Juice extracting method and device for preparing pineapple fruit juice

A pineapple fruit and fruit juice technology, which is applied in the fields of juice extraction, food science, application, etc., can solve the problems of increasing equipment investment costs and low daily processing capacity of pineapple fruit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0017] The present invention will be described in further detail below in conjunction with the implementation and the accompanying drawings.

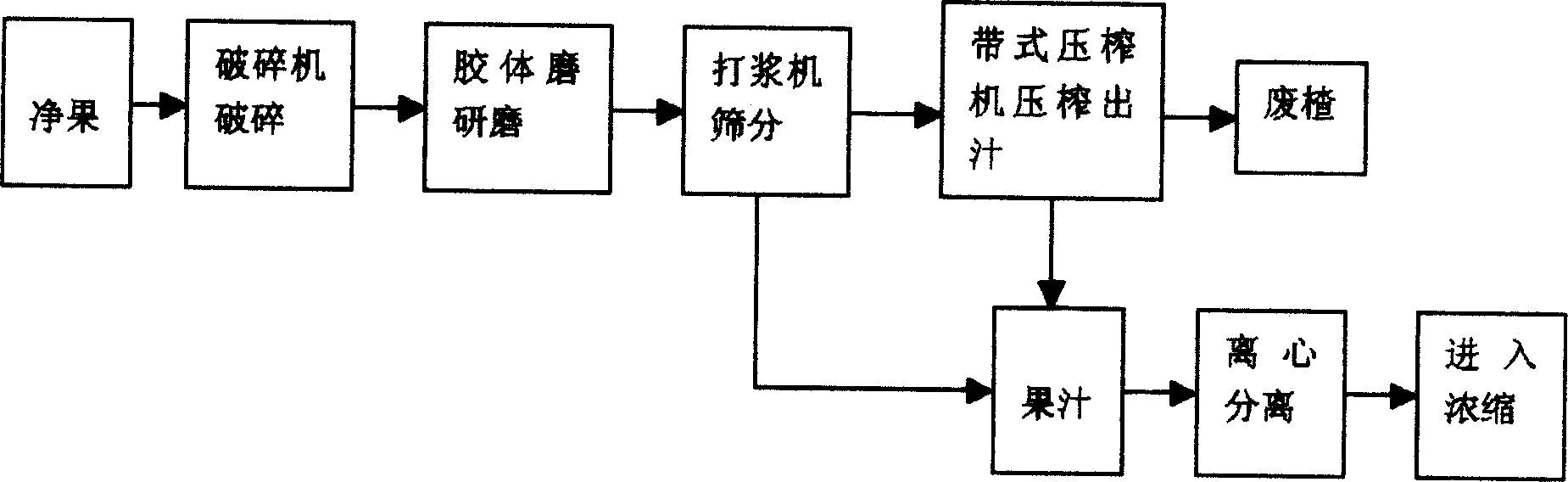

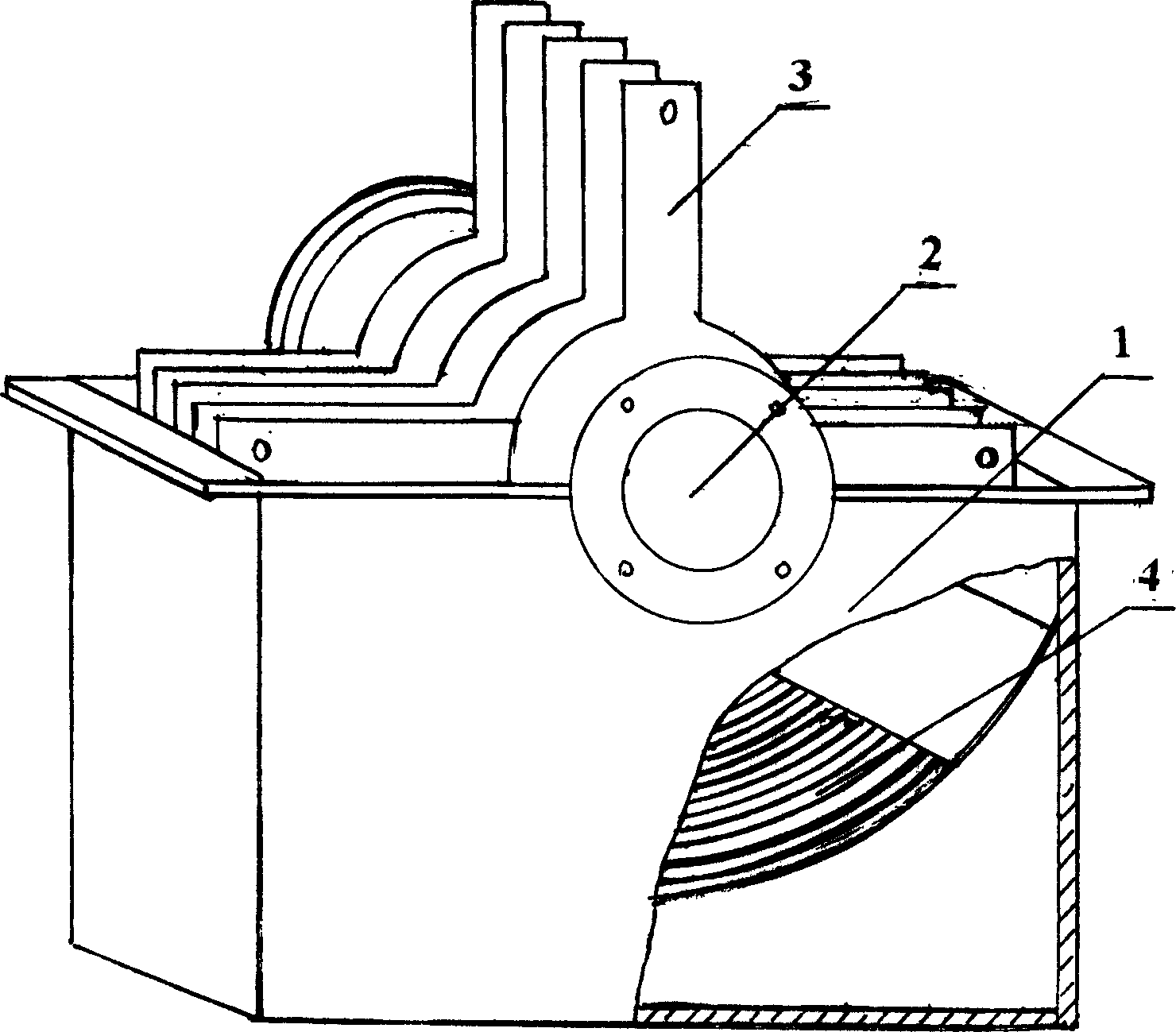

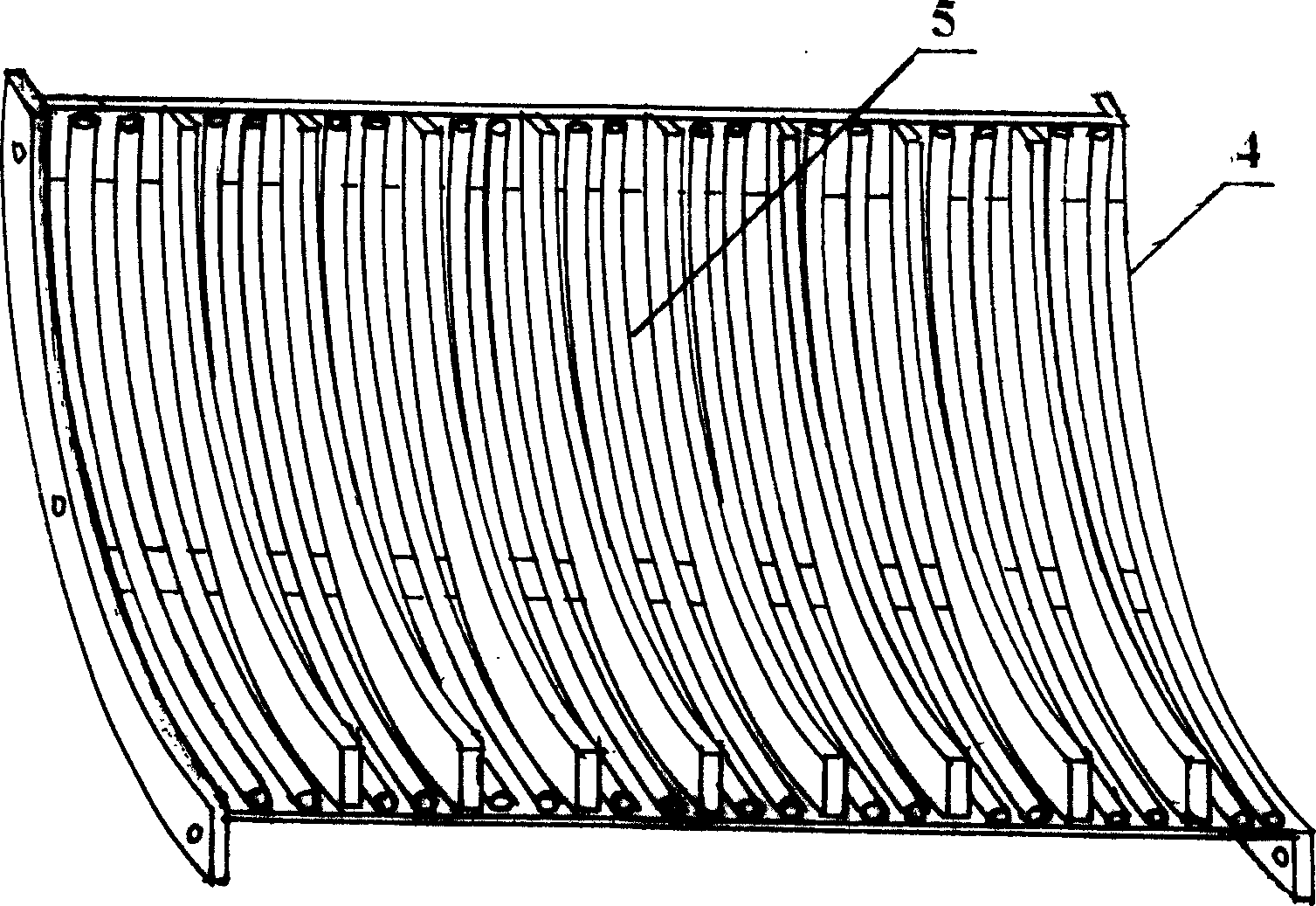

[0018] As above attached figure 1 As shown, the production method of the present invention includes several steps such as crushing the pulp, grinding the fruit grains through a colloid mill, screening the fruit grains through a beater, and pressing the fruit juice with a belt press. First, the freshly peeled pineapple fruit is crushed. The equipment used at this time is a pineapple fruit crusher, and the pineapple fruit crusher is as attached above figure 2 As shown, it is mainly composed of a chassis 1 and a main shaft 2. There are 16-24 hammers 3 installed on the main shaft 2. The hammers 3 are staggeredly installed on the main shaft 2. The thickness of each hammer 3 is 5-12 mm. The bottom of 2, the bottom of cabinet 1, screen cloth 4 is installed, and the shape of the sieve hole 5 of screen cloth 4 is strip shape as attached figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com