Fixed type electrode tip removal device

A technology for dismantling devices and electrode heads, which is applied in the direction of auxiliary devices, electrode features, resistance welding equipment, etc., can solve the problems that the electrode head requires physical strength, cannot realize labor saving and complete automation, and achieves the effect of labor saving and reliable disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

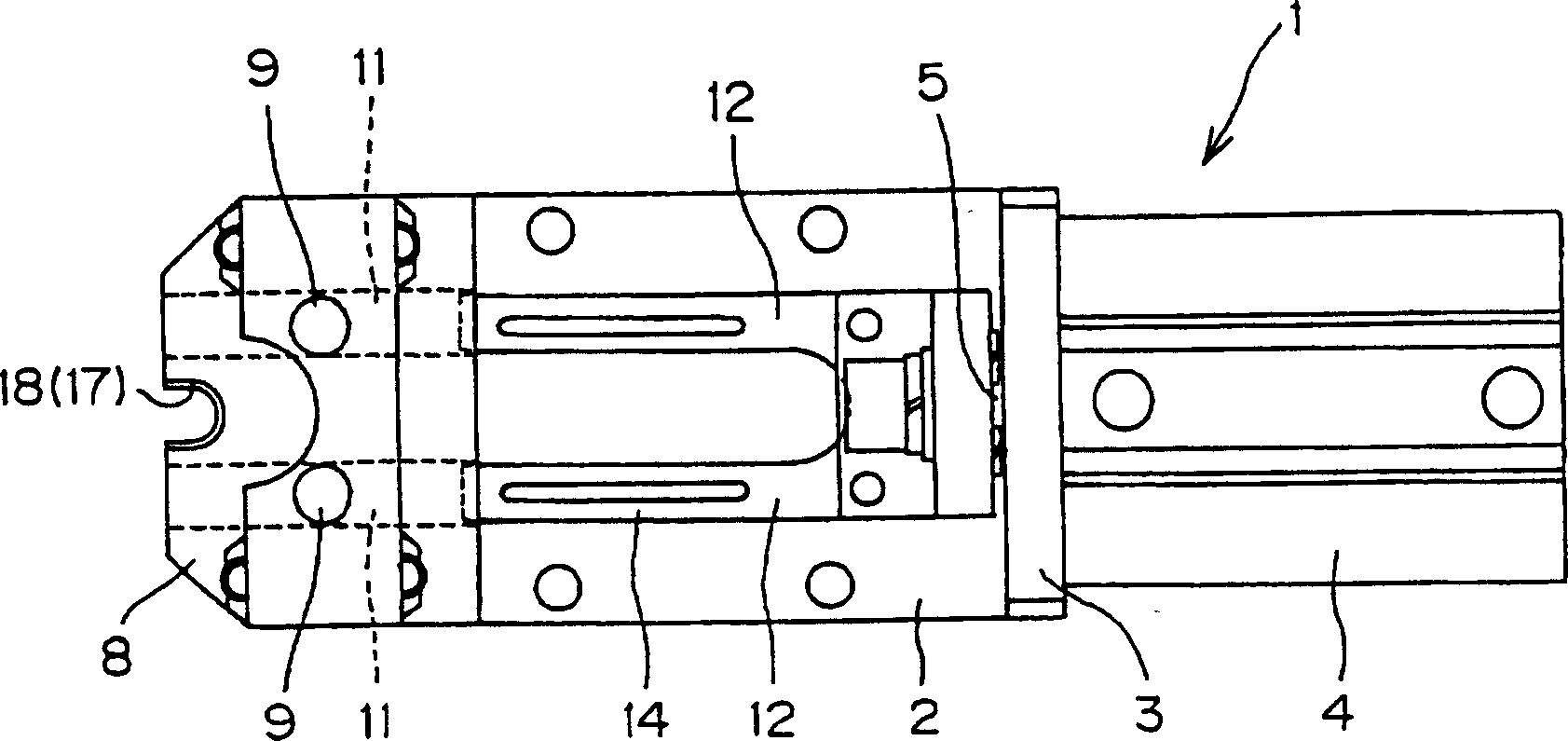

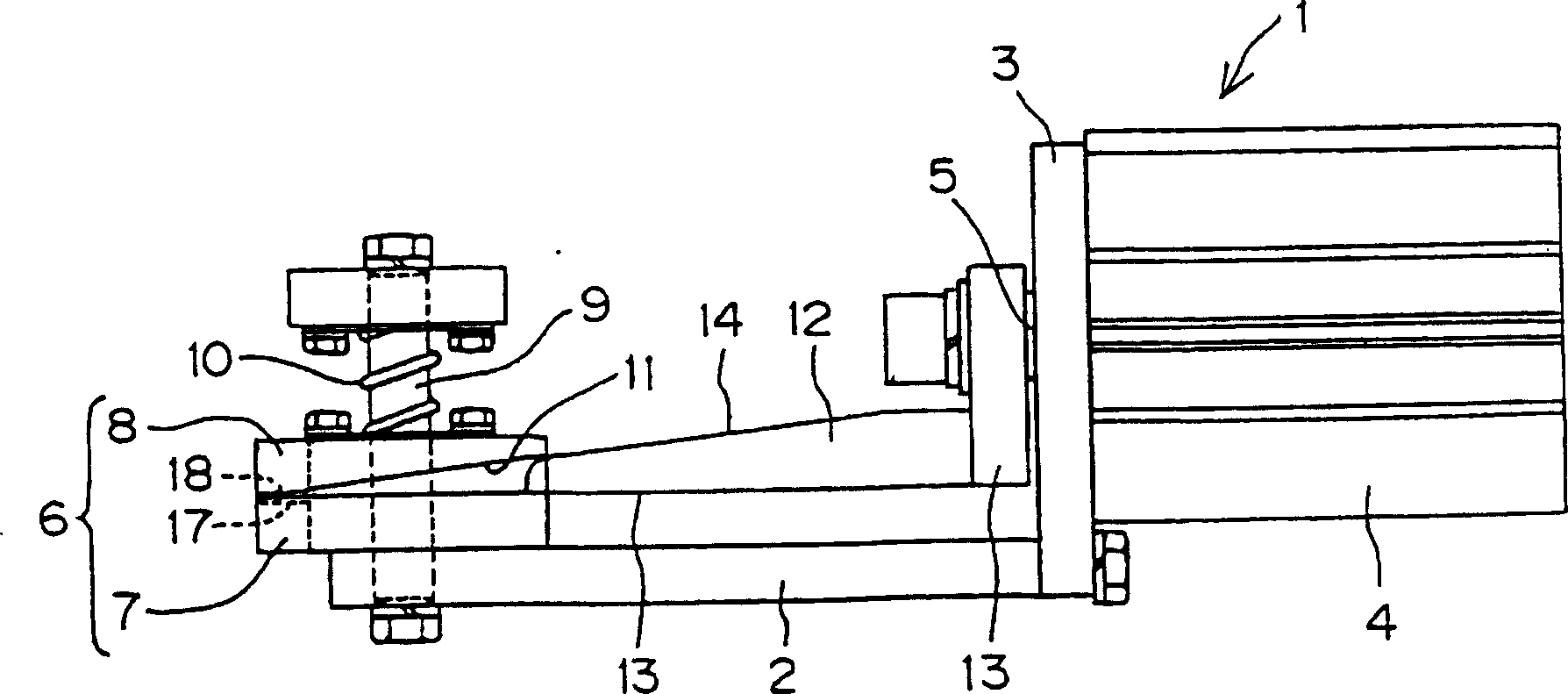

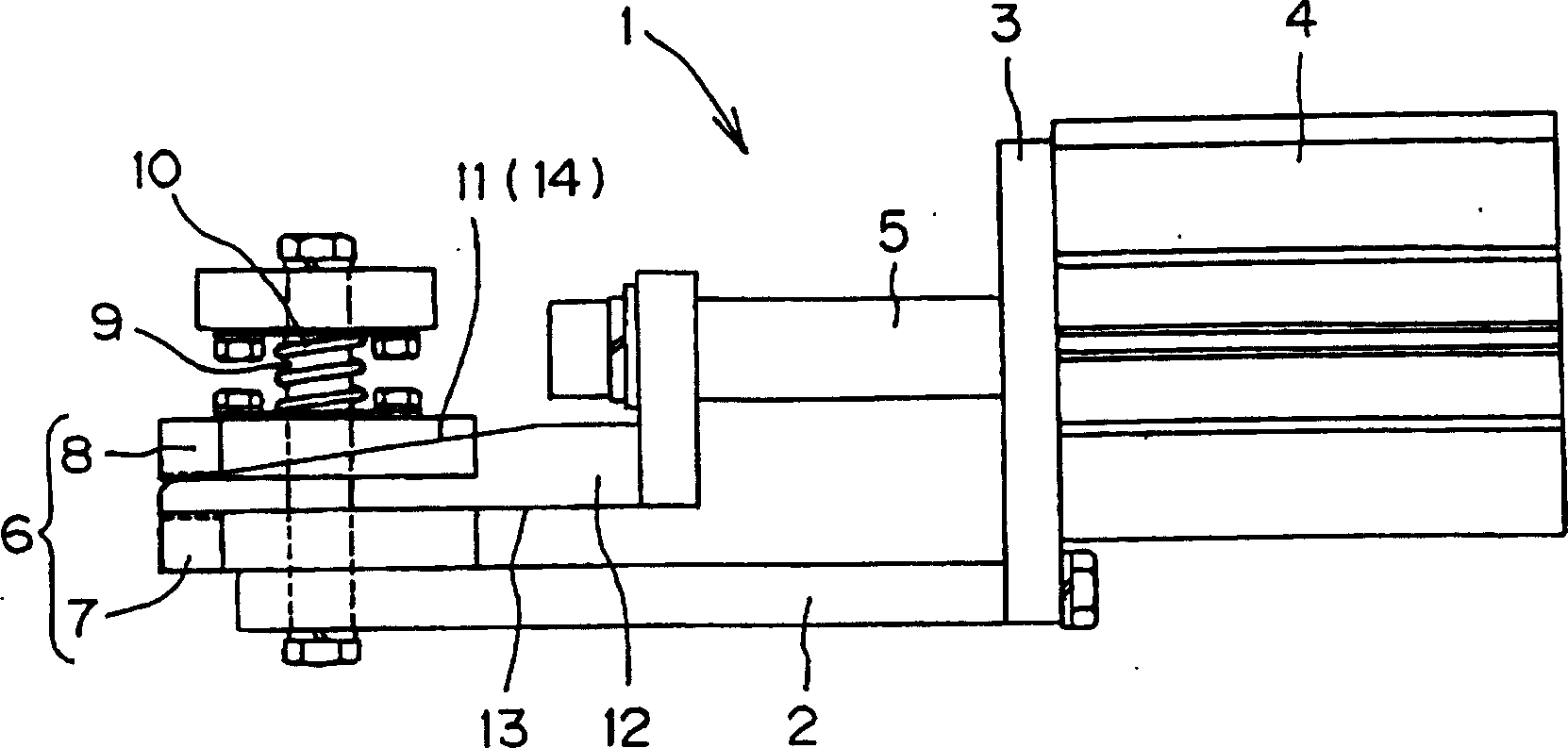

[0028] Figure 1 ~ Figure 4 It relates to the fixed electrode tip removal device of the first embodiment of the present invention. figure 1 is the top view of the main part, figure 2 is its front view, image 3 It is an action explanatory diagram, Figure 4 It is an explanatory diagram for setting the electrode tip on the electrode tip removal device.

