Air conditioner with indoor unit with automatic cleaning air filter

An air filter and air conditioner technology, which is applied in the direction of cleaning methods using gas flow, air conditioning systems, and dispersed particle filtration, etc., can solve the problems of large output of suction devices, power consumption, and difficult suction device built-in, etc., to achieve smooth drive, Reduce installation, good effect of suction and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

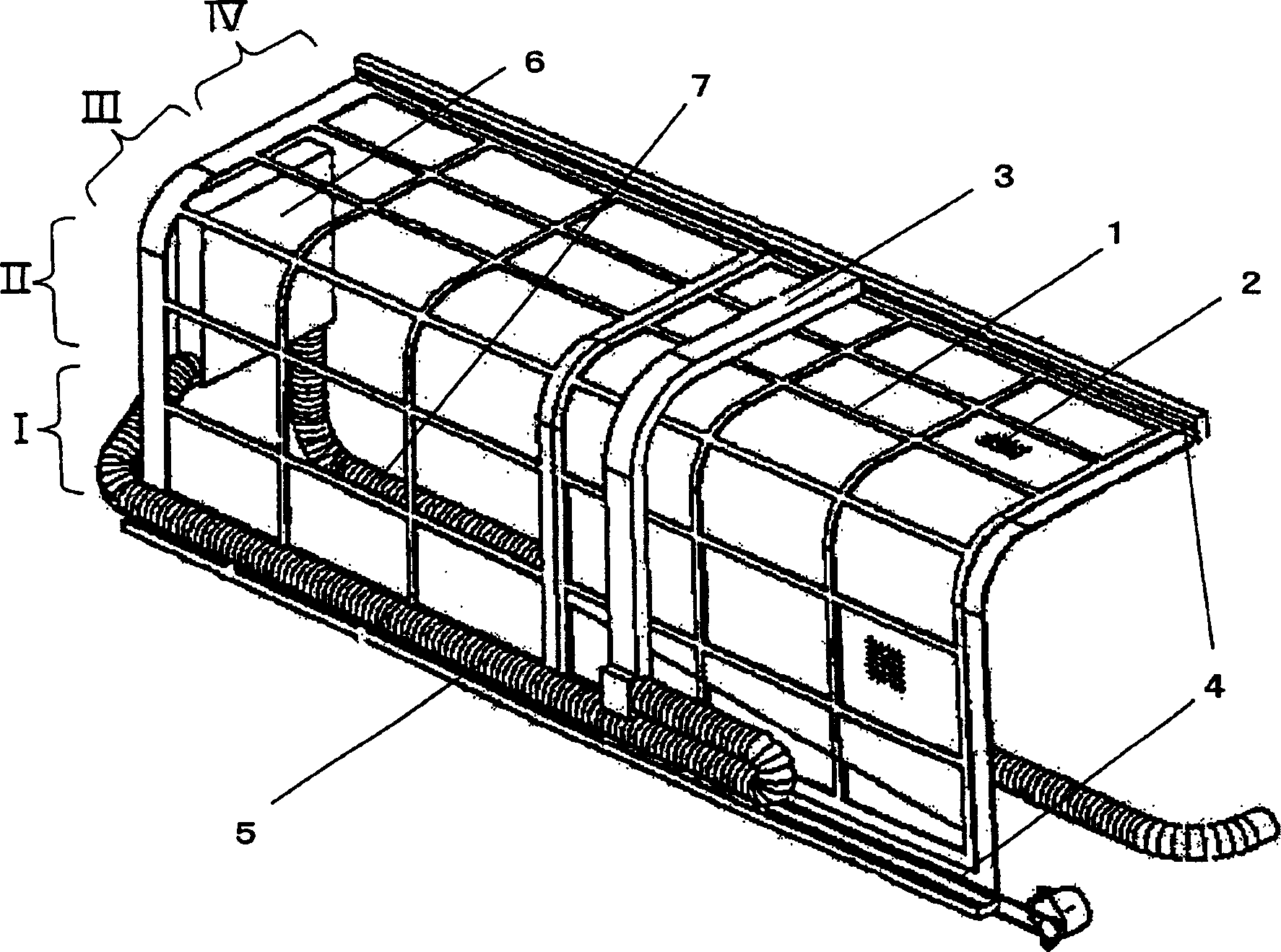

[0086] Figure 1 to Figure 8 The attachment part of the air filter provided in the indoor unit of the air conditioner related to Embodiment 1 of this invention is demonstrated in .

[0087] Such as figure 1 As shown, the air filter configured on the upstream side of the heat exchanger (not shown in the figure) and used to remove dust contained in the air flowing into the heat exchanger is composed of a filter frame 1 and a filter screen 2. A suction nozzle device 3 capable of moving along the surface of the air filter. The suction nozzle device 3 can move smoothly left and right while maintaining an extremely narrow gap with the air filter through the guide rails 4 provided at the upper and lower ends of the filter frame 1 . The dust attached to the air filter is sucked off by the suction nozzle device 3 .

[0088]One end (lower end) of the suction nozzle device 3 is connected with one end of the suction air duct 5 formed by a flexible excellent bellows hose etc. ) The suc...

