Polarizing plate protective film, production method for same, and polarizing plate

A manufacturing method and technology of polarizers, which are applied in polarizing elements, semiconductor/solid-state device manufacturing, identification devices, etc., can solve problems such as difficulty in improving slidability, large haze of polarizer protective film, and insufficient slidability effects, etc., to achieve Eliminates deterioration of haze, good handling properties, and high production adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

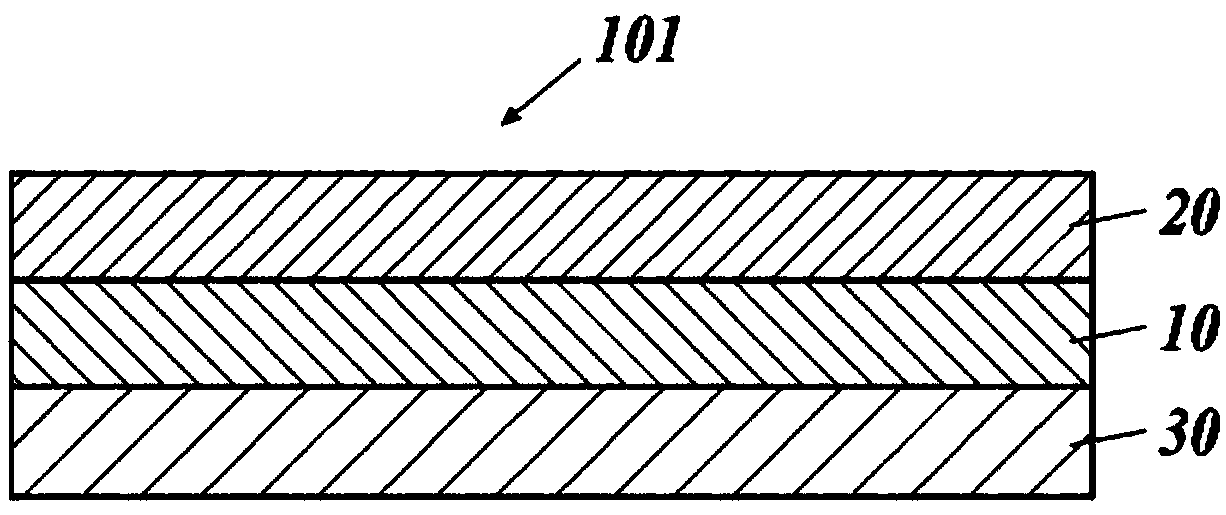

[0241] Polarizer protective film (Hereinafter, simply referred to as "protective film".)

[0242]

[0243] (Preparation of microparticle dispersion a)

[0244] 90 parts by mass of ethanol was put into an airtight container, and 10 parts by mass of silicon oxide fine particles a (manufactured by Nippon Aerosil Co., Ltd.) listed in Table 1 were added with stirring. Then, after stirring and mixing in the dissolver for 50 minutes, the above-mentioned 2000g mixed solution was passed through a high-pressure dispersion device (trade name: ultra-high pressure homogenizer M110-E / H, manufactured by Microfluidics Corporation), and 1 treatment was carried out at 175Mpa. Thus, a fine particle dispersion liquid a was prepared.

[0245] (Preparation of microparticle additive solution A)

[0246] The obtained fine particle dispersion a was slowly added to a closed container containing dichloromethane while stirring well. Further, dispersion is carried out by an attritor. This was filter...

Embodiment 2

[0308]

[0309] On one side (A side) of the polarizer 1, the protective film 101 is bonded in a direction parallel to the transmission axis of the polarizer 1 by a PVA-based adhesive, and on the other side (B side) of the polarizer 1 The following protective film 203 was bonded to the surface) to obtain a polarizing plate 301 . As described in Table 3, except having combined the protective film and the polarizer, it carried out similarly to the polarizing plate 301, and produced the polarizing plate 302 - the polarizing plate 326.

[0310] Protective film 201

[0311] (Polyethylene naphthalate film, TEONEX Q83 (trade name) (manufactured by Teijin DuPont Co., Ltd.), thickness: 40 μm)

[0312] Protective film 202

[0313](Polyethylene terephthalate film, MRF40 (trade name) (manufactured by Mitsubishi Plastics Corporation) Thickness: 25 μm)

[0314] Protective film 203

[0315] (Triacetyl cellulose film, KC4UAW (trade name) manufactured by Konica Metanon Co., Ltd., thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com