Dry spinning hot air circulation device

A technology of hot air circulation and dry spinning, which is applied in dry spinning, textile/flexible product manufacturing, and climate sustainability. Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

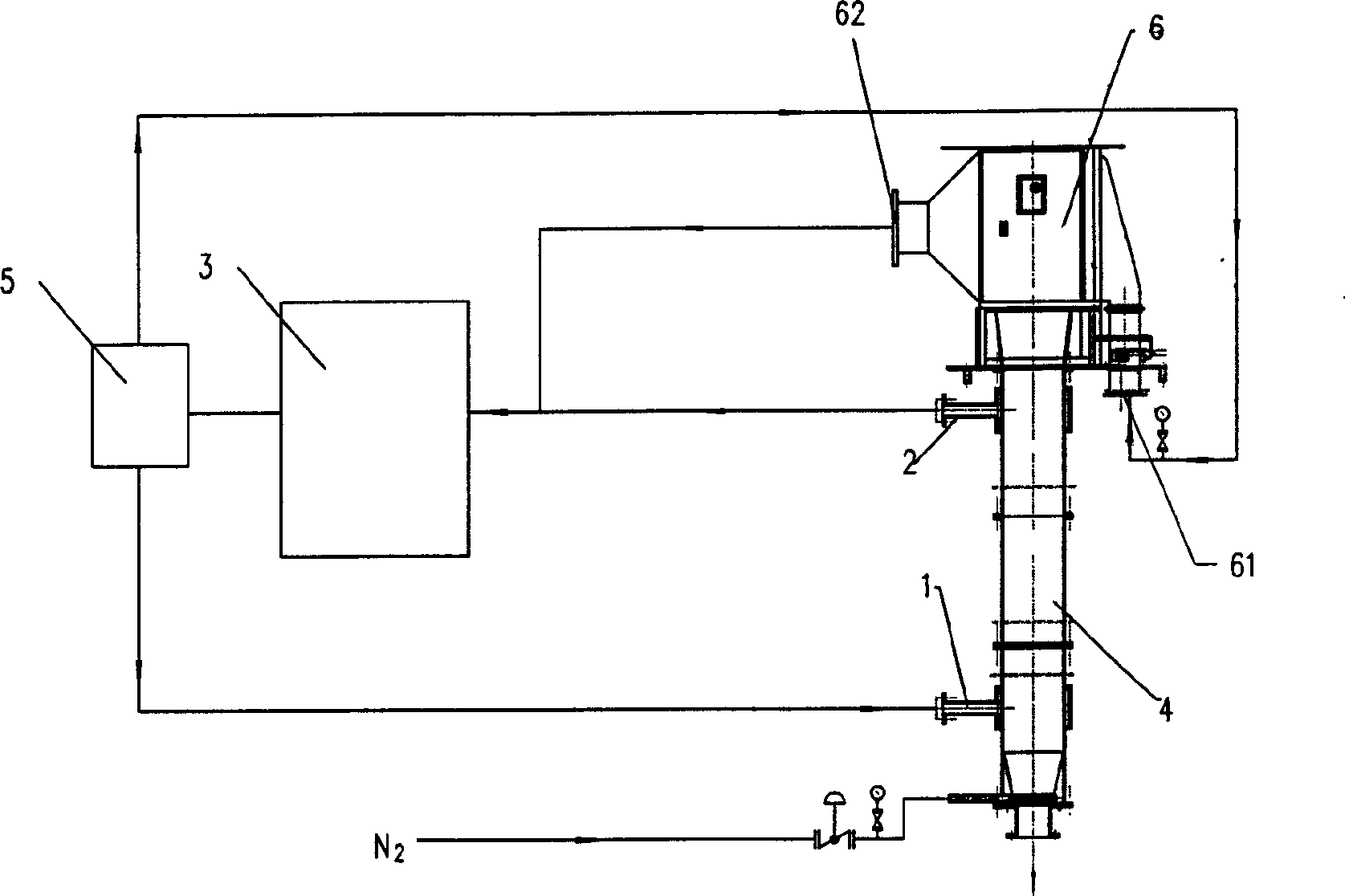

[0020] Embodiment one, see figure 1 , the figure shows a dry spinning hot air circulation device, which includes a tunnel 4, a solvent recovery device 3, and a heat exchanger 5. The tunnel 4 is respectively provided with a hot gas inlet 1 and an outlet 2, and the inlet 1 is located at the bottom of the tunnel 4. Below, the outlet 2 is located above the shaft 4; a side blowing device 6 is provided between the upper end of the shaft 4 and the spinneret, and two opposite sides of the side blowing device 6 have an inlet 61 and an outlet 62. The outlet of the solvent recovery device 3 is connected to the tunnel gas inlet 1 and the inlet 61 of the side blowing device through the heat exchanger 5, and the inlet of the solvent recovery device 3 is connected to the tunnel gas outlet 2 and the outlet 62 of the side blowing device.

