Metal pliable hose

A flexible and flexible hose technology, applied in the direction of hoses, hose connecting devices, pipes, etc., can solve the problems of reducing corrosion resistance, high cost, and high cost of welding equipment, increasing friction and ensuring tightness , the effect of reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The metal flexible hose of the present invention will be described in detail below in conjunction with examples.

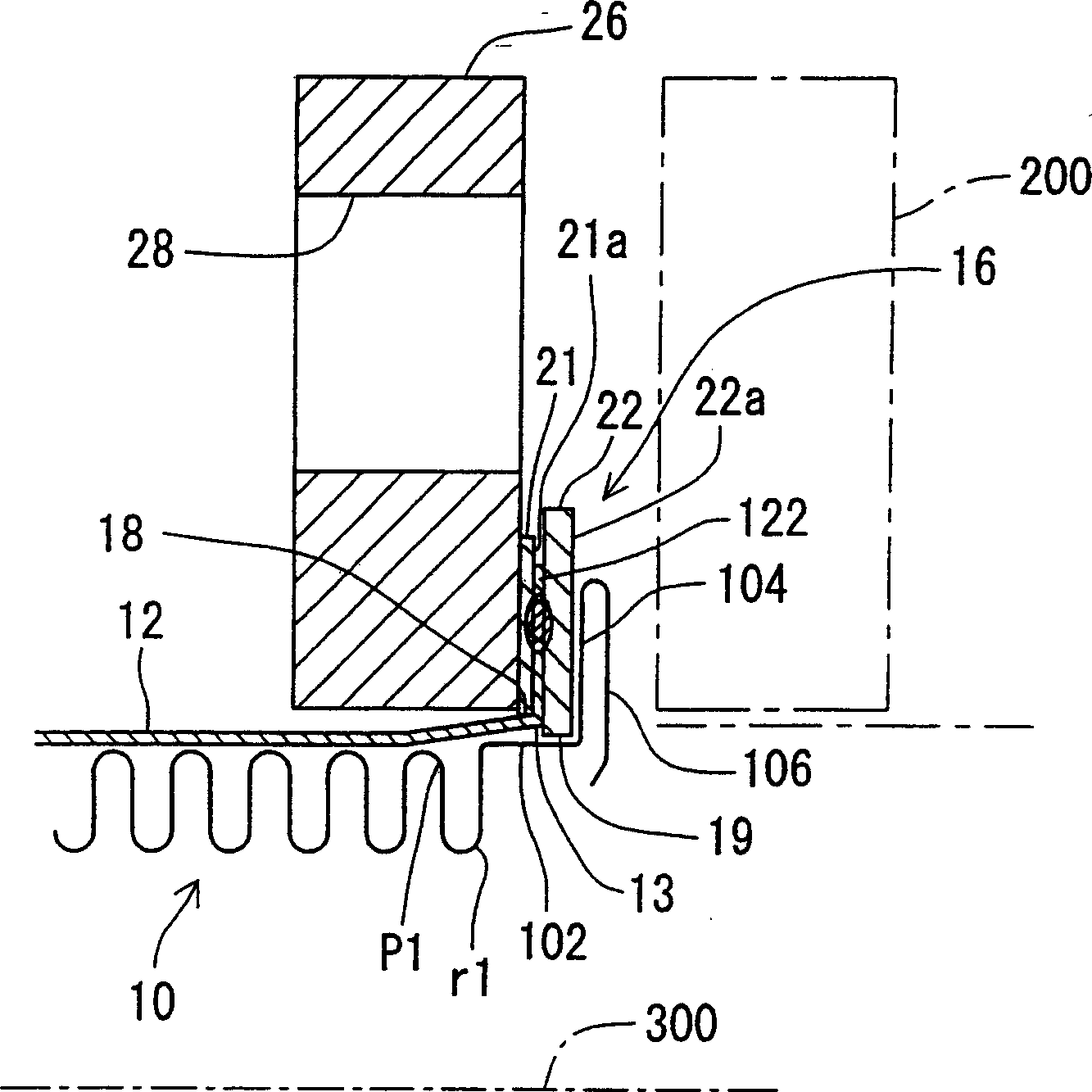

