Gas-insulated high-voltage switchgear

A high-voltage equipment and gas-insulated technology, which is applied in the installation of gas-insulated substations, electrical components, and busbars, can solve the problems of high manufacturing costs and high costs, and achieve sufficient mechanical properties, high mechanical strength, and good traceability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

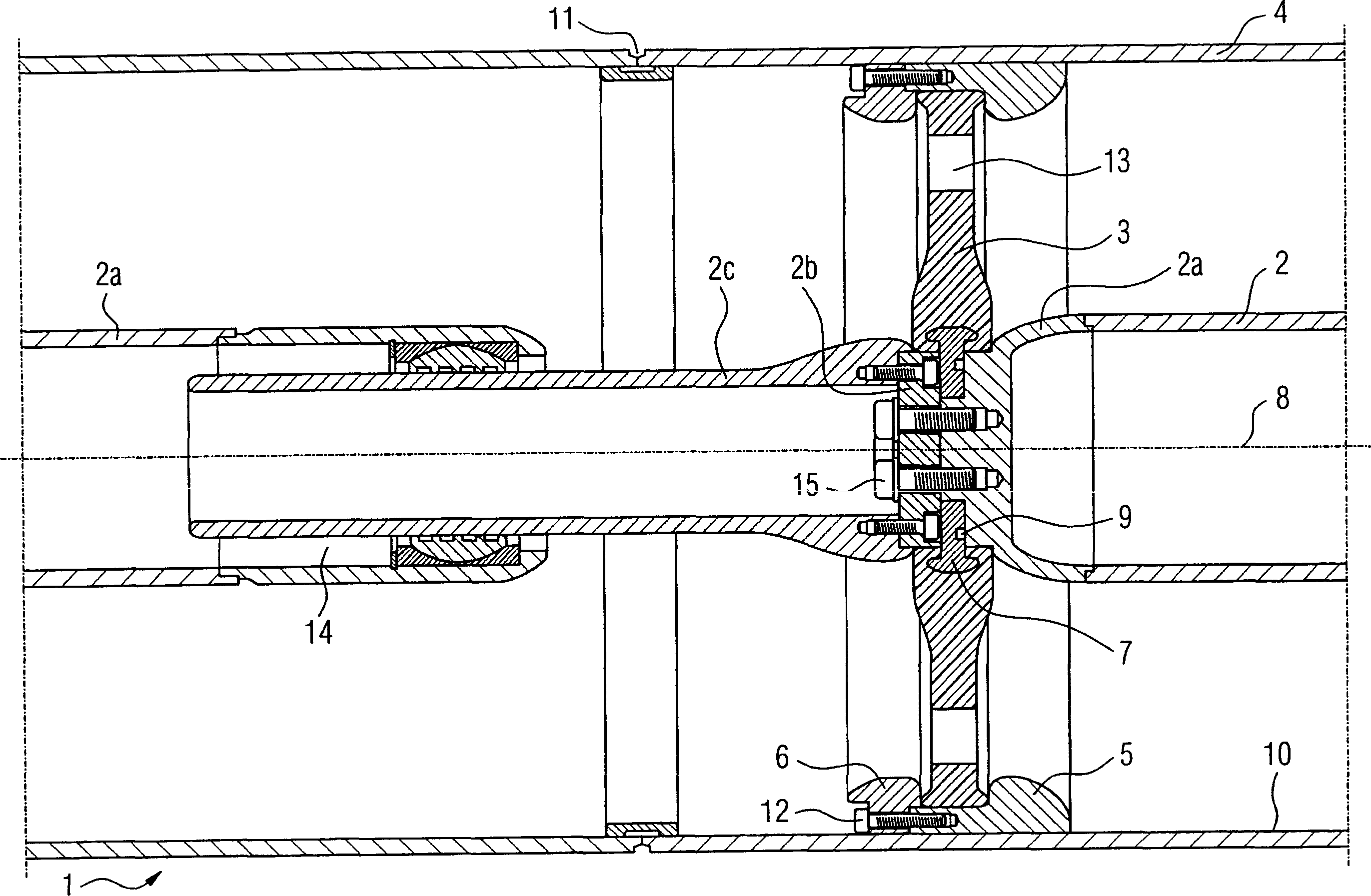

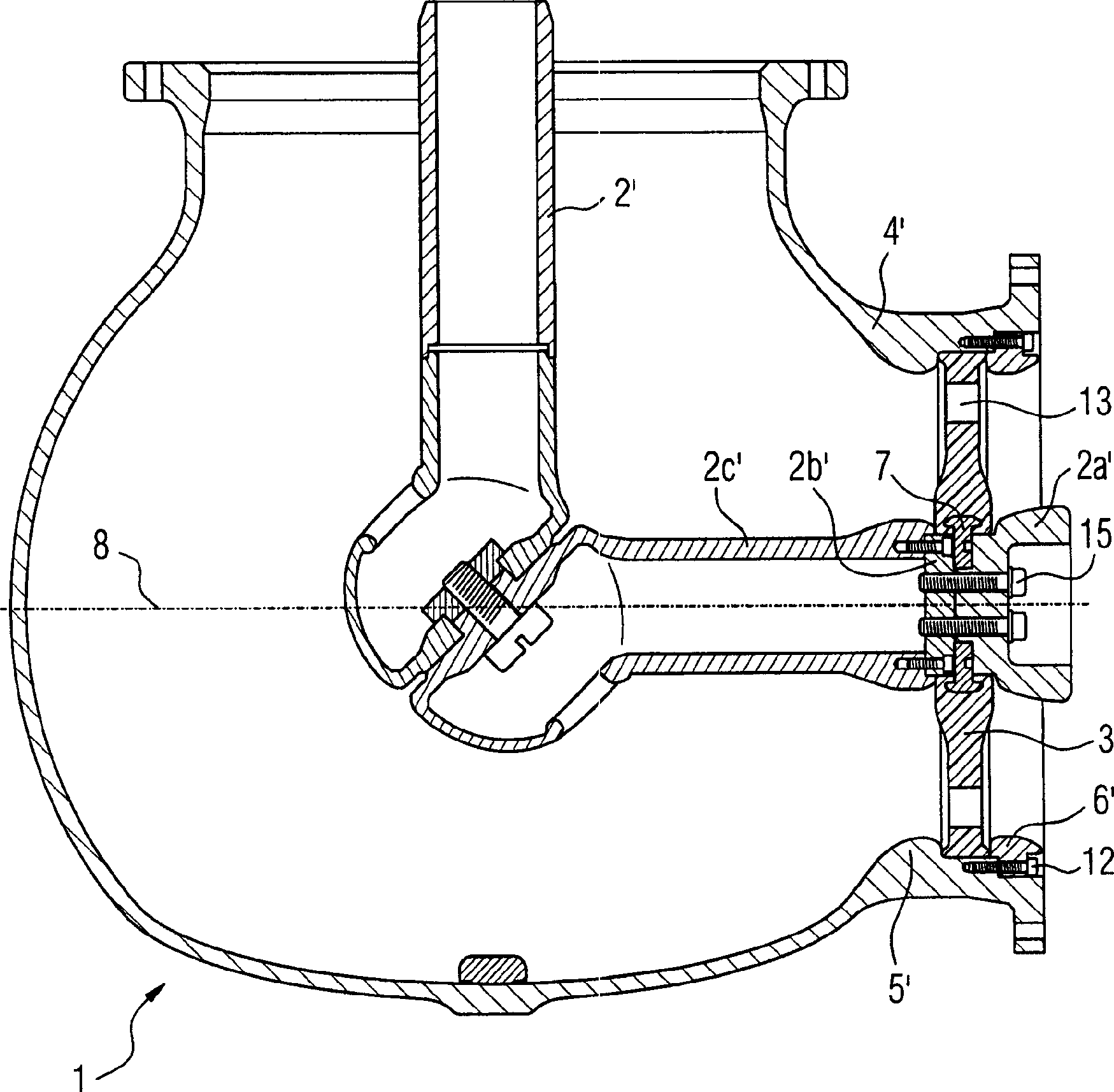

[0028] figure 1A gas-insulated high-voltage installation 1 according to the invention is shown. It is designed in particular for the transmission of high voltages in the range above 250 kV, ie the potential difference between a longitudinally extending inner conductor 2 and an outer conductor can exceed 245 kV in total. The inner conductor 2 is supported in the tubular outer conductor 4 by means of an insulator 3 , the insulator being fastened on the one hand to the inner conductor and on the other hand to the outer conductor by means of a first electrode 5 and a second electrode 6 . The outer conductor consists of tube modules. The pipe modules are joined to each other at the transfer point 11 . The tube is preferably made of aluminum (the inner conductor and all electrodes described here are also preferably made of aluminum unless otherwise stated).

[0029] Insulator 3 is designed as a flat disc, ideal situation is given in this example, that is, insulator 3 is substanti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com