[0029] In the figure, 1 represents the overall view of the fixed electrode head removal device, on which a drive device 4 is installed on the base 2 of the fixed electrode head removal device 1 through a bracket 3 . As the driving means 4, a known driving mechanism such as reciprocating movement of the cylinder pressurizing rod 5, reciprocating movement of the pressurizing rod 5 by means of a motor extending from a motor and including a screw and a nut can be suitably used.

[0030] 6 is a detachment claw member, which is composed of a fixed detachment claw member 7 fixed on the base plate 2 and a movable detachment claw m...

no. 2 example

[0040] Figure 5~ Figure 7 Referring to the fixed electrode tip removal device according to the second embodiment of the present invention, Fig. 5 is a front view of main parts, Figure 6 is its left side view, Figure 7 It is an explanatory diagram for setting the electrode tip on the electrode tip removal device.

[0041] In this second embodiment, the dismounting claw members are arranged in upper and lower layers, and the upper and lower layers of wedges are used to make these dismounting claw members move simultaneously, which is different from the above-mentioned first embodiment, and other structures are essentially the same Since the examples are the same, the same components are given the same reference numerals and their descriptions are omitted.

[0042] That is to say, the dismounting claw member 6 is arranged in upper and lower layers, the dismounting claw member 6 of the upper layer makes the fixed dismounting claw member 7 be located at the upper part, the mov...

no. 3 example

[0047] Figure 8 ~ Figure 10 Relating to the fixed electrode tip removal device of the third embodiment of the present invention, Figure 8 is the main part front view, Figure 9 and Figure 10 is an explanatory diagram of its operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com