Deformed example 1

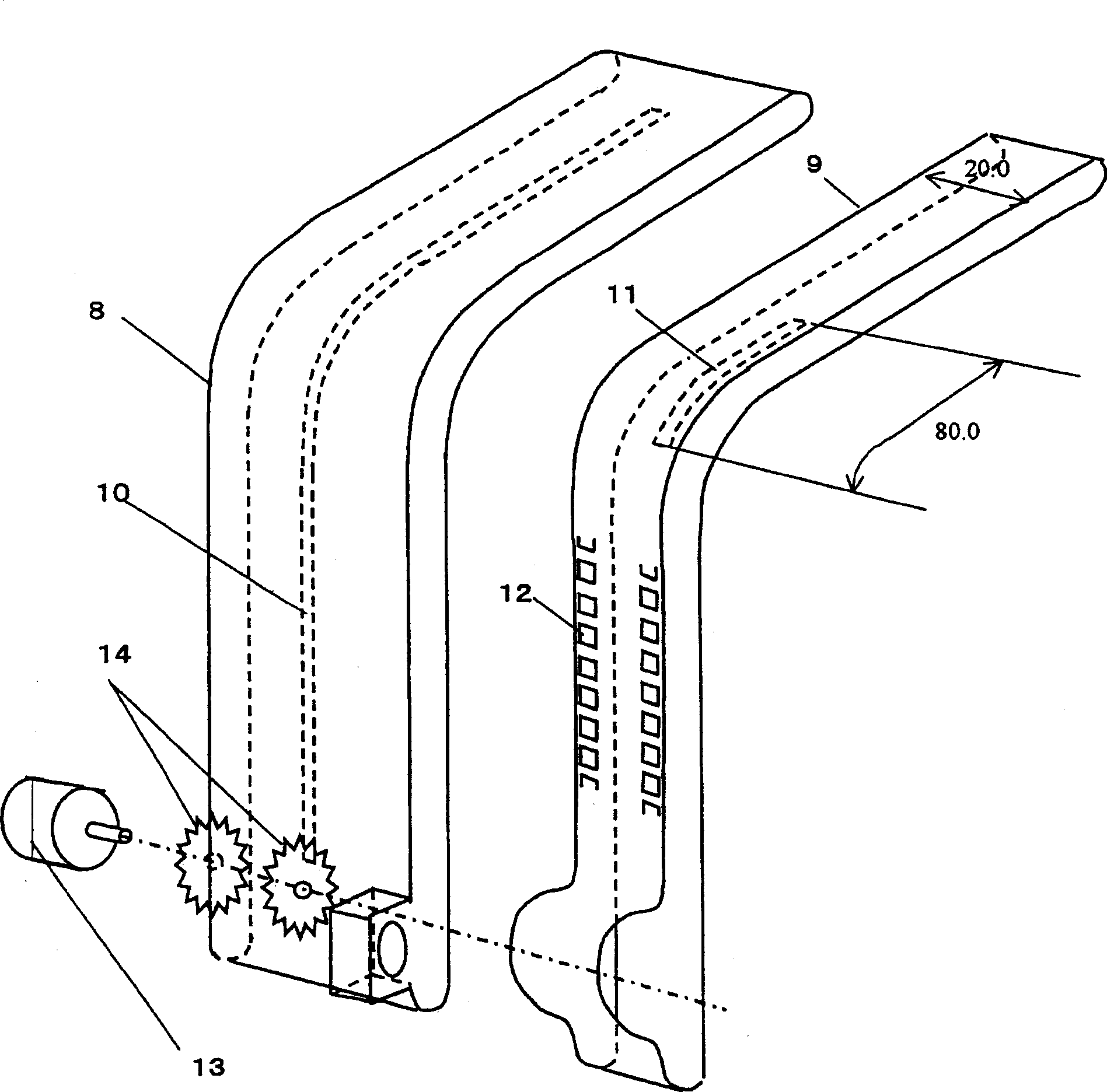

[0101] The thickness of suction belt 9 is preferably as thin as possible, by making suction belt 9 thinner can guarantee the softness of its curved part (especially the top end and the root of suction nozzle device 3), thereby can carry out suction smoothly. The driving action of the dust belt 9. In addition, by making the suction tape 9 thinner, the suction tape 9 other than the suction hole 11 is tightly attached to the nozzle opening 10 due to the suction force, thereby sealing, and suction leakage other than the suction hole 11 can be suppressed and suction leakage can be prevented. The resulting reduction of the suction force on the suction hole 11 . From above-mentioned aspect and aspects such as durability, strength, preferably use thin plastic film as dust-absorbing belt 9. However, in the case of using a thin suction belt, it may not be able to withstand the tension during driving due to the reduction in the strength of the suction belt. In this case, by making a pa...

Deformed example 2

[0104] On the basis of the shape of Modification 1, increasing the thickness of the dust-absorbing belt 9 around the suction hole 11 provided on the dust-absorbing belt 9 is also beneficial to improving the strength of the dust-absorbing belt 9 . As mentioned above, it is preferable to use a thin plastic film for the suction belt 9, and if a thin plastic film is used, the belt may not be able to withstand the tension during driving due to the reduced strength of the suction belt. In particular, the strength of the suction belt 9 in the part where the suction holes 11 are located is significantly reduced. In this case, by making the periphery of the suction hole 11 thick, the strength of the suction belt 9 at the portion where the suction hole 11 is located can be increased.

[0105] Figure 10 , shows a cross-sectional view of another modified example of the suction belt 9. By making the surrounding part of the suction hole 11 thick, for example, 0.2 mm, sufficient strength c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com