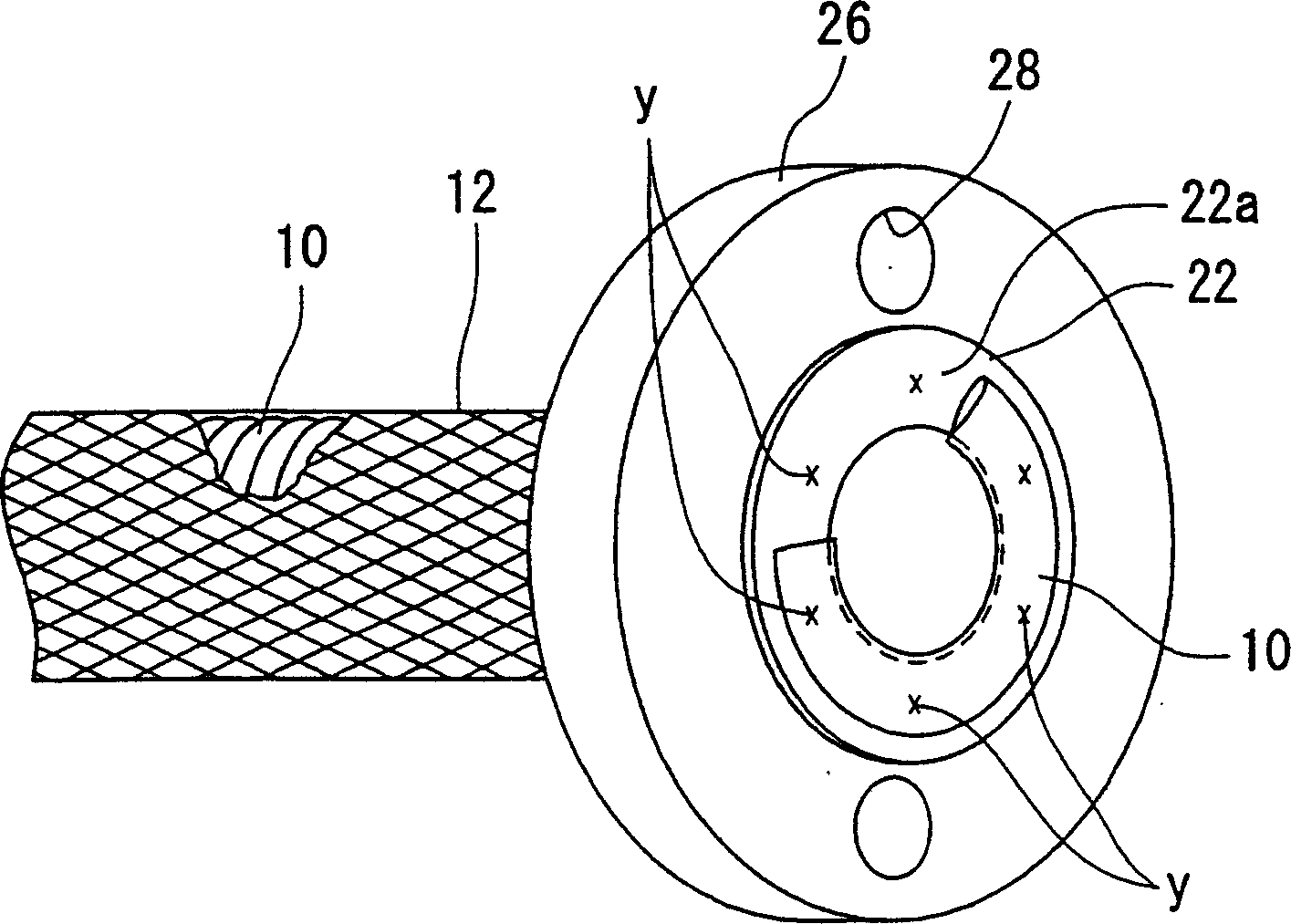

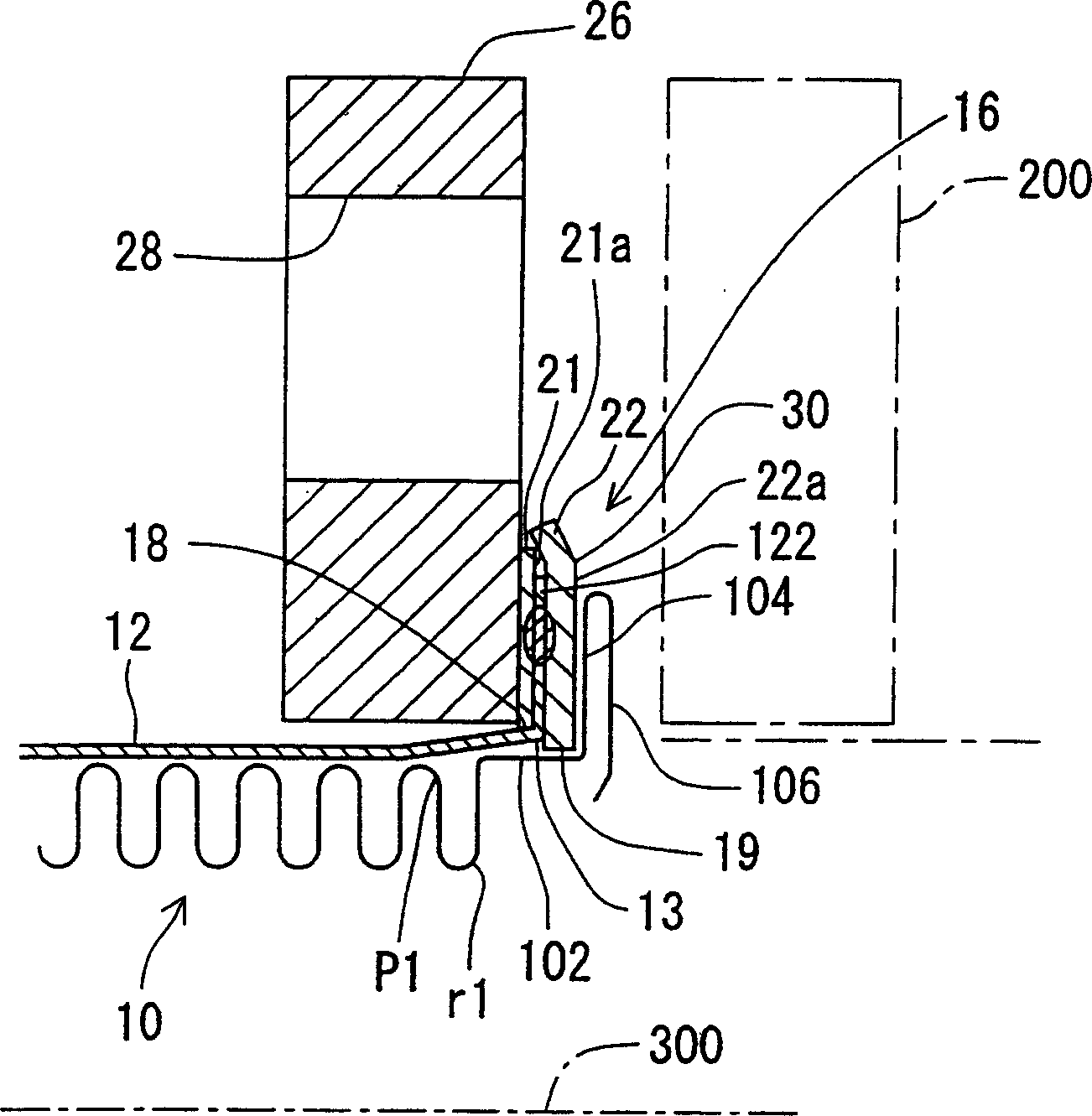

[0021] The structure of the metal flexible hose of the present invention will be described below with an example. Please refer to the attached drawings, and the same symbols will be used for the same components as the original metal flexible hose. figure 1 It is an enlarged explanatory diagram of main parts of the metal flexible hose of Example 1. The metal flexible hose of Example 1 is composed of a bellows 10, a metal mesh 12 covering the bellows, and a metal flexible hose including An integral fixing part 16 including two metal plates 21 and 22 at the ends.

[0022] The corrugated pipe is the same as the original structure. A long stainless steel straight pipe is used as the pipe embryo, and mechanical pressure is applied from the inside or outside of the pipe. At a certain distance, the peak p and the trough r are formed by expanding the drum, repeatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com