Cement core pipe for cast-in-situs hollow floorslab

A hollow-core slab and cement technology, which is applied to the on-site preparation of slabs, formwork/formwork/work frame, and building components, can solve problems such as dislocation, deterioration of the stress state of hollow-core slabs, and reduce weight and production. Process, saving prefabrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

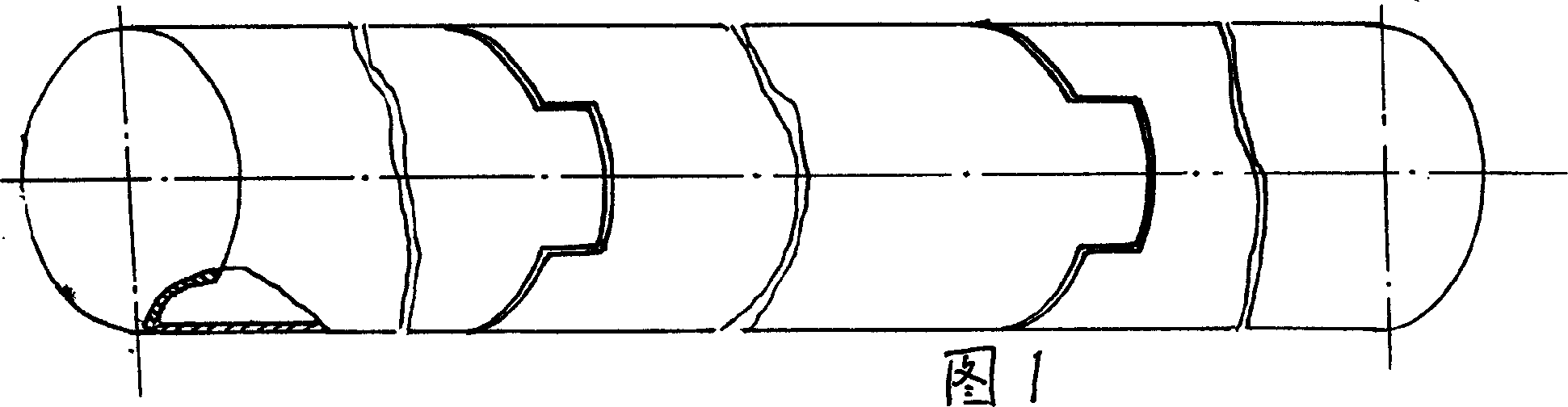

[0025] Embodiment 1, as shown in Figure 1, it is formed by the coaxial connection of three cement thin-walled pipes, wherein the ends of the thin-walled pipes located on the left and right sides have end caps, and the rest without end caps The end wall of the thin-walled tube is provided with three rectangular teeth with equal pitch and capable of meshing with each other;

