Double-sided projection exposure device of belt-shape workpieces

A technology for exposure devices and workpieces, which is applied in the direction of photolithography exposure devices, microlithography exposure equipment, electrical components, etc., and can solve problems such as unrealistic, graphic offset, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

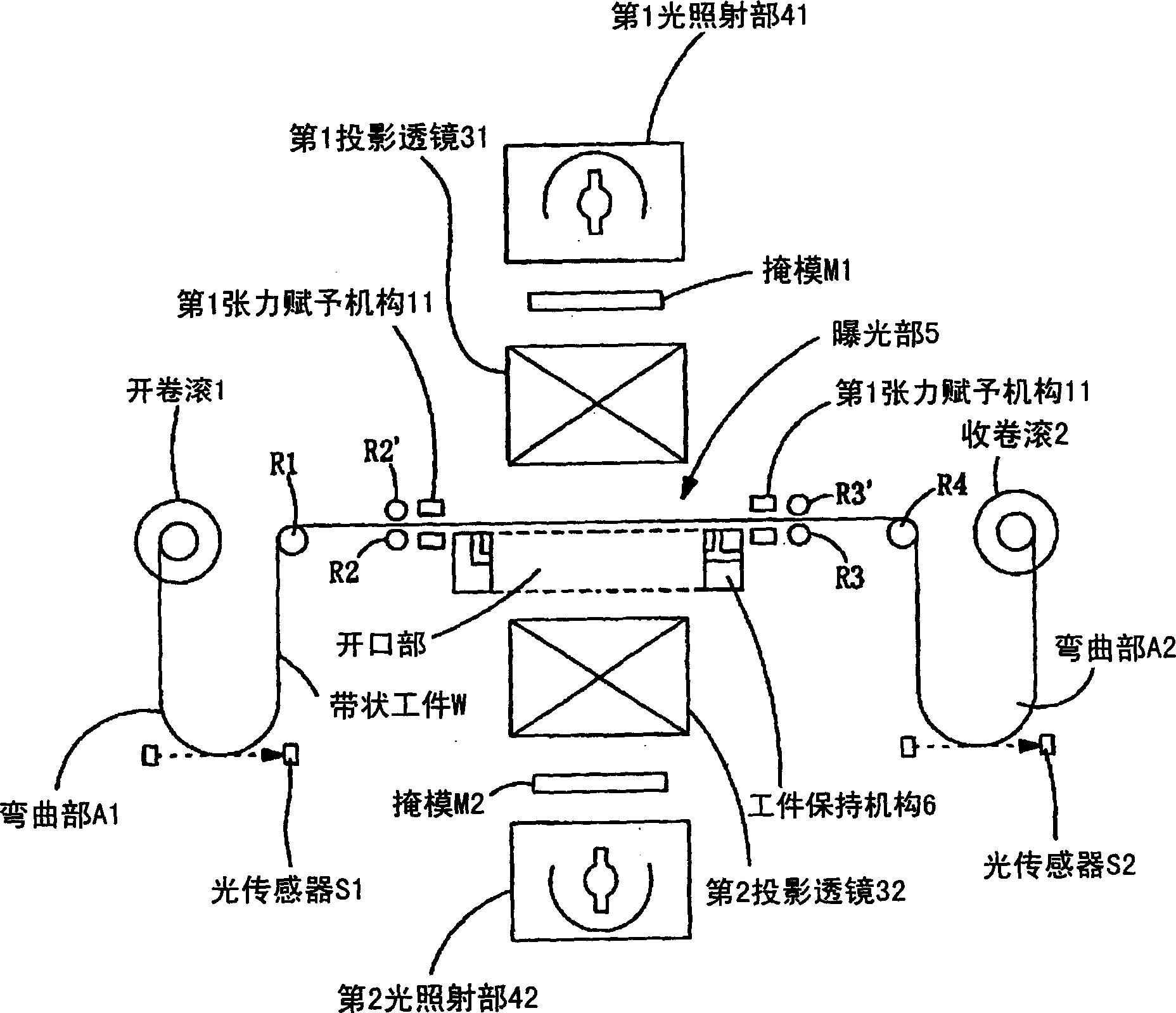

[0056] figure 1 It is a figure which shows the basic structure of the double-sided exposure apparatus of the belt-shaped workpiece which concerns on the Example of this invention. In addition, in figure 1 In , the second mechanism for applying tension in the direction perpendicular to the conveying direction (work width direction) is omitted. In addition, hereinafter, the first and second mechanisms are referred to as first and second tension imparting mechanisms.

[0057] exist figure 1 Among them, a tape-shaped workpiece W such as an FPC (flexible printed circuit board) is wound on an unwinding roll 1 in a roll shape.

[0058] The strip-shaped workpiece W released from the unwinding roller 1 passes through the bending part A1 for adjusting the volume, is turned 90 degrees by the intermediate guide roller R1, passes through the brake roller R2, and is sent into the exposure part 5. The optical sensor S1 is provided in the bending portion A1, and the feeding amount of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com