Automatic directional valve device

An automatic reversing and valve device technology, applied in the direction of valve devices, valve operation/release devices, water supply devices, etc., can solve the problems of many components and increased manufacturing difficulty, so as to reduce the number of components, reduce the difficulty of assembly, The effect of improving the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is a detailed description of the automatic reversing valve device according to the drawings in the appendix.

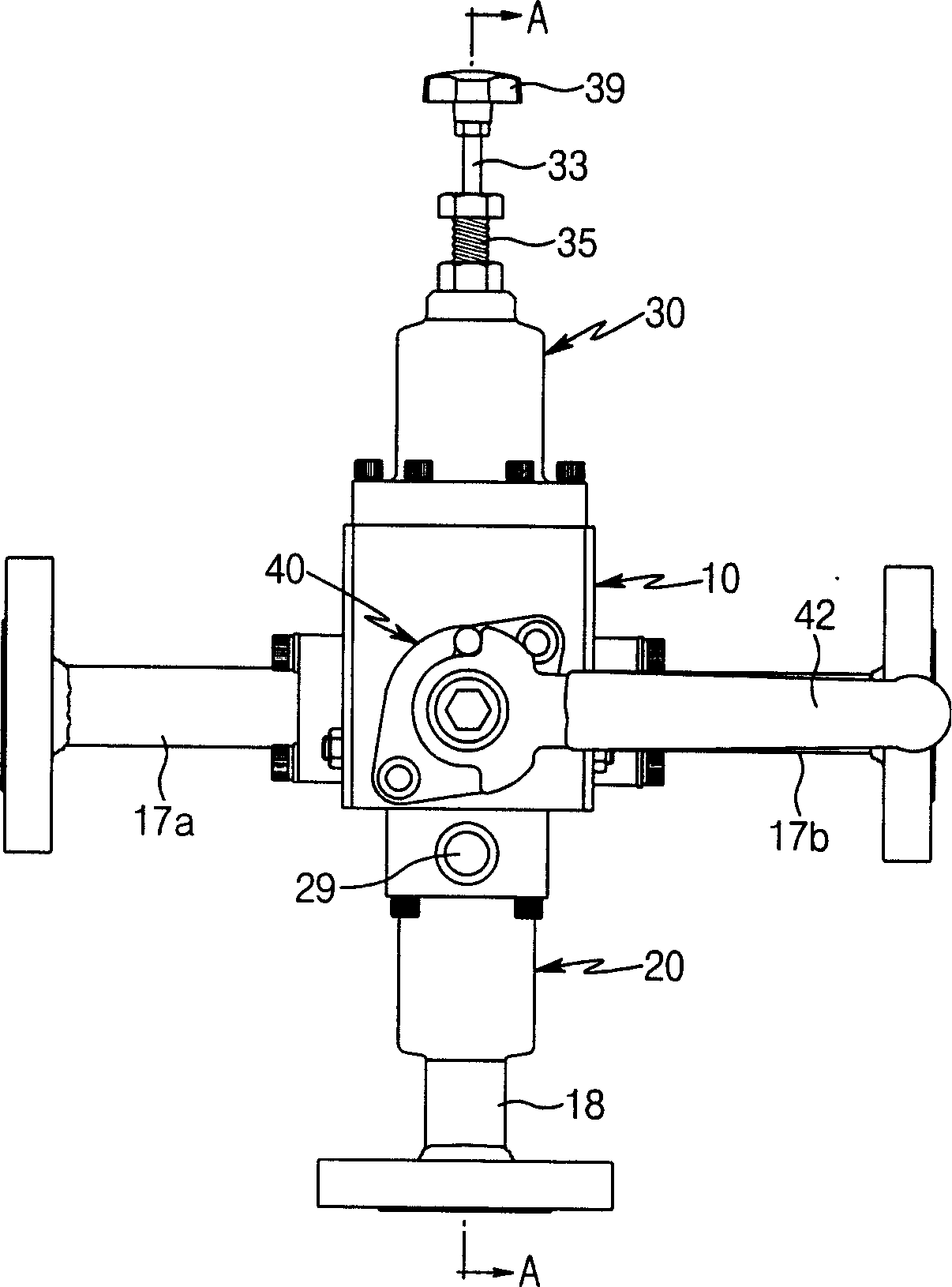

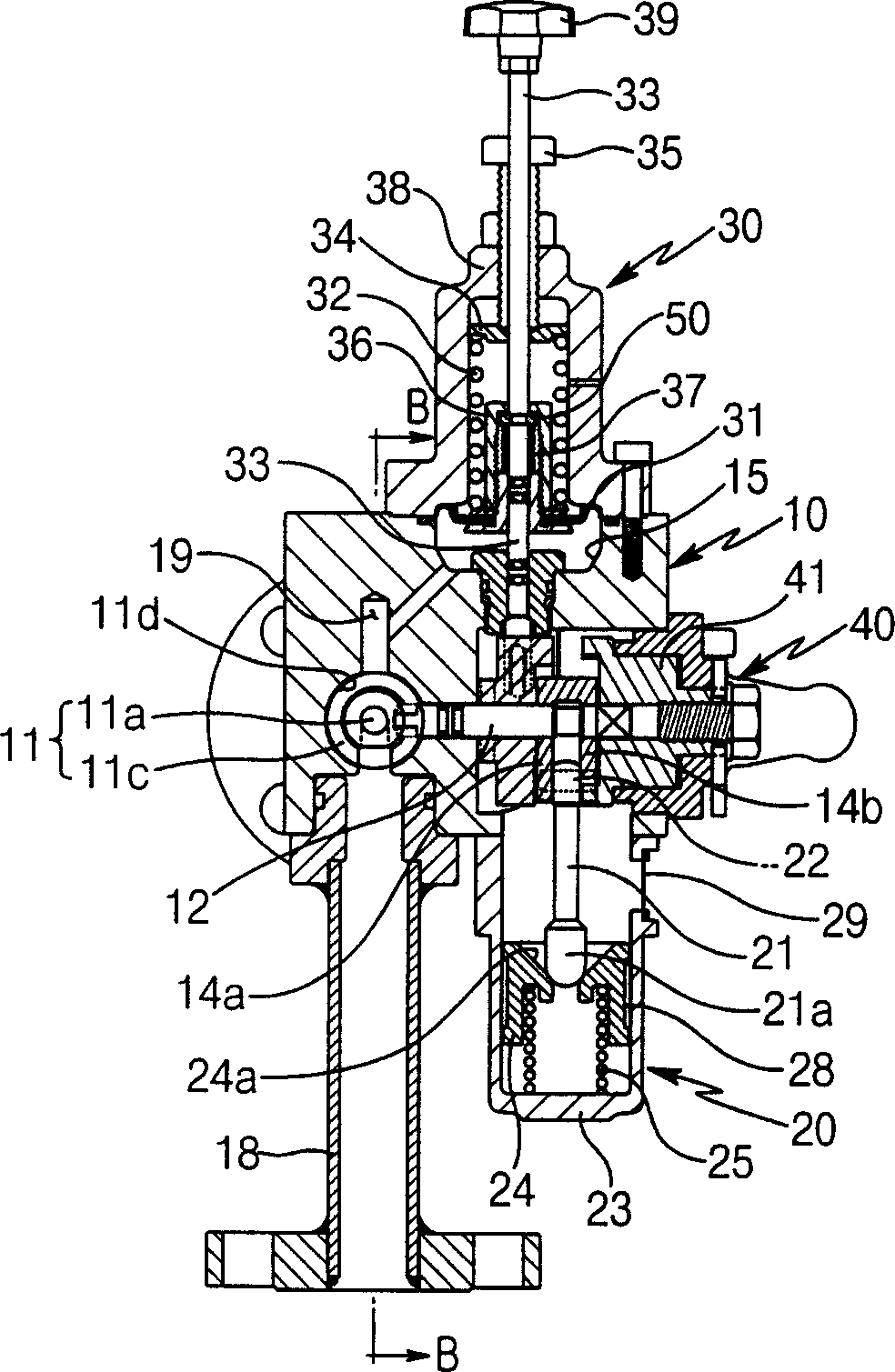

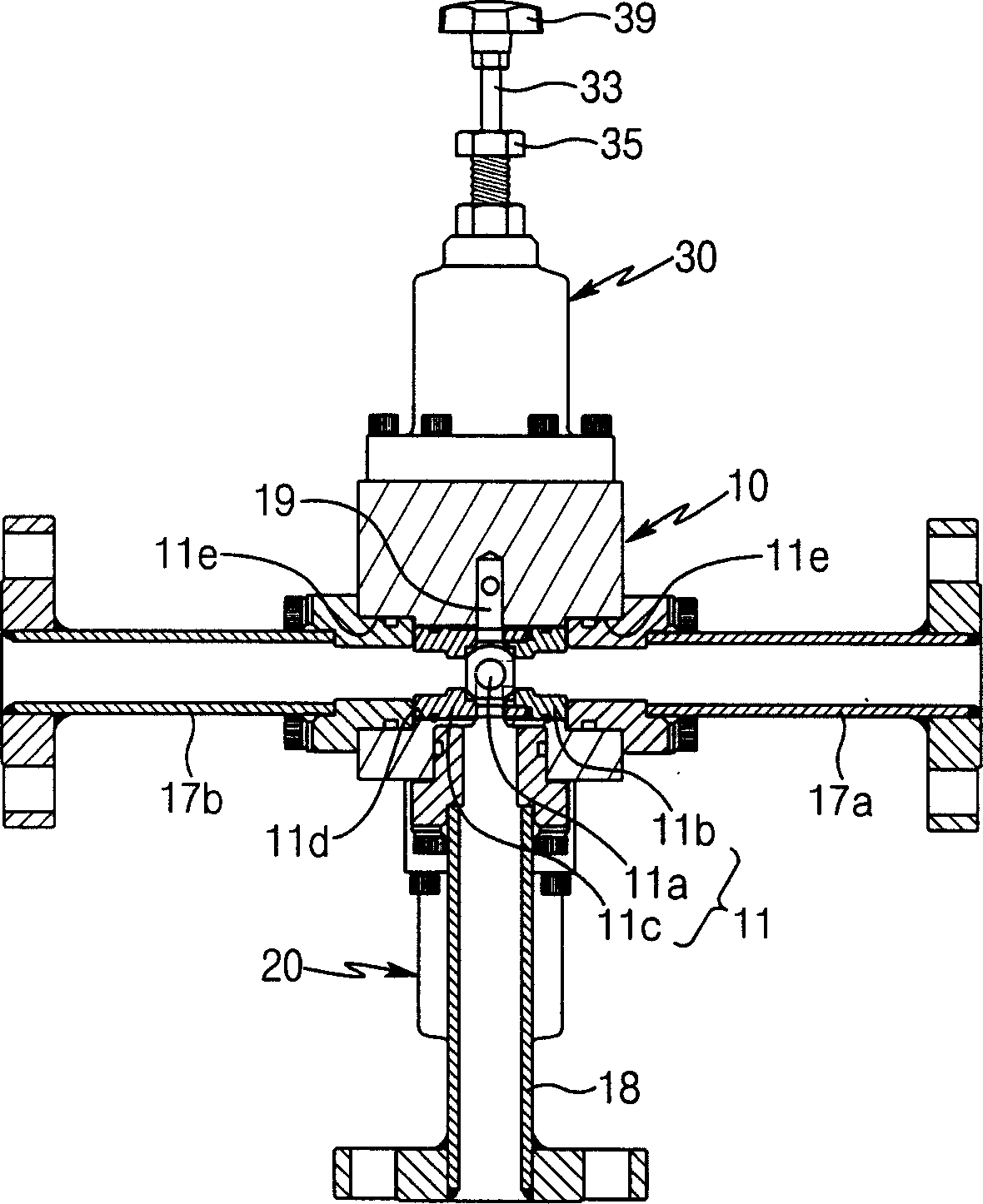

[0035] Figure 1 to Figure 6 It is the overall / partial schematic diagram of the LPG automatic reversing valve device in the present invention.

[0036] As shown in the figure, two LPG supply pipes 17a, 17b and an output pipe 18 are provided on the reversing body 10, and the LPG is output to the vertical steam pipe through the supply pipe 17a, 17b, and the C circuit through the output pipe 18. equipment. The bottom, top and front of the reversing body 10 are respectively fixed with a link mechanism 20 , a control die mechanism 30 and a reset mechanism 40 .

[0037] Such as figure 2 As shown, one side of the reversing body 10 forms a valve chamber 11d that communicates with the supply pipes at both ends of the reversing body 10. There are two concentric holes 11e that communicate with the supply pipes 17a and 17b at both ends of the valve chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com