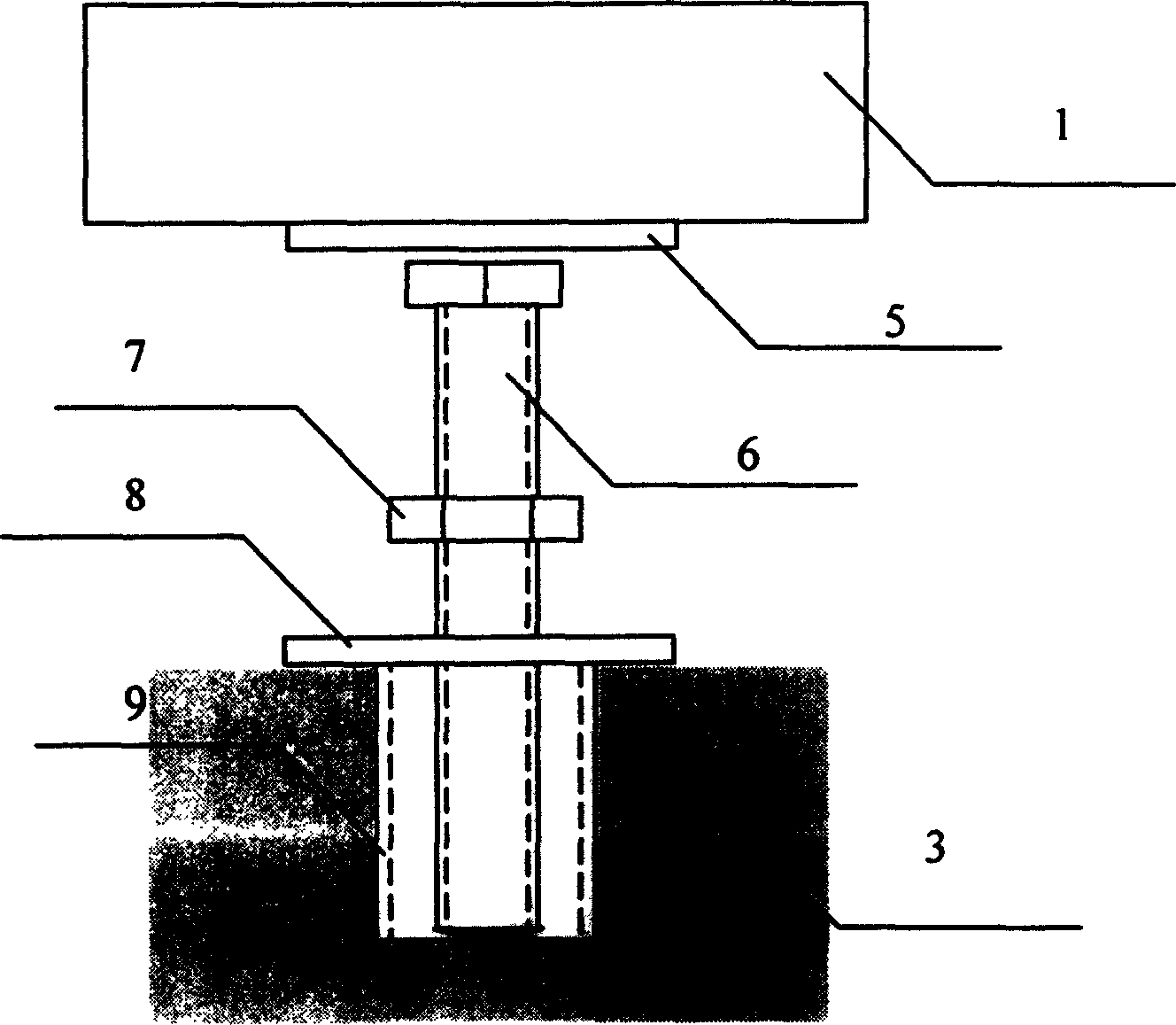

[0015] Such as image 3 As shown, the lower end of the screw rod (6) on the prestress loader (2) is inserted in the steel pipe (9) fixedly connected with the new arch rib (3), and the nut (7) on the rotary prestress loader (2) , so that the screw rod (6) is elongated, tops the backing plate (5), and the nut (7) presses down the backing plate (8), that is, the old arch rib is supported by the new arch rib (3) thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com