Method for setting offset set value of warp take-up device and warp take-up device

A technology of coiling device and setting value, used in warping machines, transportation and packaging, other manufacturing equipment/tools, etc., can solve the problems of disordered coiling posture, unavailability, cracking of weaving shafts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

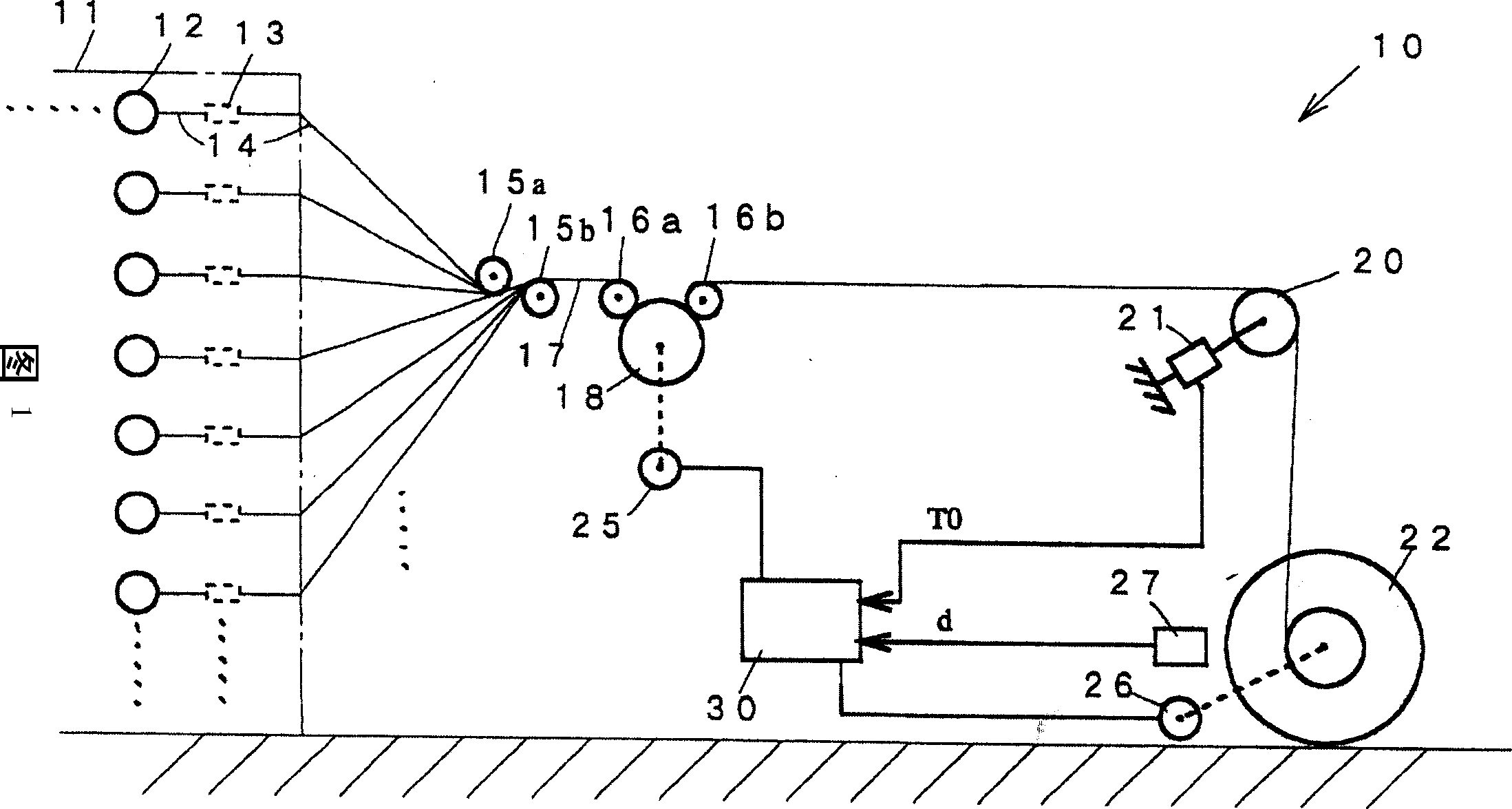

[0022] Embodiments of the present invention will be described below with reference to the drawings. Fig. 1 shows the whole of a warp winding device 10 installed in a factory. Generally speaking, the warp yarn winding device 10 includes: a warp creel 11 that is loaded with many yarn supply bodies 12; and a winding shaft 22 for winding the warp yarn sheet 17.

[0023] On the beam creel 11, a plurality of yarn supply bodies 12 are arranged side by side in the up-down, left-right, and front-back directions, and a tensioner 13 is provided on each yarn supply body. Also, between the creel 11 and the rotatable tension roller 18 arranged in front of it, a pair of guide rollers 15a, 15b that overlap each other in the vertical direction and are separated are arranged. Adjacent guide rollers 16a, 16b. The warp yarn 14 drawn out from each yarn supply body 12 through the tensioner 13 is formed into a warp yarn sheet 17 by making a pair of guide rollers 15a, 15b combined into one, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com