Blow moulded plastic bottle for hot filling

A technology of hot filling and plastic bottles, which is applied in the field of containers, can solve the problems of poor hand feeling, and achieve the effect of beautiful and novel appearance, preventing unreasonable deformation and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

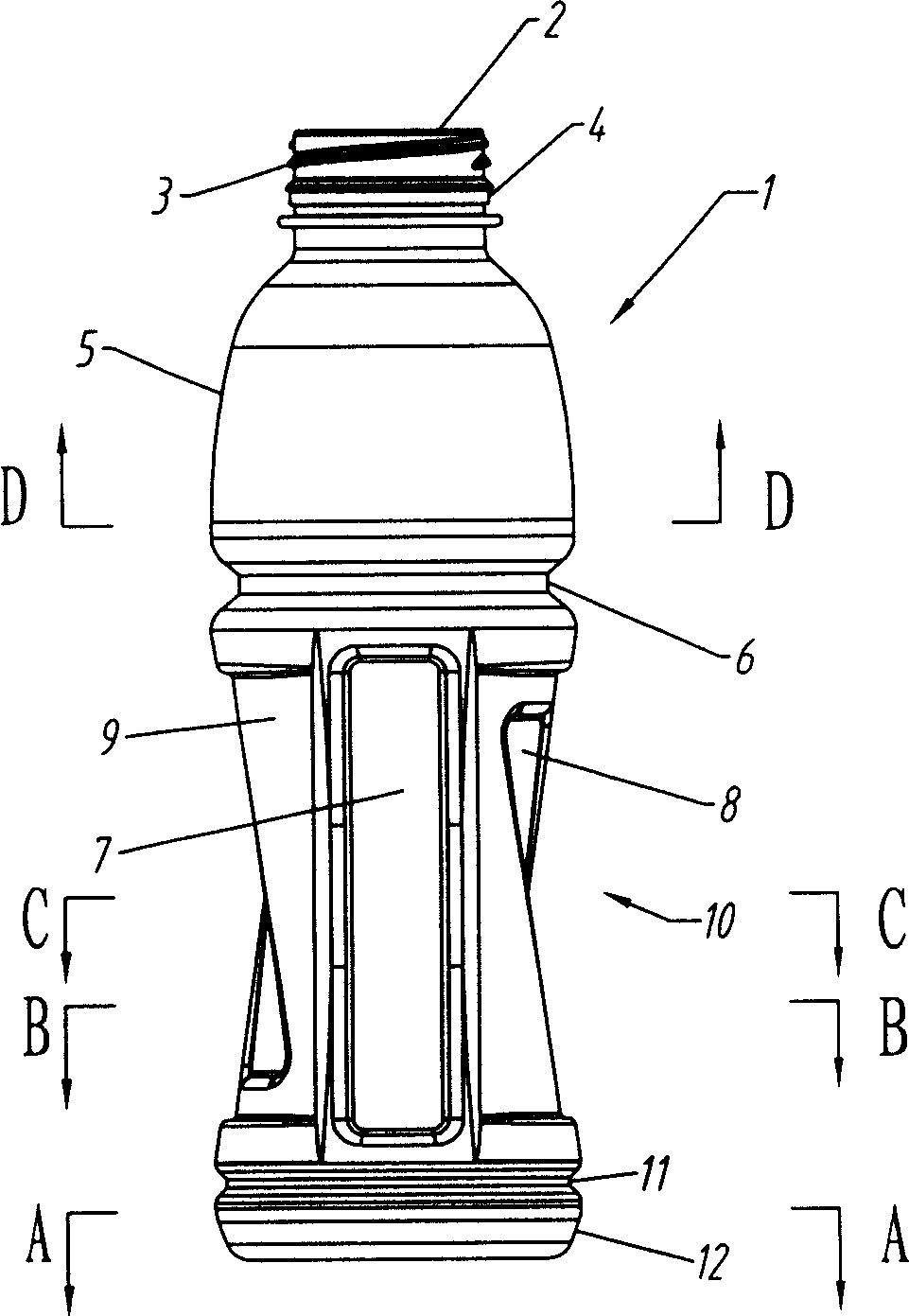

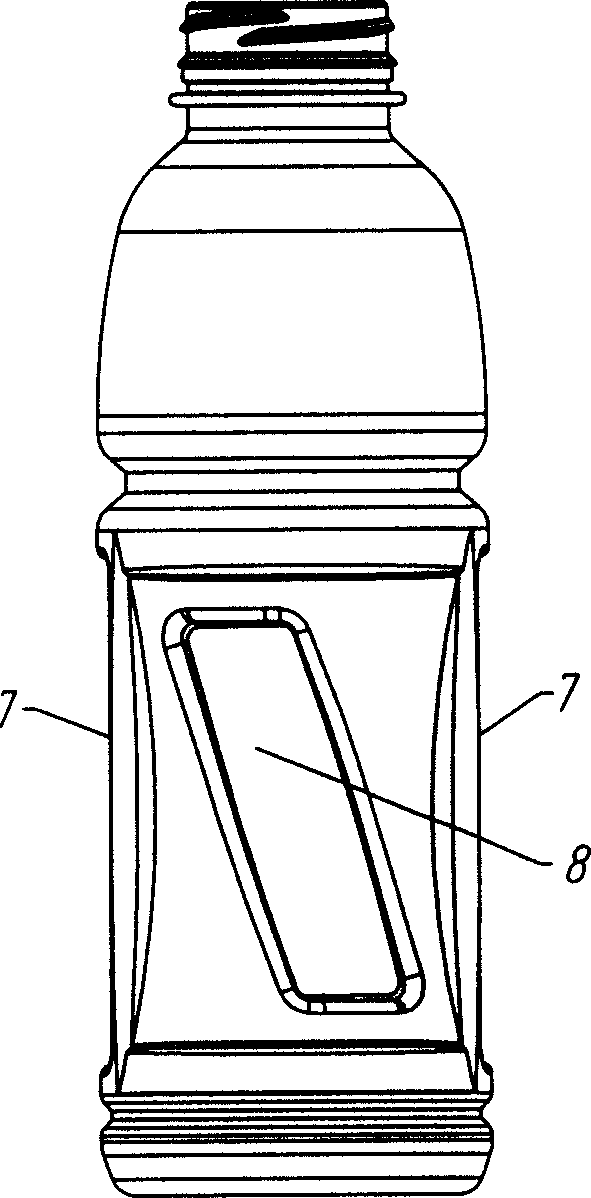

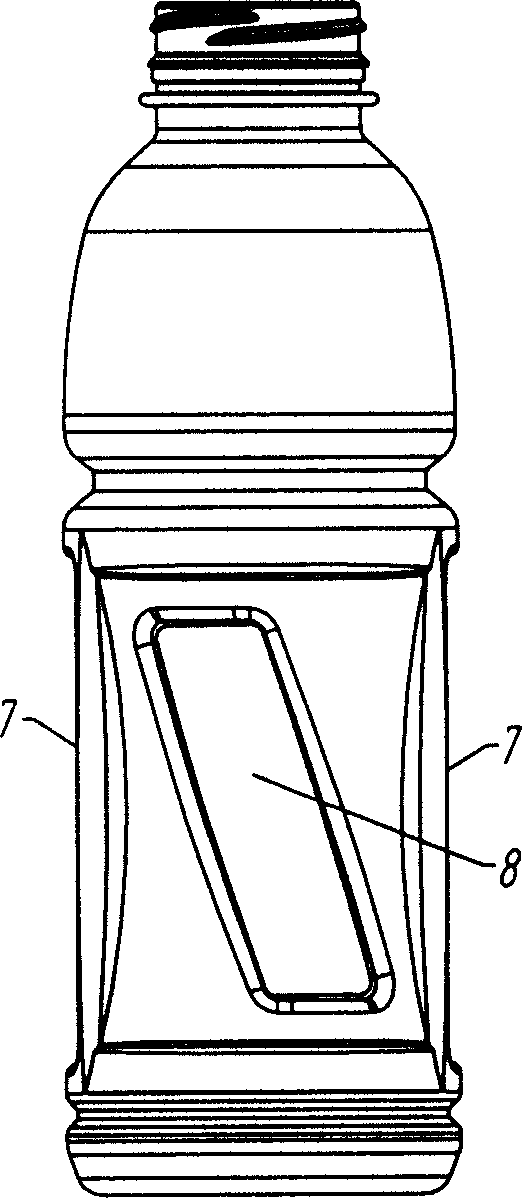

[0016] see Figure 1 ~ Figure 3 , bottle 1 comprises bottleneck 2, bottle shoulder 5, bottle body 10 and bottle bottom 12, and bottleneck 2 is made up of bottleneck 4 and the screw thread 3 that is positioned at bottleneck 4, and bottle shoulder 5 extends downwards from bottleneck 2 to bottle body 10 is connected, and the bottle body 10 is connected to the bottle bottom 12. The bottle body 10 includes two straight frames 7 and two slanted frames 8, the two straight frames 7 are perpendicular to the horizontal plane and are symmetrical to each other, and the two slanted frames 8 are inclined to the horizontal plane. And the angles of inclination of the two swash plate frames 8 are the same, and the inclination directions are opposite, and a side plate 9 is connected between the straight plate frame 7 and the slant plate frame 8; a groove 6 is arranged between the bottle shoulder 5 and the bottle body 10, and the bottle body 10 is connected to A groove 11 is arranged between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com