Technique for producing packing box adopting plan wrapping and backing-up and products therefrom

A packaging box and plane technology, which is applied in the directions of packaging, transportation and packaging, and box production operations, etc., can solve problems that affect production efficiency, cannot use plane methods, and are not beautiful, so as to improve labor efficiency and reduce physical exertion of employees.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

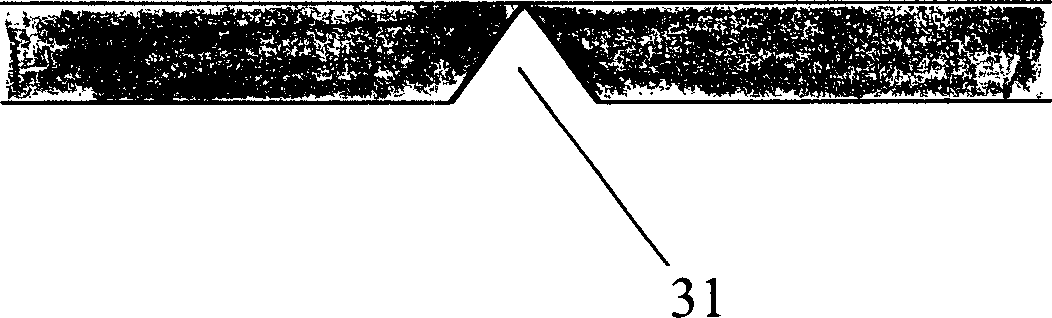

[0039] Choose corrugated cardboard as the raw material, and cut the cardboard according to the box type of the inner box of the book-shaped packaging box, such as Figure 6 As shown, it includes a side plate 11 and a bottom plate 21; then the outer surface of the cut cardboard is plane-mounted; after the wrapping, the paper fiber of the cardboard is cut off with a half-piercing knife (double knife) (half-piercing process) , form two parallel cut marks, the depth of the cut marks is about 0.3mm; then use a high-speed V-groove knife above 6000 rpm to excavate a V-shaped side plate cut groove 31 between the two parallel cut marks ( See image 3 ) and bottom plate groove 32.

[0040]Apply glue (adhesive) on the V-shaped grooves 31 and 32 excavated above, then bend inwards along the V-shaped grooves 31 and 32 to form Figure 4 As shown in the corner joint structure 4, the inner corner 5 of the corner joint 4 is basically a seamless structure, which does not need to be framed insi...

Embodiment 2

[0043] The inner box of the book-shaped packaging box is prepared in the same way as in Example 1, but the raw material used in the packaging box is low-density gray cardboard, and the depth of the parallel cuts is controlled to be 1 / 3 of the thickness of the cardboard during the preparation process, and The cut grooves excavated are as follows Figure 5 The V-shaped deformed groove shown;

Embodiment 3

[0045] Choose corrugated cardboard as the raw material, and cut the cardboard according to the box shape of the outer box of the book-shaped packaging box, such as Figure 8 As shown, it includes a bottom plate 22, a side plate 12 and a cover plate 72; the paper fiber of the cardboard is cut off (half pierced) with a half-piercing knife (double knife) to form two parallel cuts, the depth of which is about 0.5mm; and then use a high-speed V-groove knife above 6000 rpm to excavate a V-shaped groove 13 between the two parallel cuts; then carry out plane-mounting on the outer surface of the grooved cardboard.

[0046] The bottom plate of the inner box prepared in Example 1 is bonded on the bottom plate 22 of the outer box; then it is bent inwardly along the V-shaped groove 13 to form a Figure 9 Book-style box shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com