[0021] Wherein the solvent recovery device 3 belongs to the prior art, and the gas that comes out through the gas outlet 2 of the tunnel 4 and the outlet 6...

Embodiment 2

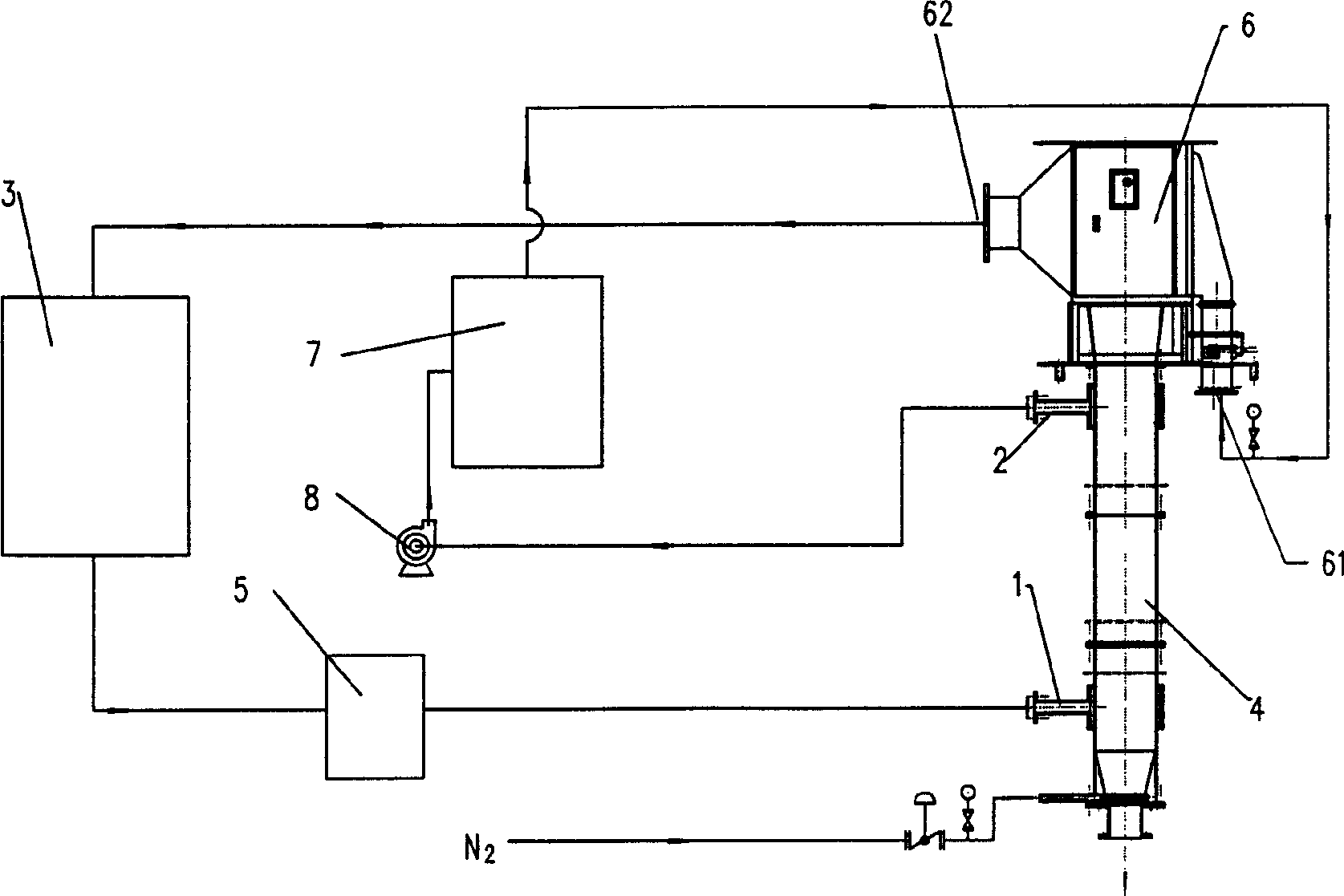

[0022] Embodiment two, see figure 2 , the figure shows a dry spinning hot air circulation device, including a tunnel 4, a solvent recovery device 3, and a heat exchanger 5. The tunnel 4 is respectively provided with a hot gas inlet 1 and an outlet 2, and the inlet 1 is located below the tunnel 4. , the outlet 2 is located above the shaft 4; at the outlet of the spinneret, the upper end of the shaft 4 is provided with a side blowing device 6, and the side blowing device 6 has an inlet 61 covering one side and an outlet 62 covering the other side and the outlet of the solvent recovery device 3 is connected to the tunnel gas inlet 1 through the heat exchanger 5, and the gas outlet 2 of the tunnel 4 is connected to the inlet 61 of the side blowing device; the inlet of the solvent recovery device 3 is connected to the outlet of the side blowing device 62 connected.

