Micro mirror detecting method and device

A detection method and detection device technology, which are applied to measurement devices, optical devices, laser parts, etc., can solve problems such as consumption, huge time and manpower, and achieve the effect of improving product qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

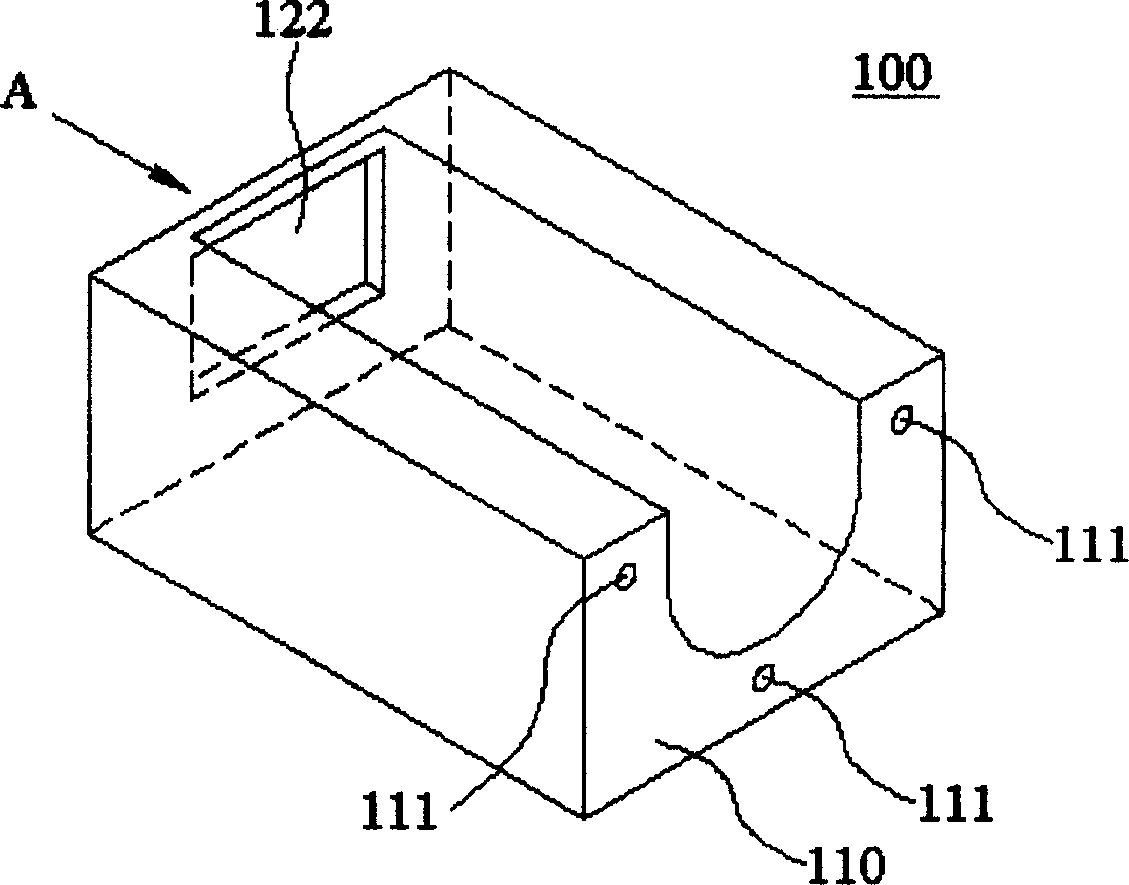

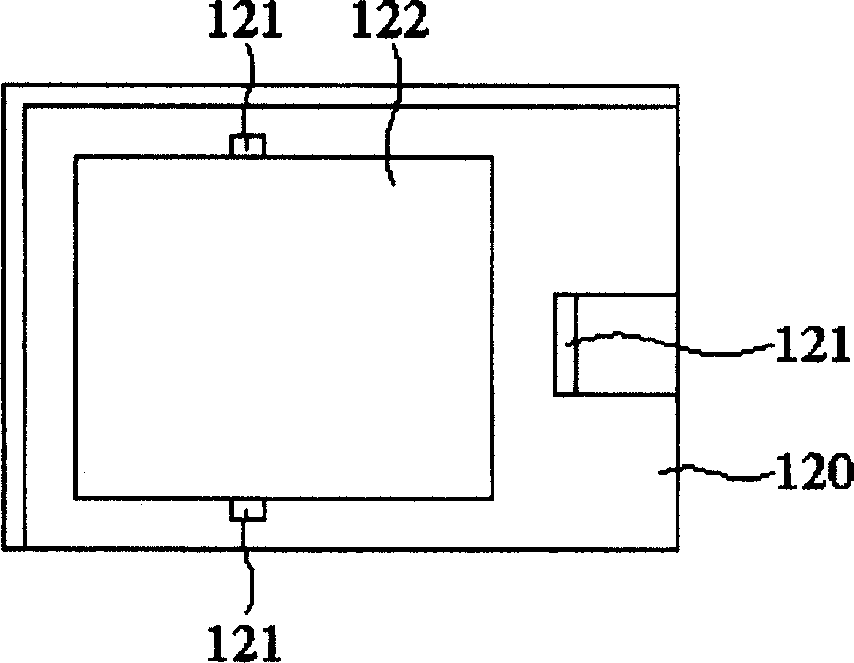

[0014] First, let’s explain the structural reference of the seat Figure 1a , the seat 100 includes a lens supporting surface 110 and a lens supporting point 111 . refer to Figure 1b , which shows the side view of the holder 100 in direction A, the holder 100 also includes a micromirror bearing surface 120 , and the micromirror bearing surface 120 has a micromirror bearing point 121 and an opening 122 . The micromirror assembly is arranged on the micromirror supporting surface 120 by the micromirror supporting point 121 . What the present invention needs to detect is whether the micromirror assembly is excessively tilted when it is installed on the micromirror bearing surface 120 .

[0015] The structure of the micromirror detection device of the present invention will be described below first, and then the micromirror detection method using the micromirror detection device will be described.

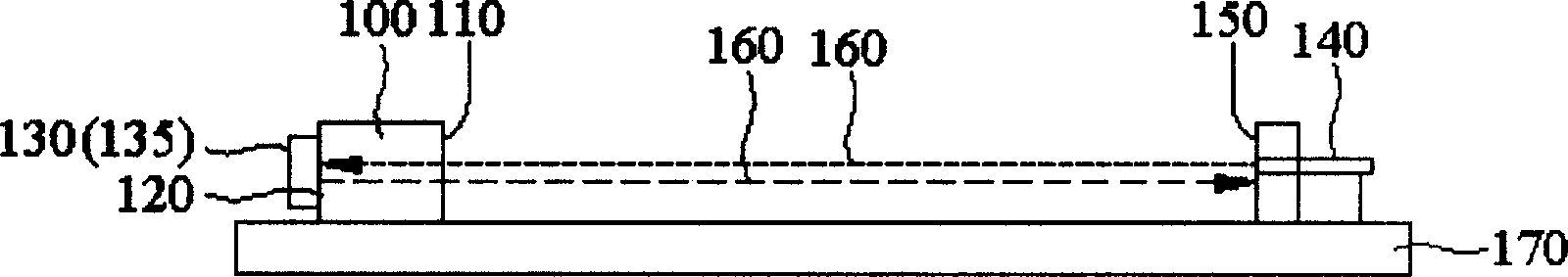

[0016] refer to Figure 2a , the micromirror inspection device of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com