Layer testing technology and apparatus for loose sand gas-field gas-production well oil-casing

A layered testing, oil casing technology, applied in surveying, earthmoving, wellbore/well components, etc., can solve the problems of long stabilization time, complex operation procedures, expensive instruments, etc., to achieve low cost and improve the corresponding relationship , The effect of on-site construction is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

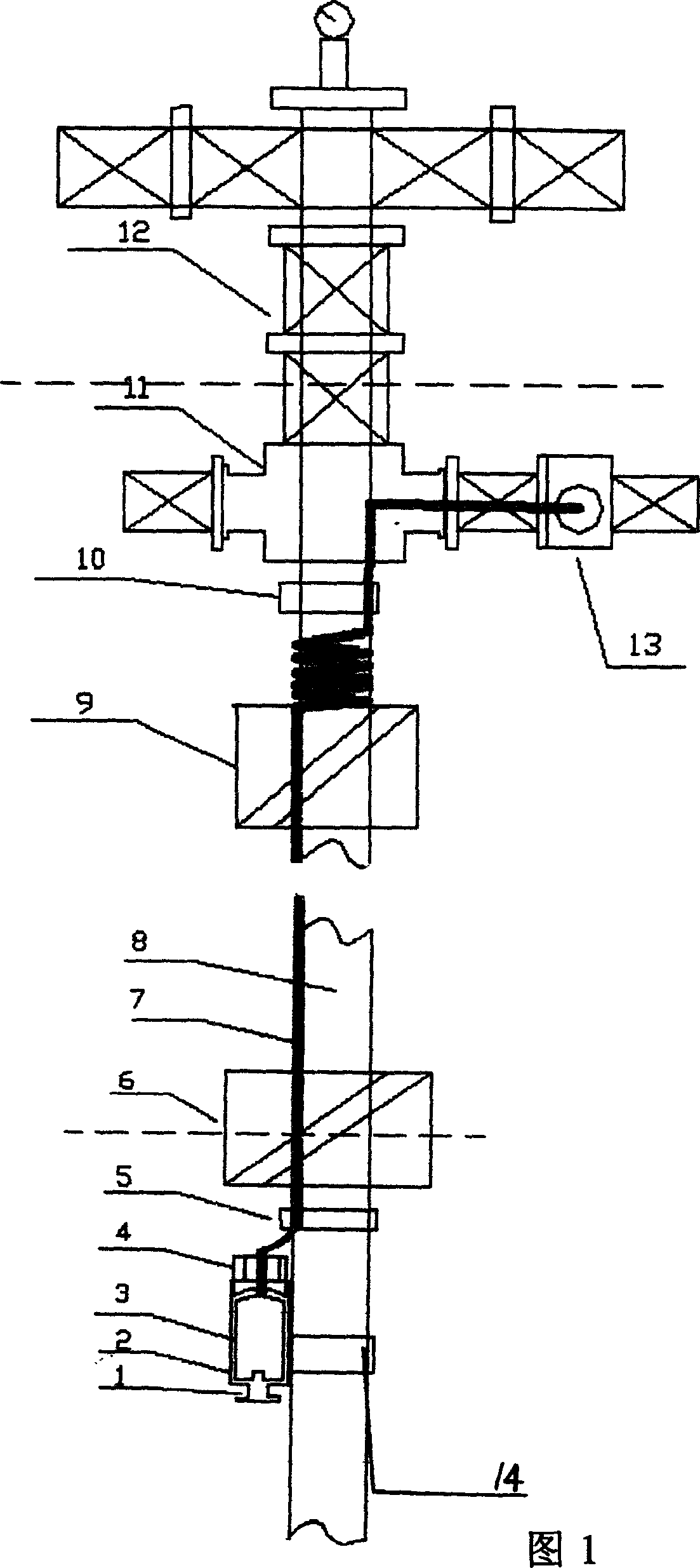

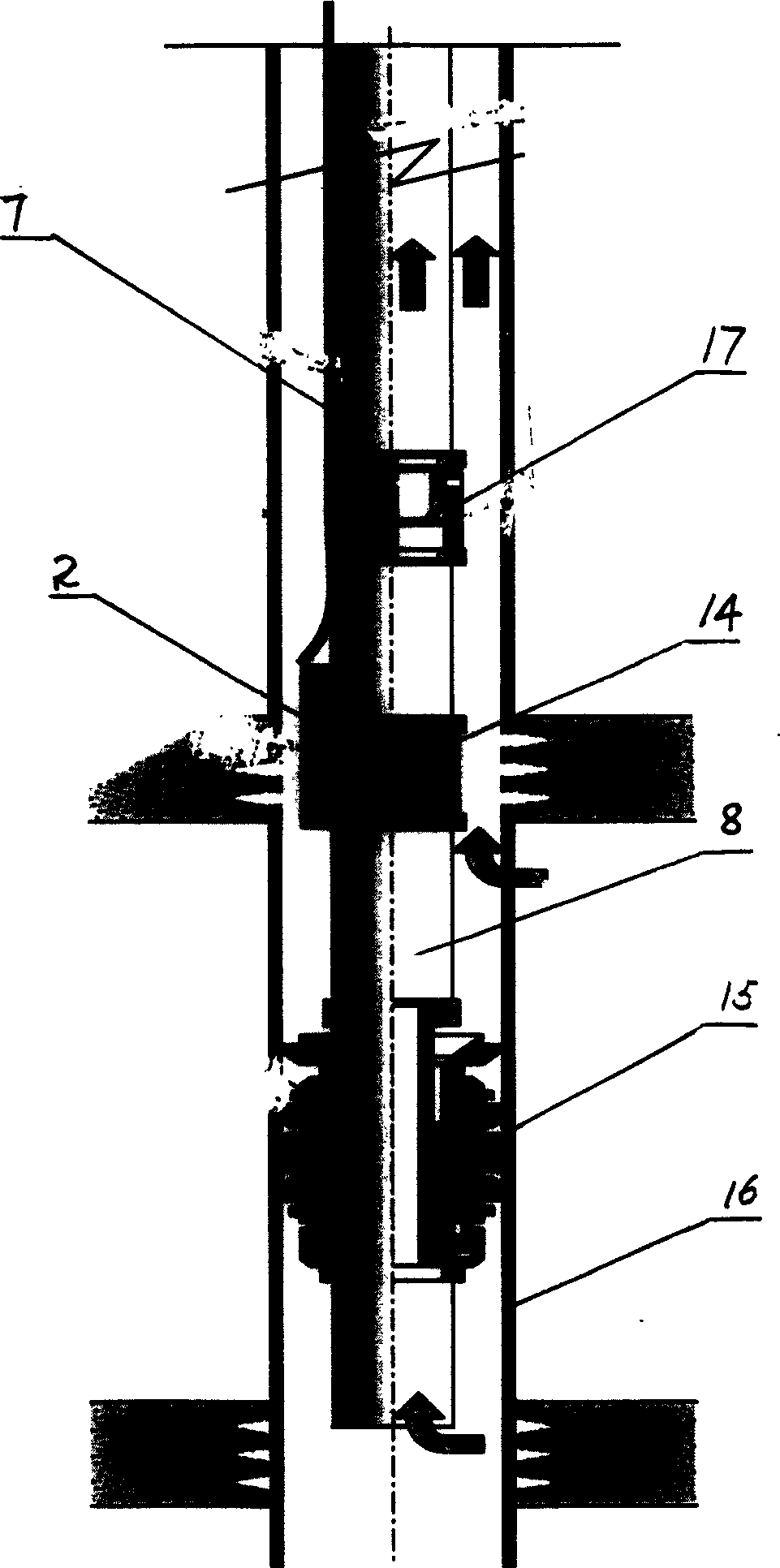

[0022] Clamp the Y341 packer (15) with the slip switch (17) on the outer lower end of the tubing (8), and go down from the tubing and casing (16) to the middle of the two gas layers to be separated along with the tubing, and the cable ( 7) Pass the cable gland cover (4) on the sheath (2) connected to the positioning card (14) to connect with the pressure gauge probe (3), put the pressure gauge probe into the pressure gauge sheath, and put the sheath The gland (1) compresses the pressure gauge probe, and the pressure gauge probe is sealed and insulated with two layers of steel sleeves and epoxy resin to prevent short circuit caused by formation water erosion. Use hexagon socket bolts to fix the positioning card on the upper part of the packer, the downhole is the middle part of the gas layer (calculated), and start to go downhole. In order to protect the cable from being damaged during the downhole process, two cable clamps (5), (10) are used for each section of oil pipe to fix...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap