Polishing, deburring and cleaning equipment

A technology for cleaning equipment and deburring, applied in the field of mechanical processing, to achieve the effects of less failure, high vibration characteristics, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

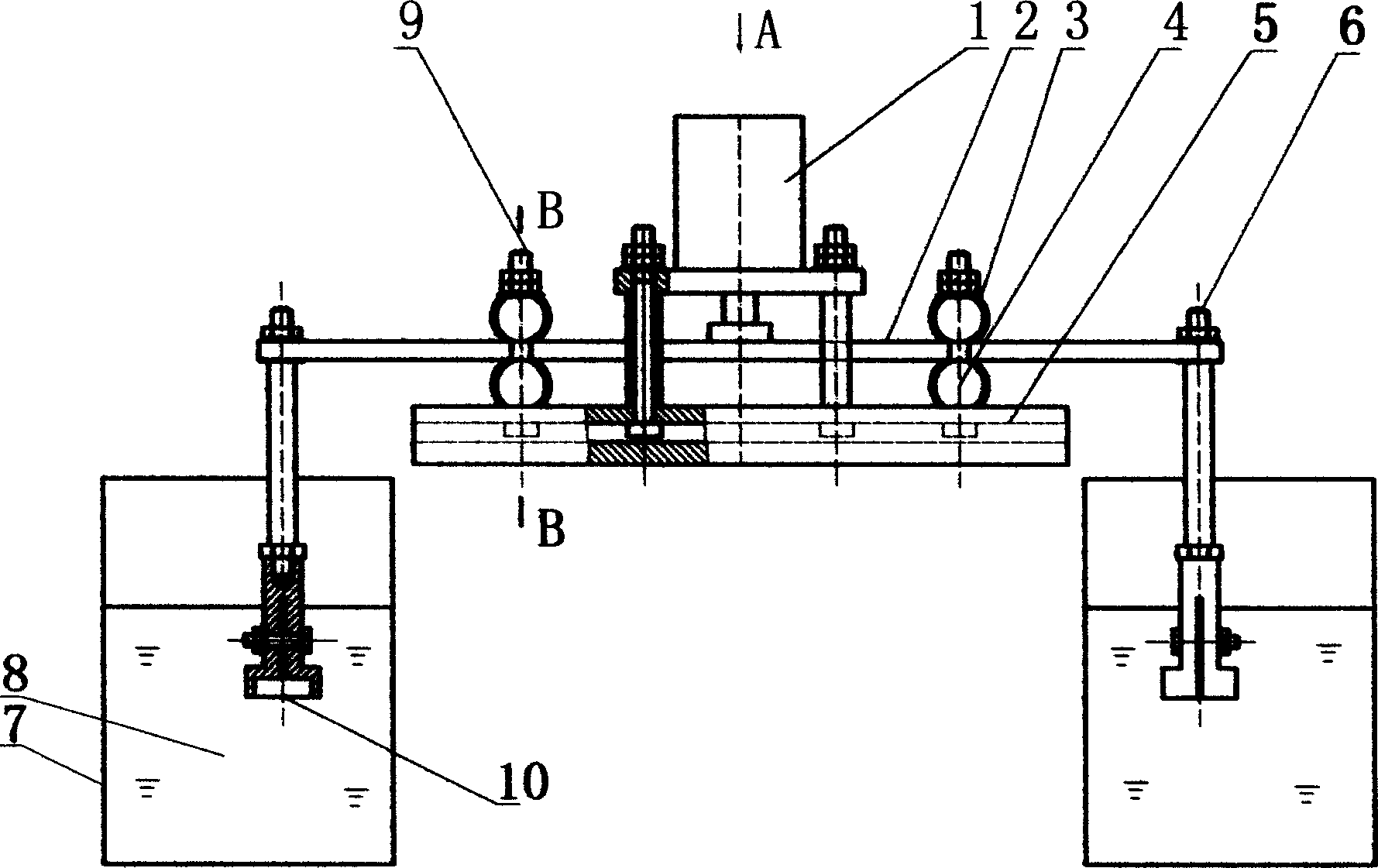

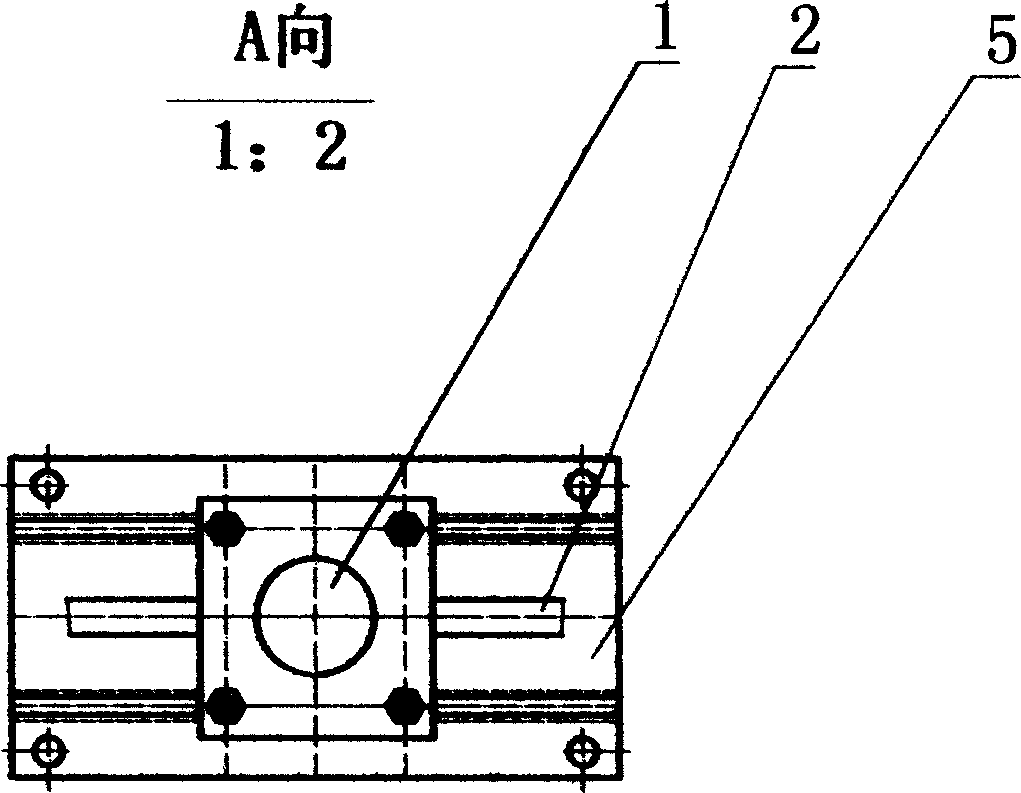

[0017] Embodiment 1: see specific structure figure 1 , mainly used for deburring after drilling and milling of certain round aluminum workpieces. There are 8 to 10 parts in each group, and the processing time is 3 to 7 minutes. The abrasive in the working fluid is micro-powder white corundum, all the burrs are removed, and the surface roughness is improved at the same time. Compared with the original manual deburring, the efficiency is increased by 2 to 5. times, and the processing quality is stable.