Embodiment 2

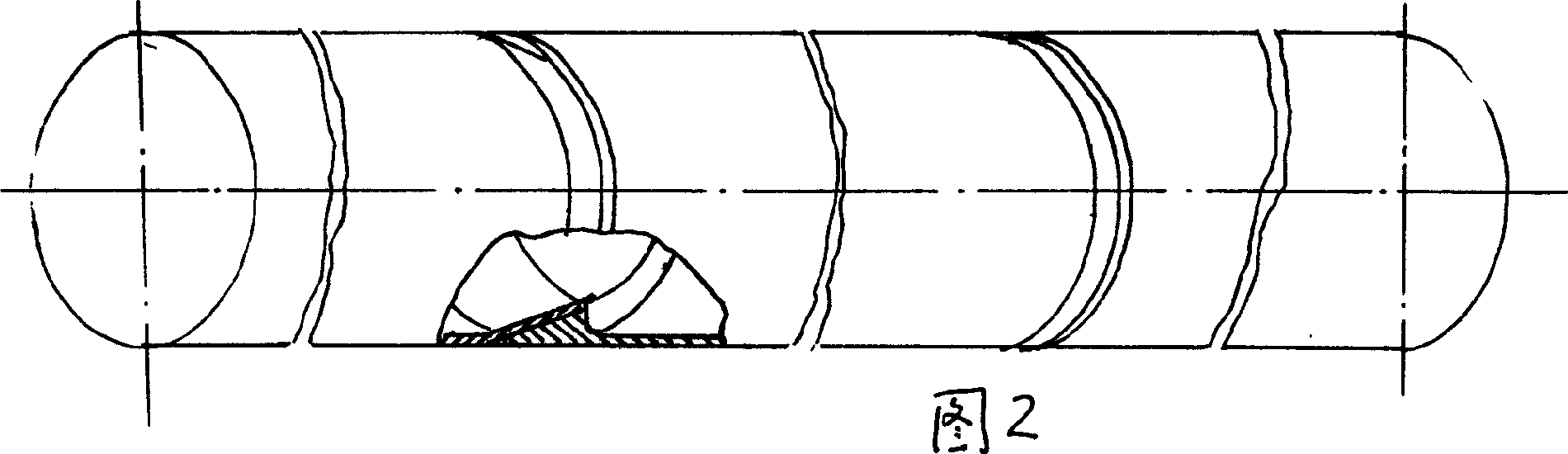

[0026] Embodiment 2, as shown in Figure 2, is also formed by coaxial connection of three cement thin-walled pipes, wherein the left end of the thin-walled pipe on the left has an end cap, and the pipe wall at the right end is small on the outside and large on the inside. Conical tube; the right end of the thin-walled tube on the right has an end cap, and the tube wall at the left end is a conical tube with a large outside and a small inside; the right end of the thin-walled tube in the middle is a conical tube with a small outside and a large inside. And its left end pipe wall is the conical tube with big outside and small inside.

[0027] The manufacture method of the cement core pipe used when pouring the hollow floor slab described in embodiment 1 of the present invention:

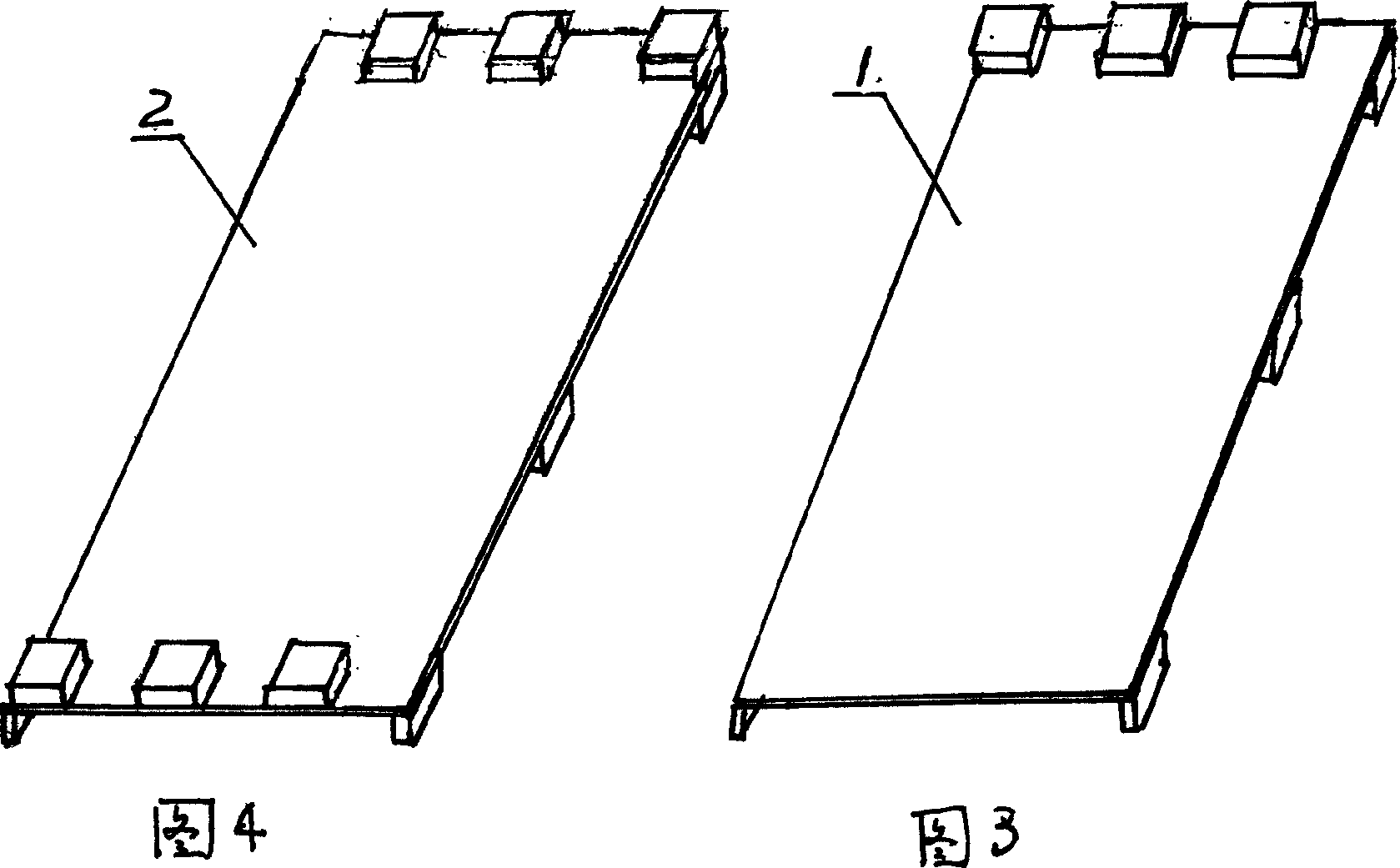

[0028] A. Make the thin-walled tubes located on the left and right sides, unfold the outer formwork 1, and one end is provided with at least three rectangular teeth with equal tooth pitch and capable of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com