Auto-collimation interference measurement system for three dimensional angular distortion of object

A technology of interferometry and self-collimation, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems that the background technology cannot measure three-dimensional angle deformation, etc., and achieve the effects of improved precision, simple structure of the optical system, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

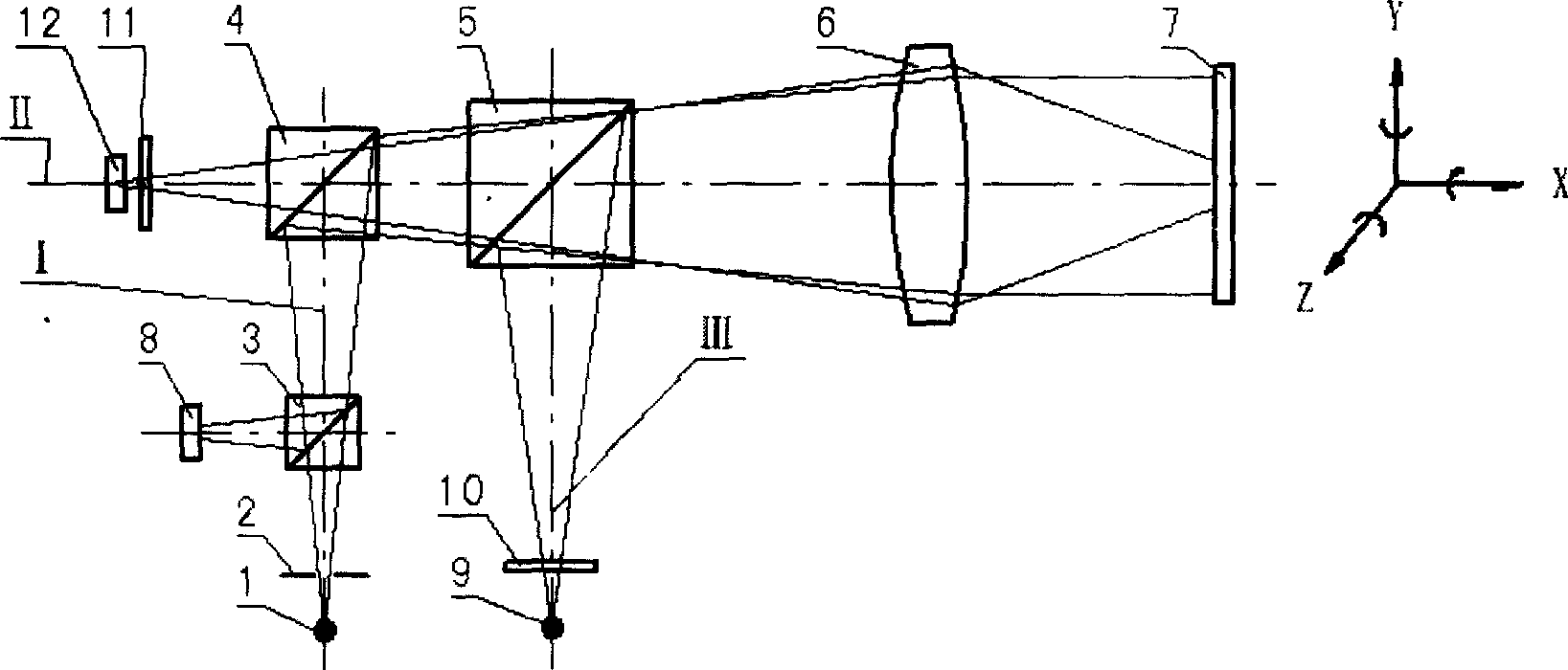

[0013] The invention presses figure 2 The schematic diagram shown is implemented. The first light source 1, the diaphragm 2, the first dichroic prism 3, the second dichroic prism 4, the third dichroic prism 5, the objective lens group 6, the reflecting mirror 7, and the CCD detector 8 form a main optical path; by the second light source 9 , Grating 10, third beam splitting prism 5, objective lens group 6, reflecting mirror 7, second beam splitting prism 4, grating 11 and CCD detector 12 form another main optical path; second beam splitting prism 4, third beam splitting prism 5, objective lens Group 6, grating mirror 7 is the common optical path part of the two main optical paths.

[0014] The first light source 1 can be an infrared light source; the diaphragm 2 can be a small aperture diaphragm; the first dichroic prism 3, the second dichroic prism 4, the third dichroic prism 5, and the reflecting mirror 7 can be made of K9 glass, which are made of two Three prisms are glued toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com