Toner and method of manufacturing toner

A kind of toner, organic technology, applied in the field of toner, can solve the problems of insufficient durability of toner, weakened wax bleed effect, and decreased offset resistance, so as to improve storage stability and prevent bleed effect from weakening , Improving the effect of offset printing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

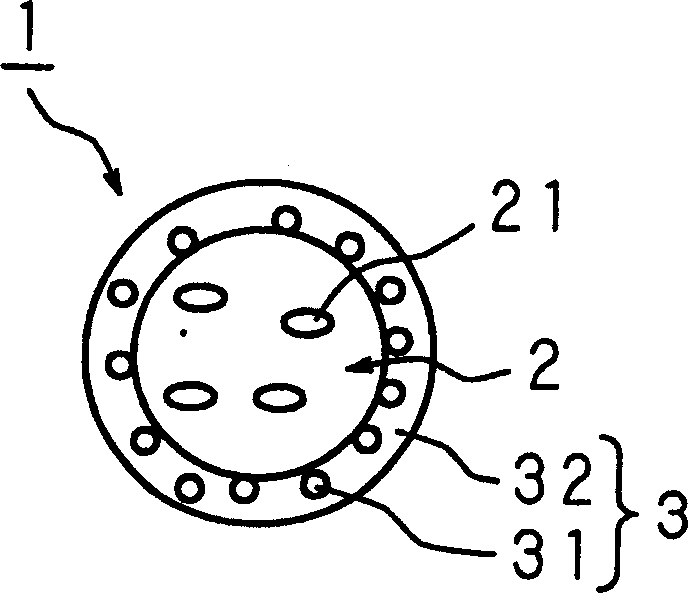

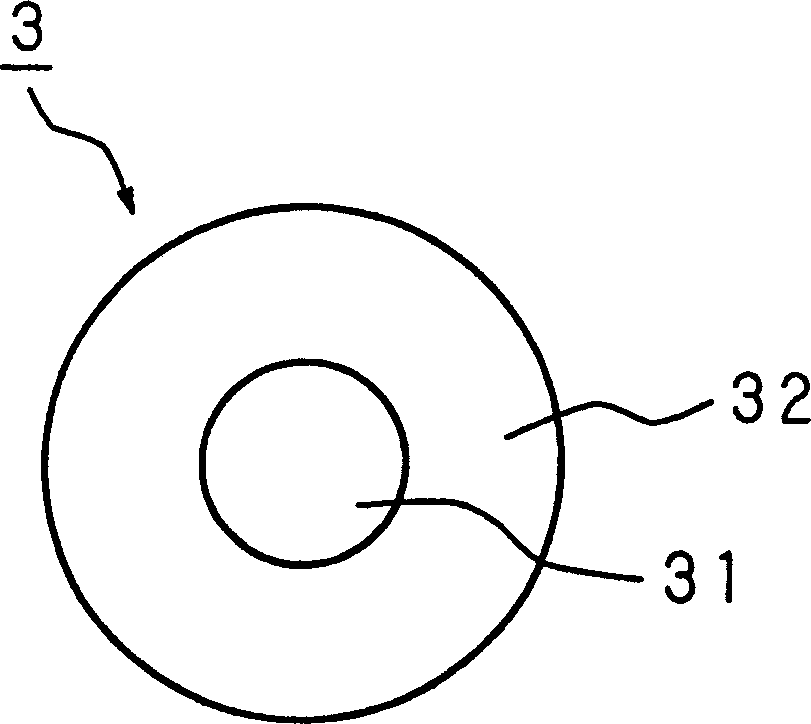

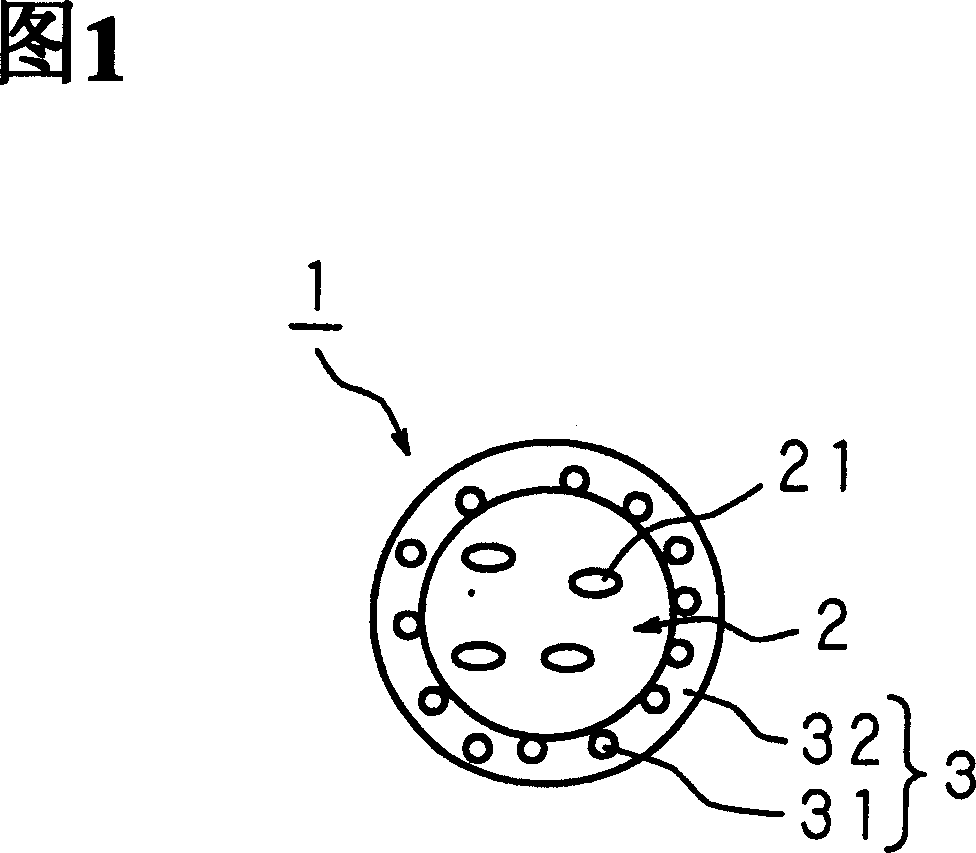

Image

Examples

Embodiment

[0072] Next, the production conditions and evaluation of the toner of the present invention and the toner of the comparative sample produced under various conditions will be described as examples. First, a method for producing organic fine particles required for toner will be described. In addition, the expansion ratio was calculated for the produced organic fine particles. Using DLS-700 (manufactured by Otsuka Electronics Co., Ltd.), the volume average particle diameter La at the stage before the formation of the shell and the volume average particle diameter Lb at the stage of mixing a neutralizing agent to expand it after the formation of the shell were measured, and the expansion was calculated using the following formula 1 Rate.

[0073] Expansion rate = Lb / La...Formula 1

[0074] In the formula, La: volume average particle size before shell formation

[0075] Lb: Volume average particle size after neutralization

[0076] (Organic Microparticles MG-1)

[0077] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com