Method for positioning first-on rotor for alternating current permanent-magnet synchronous motor control system

A permanent magnet synchronous motor and motor rotor technology, applied in control systems, electronic commutation motor control, electrical components, etc., can solve problems such as long positioning time, wrong positioning, and complex systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

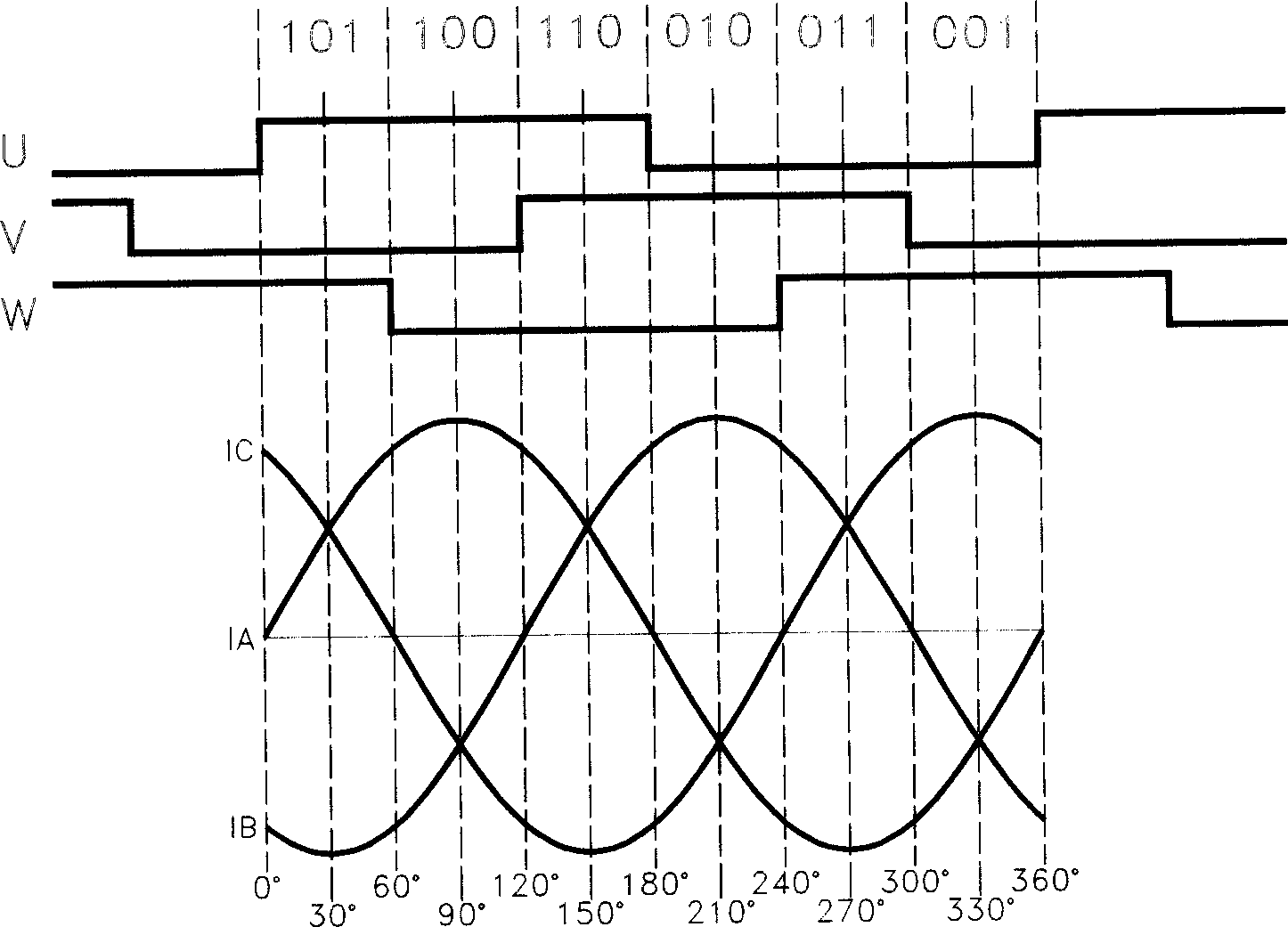

[0010] Install an ordinary incremental encoder on the rotor of the motor, and use the number of A and B pulses it outputs to represent the change of the rotor position. At the same time, when the motor is manufactured, the induction Hall element of the rotor magnetic pole position is pre-installed and equipped with a common incremental encoder, or a special incremental encoder with U, V, W signals is installed. Such as figure 1 As shown, the U, V, and W state signals sent by the Hall element or the encoder have a total of six level states, 101, 100, 110, 010, 011, and 001, which represent the electrical angle position of the motor rotor. Six equidistant interval, each interval is 360÷6=60° electrical angle. At the initial power-on moment, the U, V, and W signal states sent by the incremental encoder determine the interval where the initial position of the rotor magnetic field vector of the motor is located. The midpoint of this interval is taken as the rotor magnetic field ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com