[0023] A heat exchanger 7 can be established between the entrance of the tunnel outlet 2 to the side blowing devic...

Embodiment 3

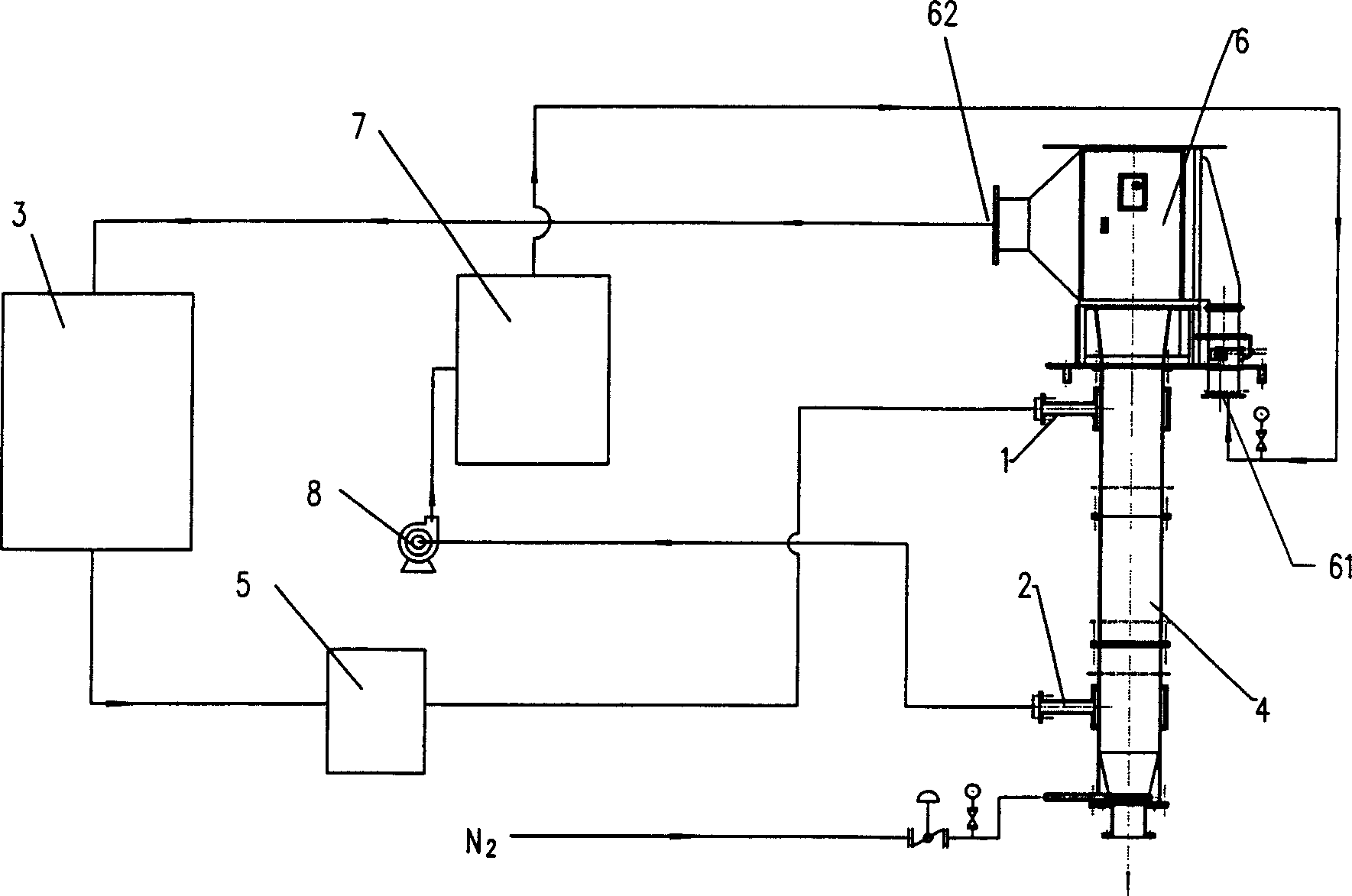

[0028] Embodiment three, see image 3 , the figure shows a dry spinning hot air circulation device, the difference from the previous embodiment is: the hot gas inlet 1 of the shaft 4 is located above the shaft 4, and the hot gas outlet 2 is located below the shaft 4. That is, the hot gas enters from the upper inlet 1 of the shaft 4, flows out from the outlet 2 below the shaft 4, and then is sent into the side blowing device 6. In this embodiment, the down-flow spinning and the side blowing device are combined in series Solvent evaporation and collection were performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com