Embodiment 2

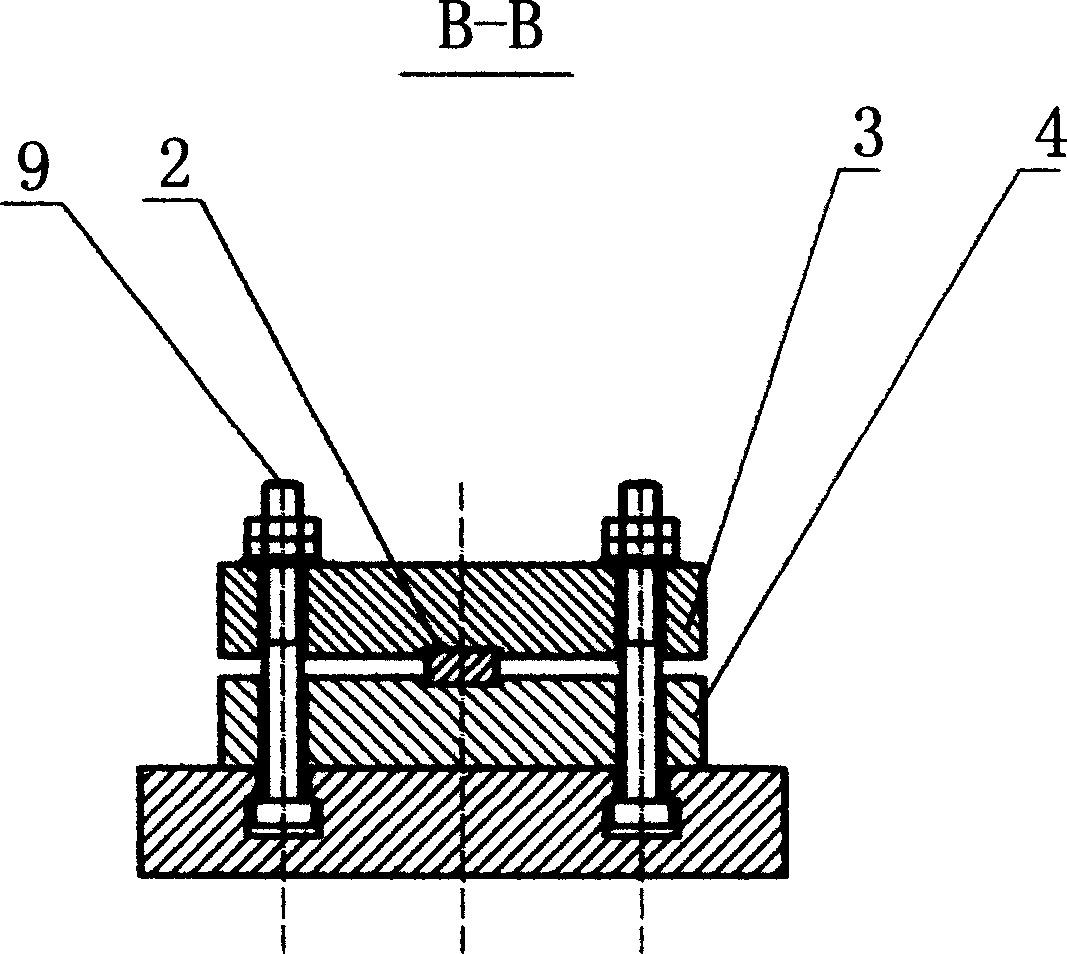

[0018] Embodiment 2: equipment structure such as figure 1 As shown, for the cleaning of a small part, there are several blind holes with a diameter of 1.2mm on the end face of the small part. Chips and oil stains stick to the bottom of the hole during processing of the part, and it is difficult to remove it manually. Adopt the present invention to clamp the workpiece, with the end facing down, and adjust the distance between the two supports on the vibrating steel beam 2 of the cylinder support. The working fluid is clear water plus ordinary cleaning agent, and a little silicone oil to eliminate foam. ~20 pieces, process for 1 minute, all chips are removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com