Pattern inspection method and apparatus, and pattern alignment method

An inspection method and pattern technology, applied in functional inspection, image analysis, image data processing, etc., can solve problems such as pattern defects and loss of defective patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

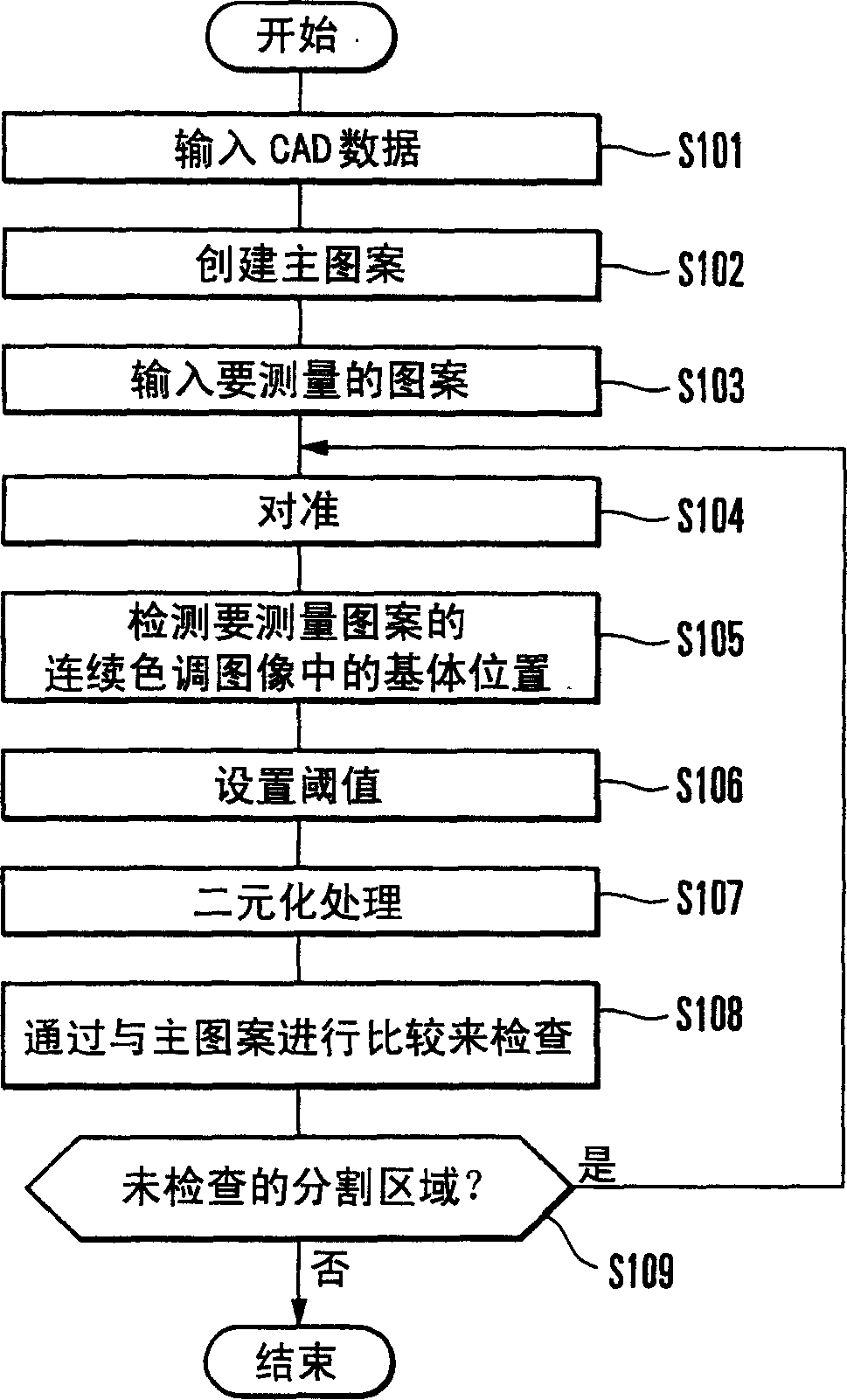

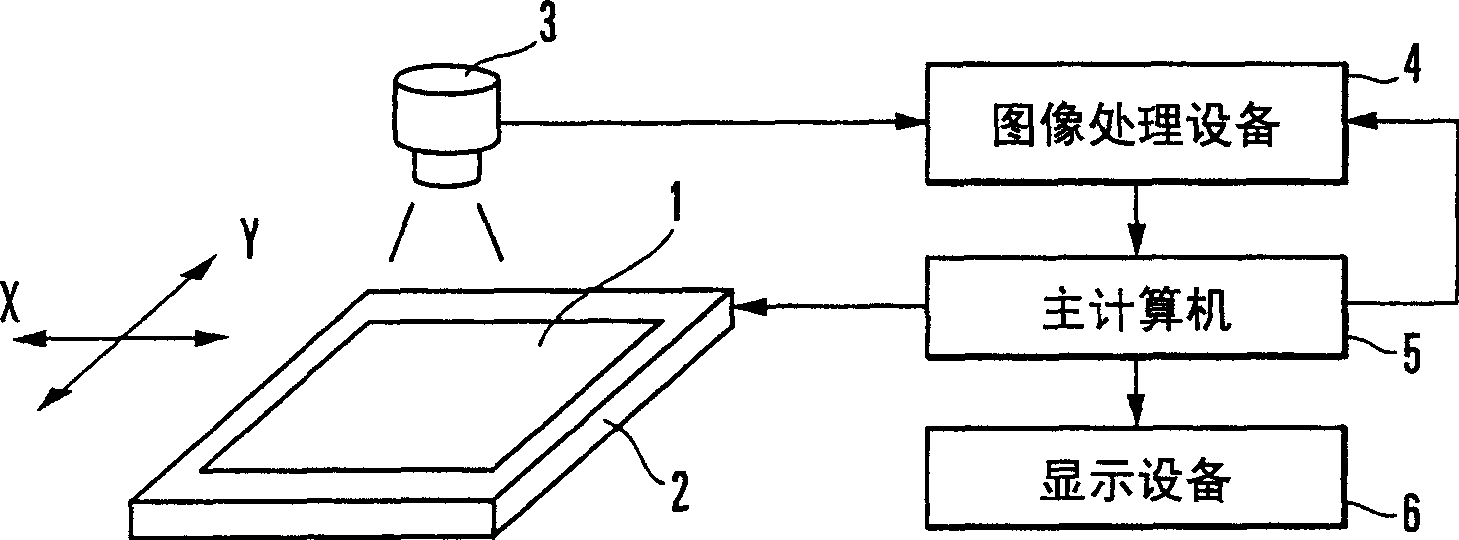

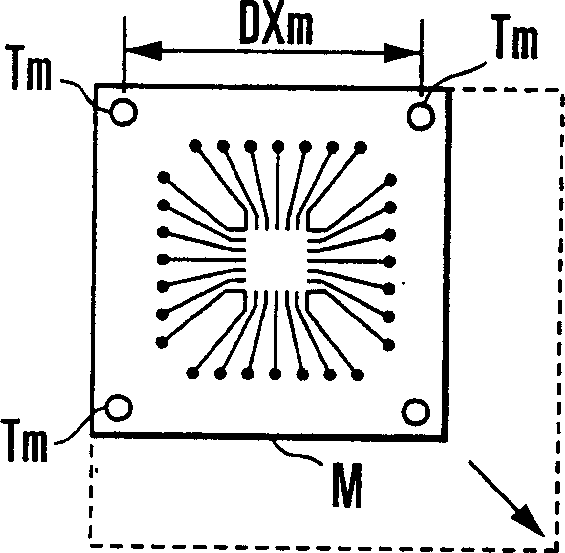

[0045] A first embodiment of the present invention will be explained in detail below with reference to the drawings. figure 1 A pattern detection method according to a first embodiment of the present invention is shown. figure 2 A pattern inspection device used in this inspection method is shown. exist figure 2 In, reference numeral 1 denotes an inspection workpiece such as a printed circuit board; reference numeral 2 denotes an X-Y table supporting the inspection workpiece 1; reference numeral 3 denotes a line sensor camera for sensing the inspection workpiece 1; reference numeral 4 denotes a main The pattern is compared with the pattern to be measured perceived by the camera 3, and an image processing device that checks the pattern to be measured; reference numeral 5 denotes a host computer that controls the entire device; and reference numeral 6 denotes a display device that displays the inspection result.

[0046] The image processing apparatus 4 includes: alignment m...

no. 2 example

[0107] In the first embodiment, the continuous tone image data of the pattern to be measured is binarized at the threshold SH1 at which the difference from the density value of the base is always kept constant. However, binarization with a single threshold SH1 may miss pattern defects even if no density change has occurred.

[0108] like Figure 10 As shown, the density value of the defect or disconnected part is higher than the density value of the matrix and close to the density value of the conductor. On the contrary, the density value of the protruding portion or the short-circuit portion is smaller than that of the conductor and close to that of the matrix. For this reason, binarization with a single binarization threshold SH1 converts a defect such as a chip or a disconnection into "1", and converts a defect such as a protrusion or a short into "0". Even for Figure 10 Inspections performed on the binarized results are also unable to detect such defects.

[0109] As ...

no. 3 example

[0118] In the first and second embodiments, the threshold is set so that the difference from the density value of the matrix is always constant. It is also possible to set the threshold so that the ratio of the difference between the threshold and the density value of the matrix to the difference between the density values of the conductor and the matrix is always constant.

[0119] When the threshold value setting method of the third embodiment is applied to the first embodiment, the host computer detects the positions of the substrate and the conductor in the continuous tone image of the pattern to be measured ( figure 1 in step S105). Similar to the base position, the conductor position can also be obtained from the master pattern aligned in step S104. Such as Figure 13A As shown, the host computer 5 sets the threshold SH1 so that the ratio DF1 / DF4 of the difference DF1 between the threshold SH1 and the density value of the matrix to the difference DF4 between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com