Double blanking tubular storehouse

A double-feeding, cylindrical technology, which is applied in the field of conveying devices and solid bulk storage, can solve the problem that the feeding port is easy to be blocked, the feeding port cannot control and adjust the loading and unloading of powder, and the discharge pipe system cannot meet the simultaneous It can achieve the effect of high reliability and flexible operation by solving the problems of material cutting or one transportation and one preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

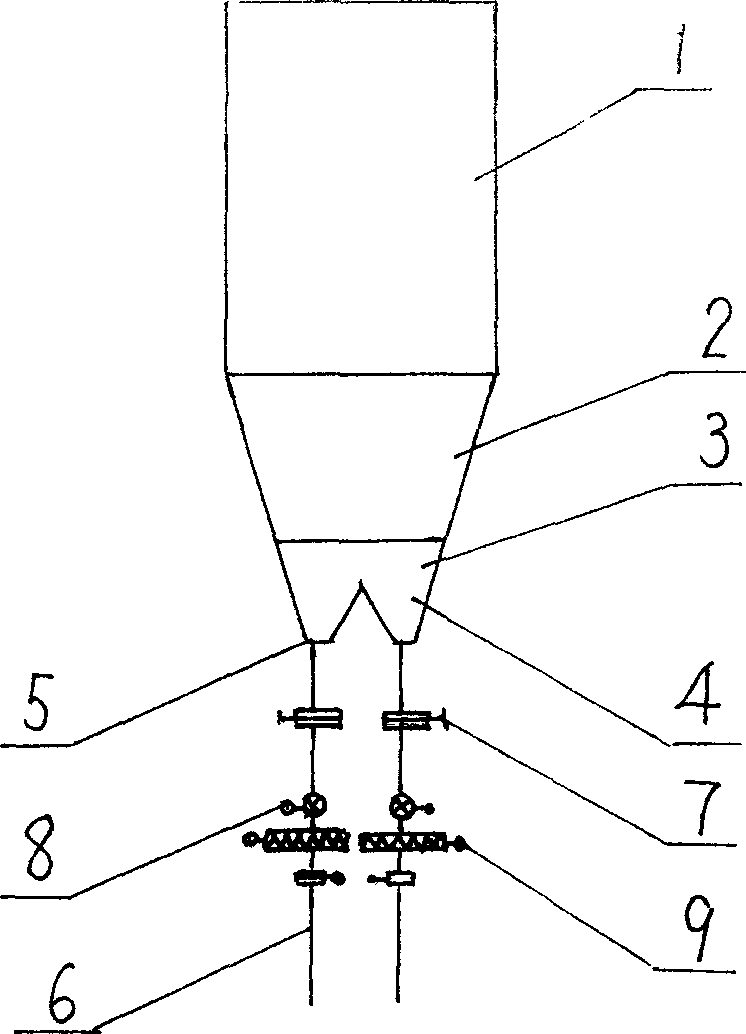

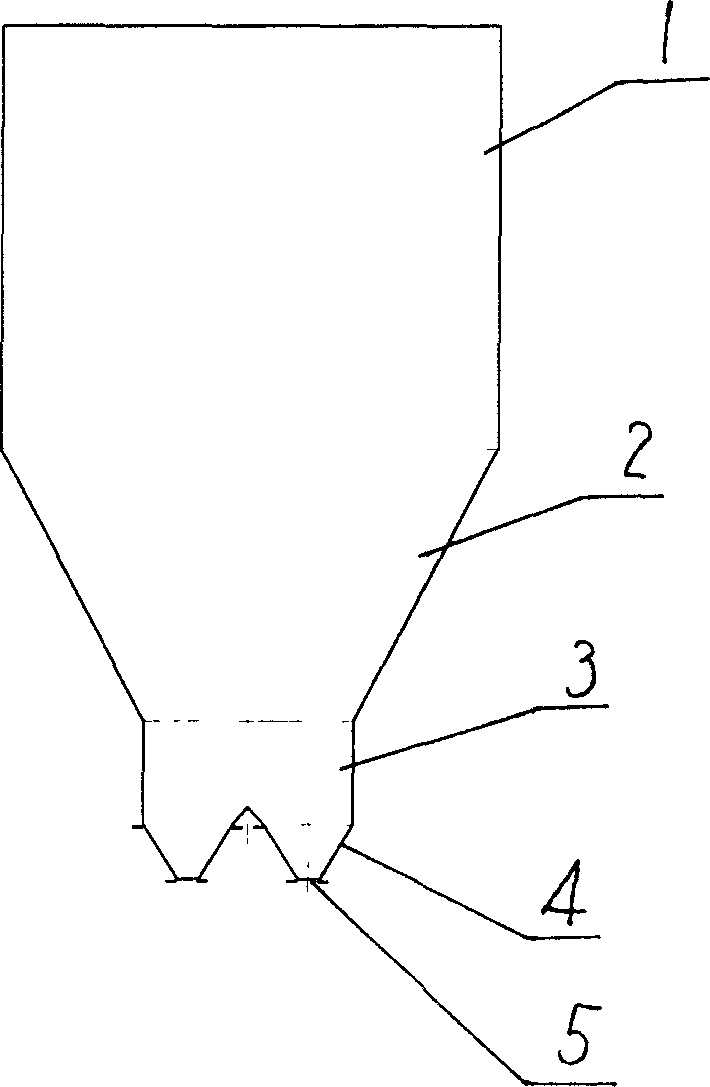

[0010] Embodiment one sees figure 1 , the upper section of the double-feeding cylindrical warehouse is cylindrical 1, the lower section is conical 2, the upper and lower sections are connected as one, and the bottom is opened with a discharge port, and the bottom of the conical section at the lower part of the cylindrical warehouse is connected to the pants-shaped double-feeding section 3 ,Such as figure 2 As shown, the upper part of the underpants-shaped double-cut section is cylindrical, and two small cones 4 are connected at the bottom of the cylinder. There are discharge ports 5 at the bottom of the two small cones, respectively, and the bottom of the discharge port is connected to the discharge port 5. The material pipeline 6 is provided with a flashboard shut-off door 7, an electric air locker 8, and a screw feeder 9 on the discharge pipeline.

[0011] In this example, the diameter of the steel circular silo is 9500mm, V=710m 3 The limestone powder silo is equipped wi...

Embodiment 2

[0012] Embodiment 2, on the discharge pipeline below the discharge port of the double-feeding barrel-shaped silo, the ram shut-off door and the electric air locker are arranged in sequence. The model of the electric air lock can be selected as 300×300 output 60t / h, and the groove width is 200.

Embodiment 3

[0013] Embodiment 3, on the discharge pipeline below the discharge port of the double-feeding barrel-shaped silo, the ram shut-off door and the electric screw feeder are arranged in sequence. The model of two screw feeders with frequency conversion speed regulation function can be selected as LS400 output 70t / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com