Antitheft well head assembly

A wellhead device and well grate technology, applied in water supply devices, waterway systems, drainage structures, etc., can solve problems such as poor impact resistance, vehicle jumping and noise, fatal accidents, etc., to improve corrosion resistance and impact resistance, Significant economic benefits and the effect of avoiding serious accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

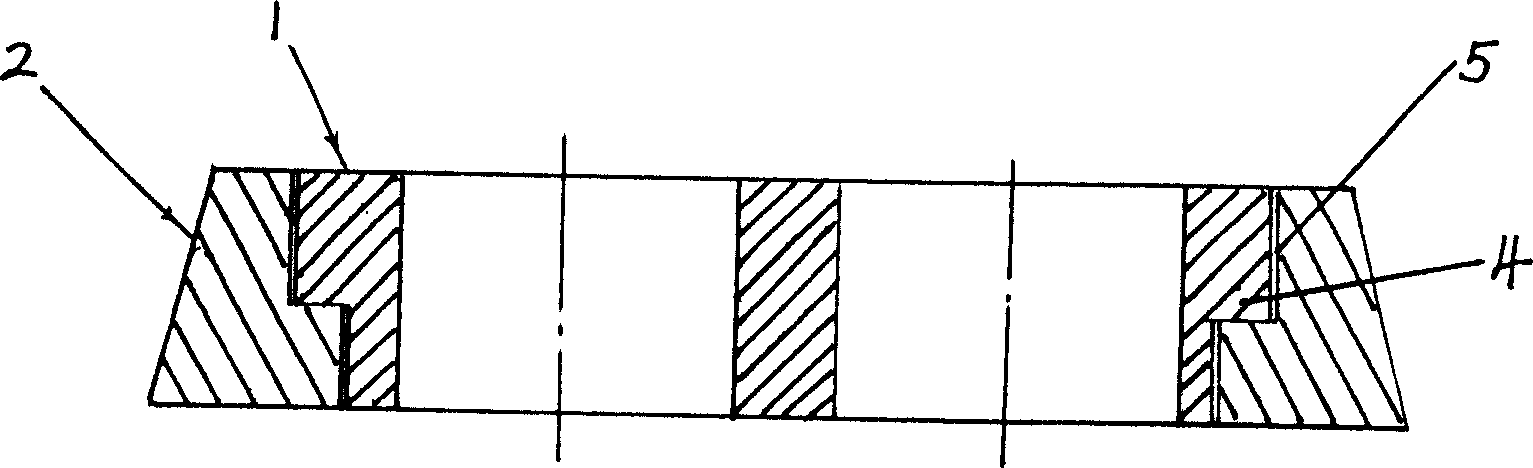

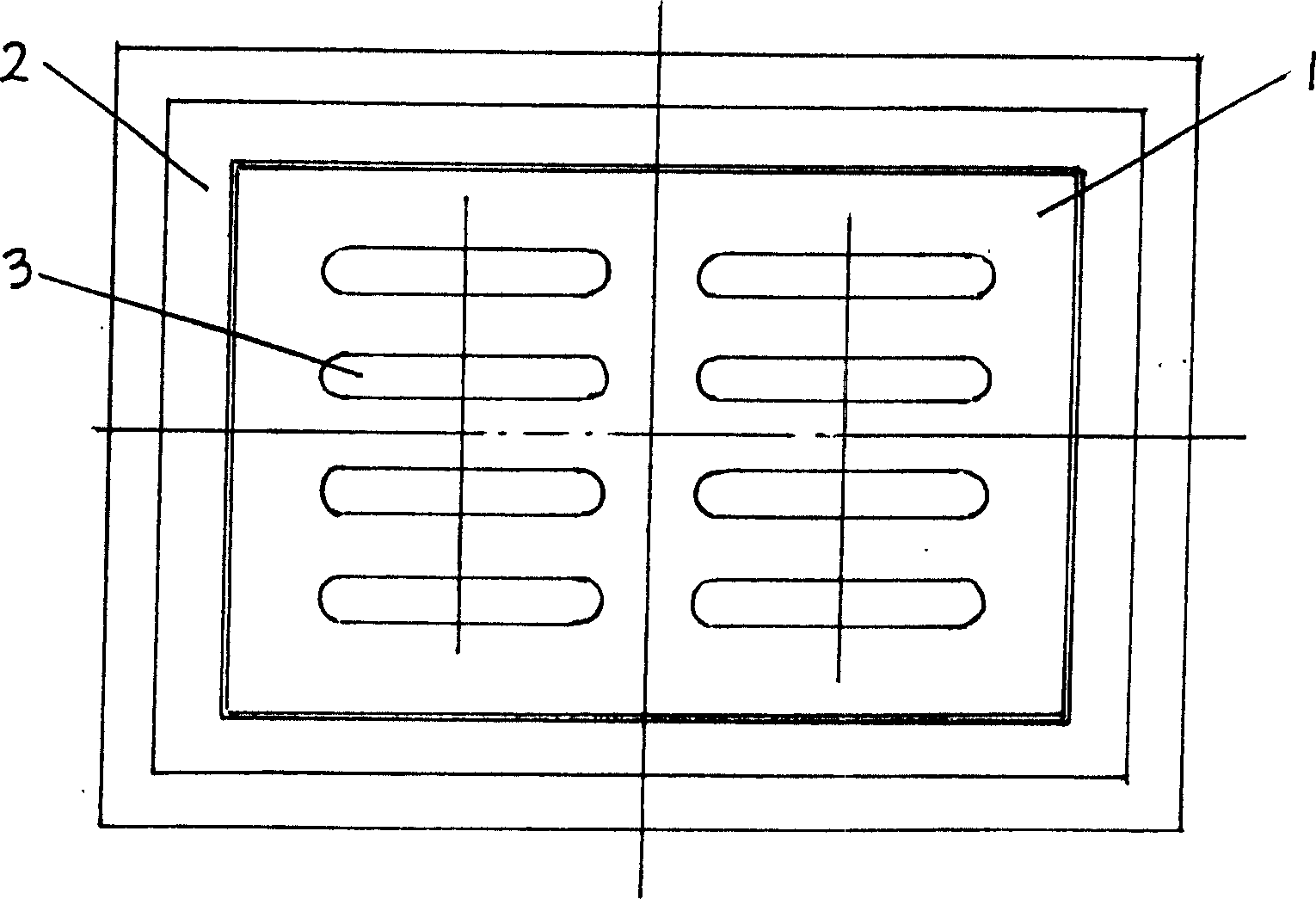

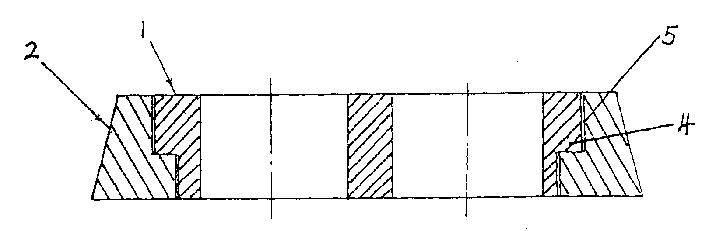

[0010] The anti-theft wellhead device includes a plastic well grate 1 and a plastic well base 2. There are a plurality of elongated through holes 3 on the plastic well grate 1. The upper end edge of the plastic well grate 1 protrudes outward and is provided with an annular boss 4. The plastic well grate The upper end of the inner wall of the seat 2 is concavely provided with an annular groove 5 adapted to the shape of the annular boss 4 at the upper end of the plastic well grate 1, and the plastic well grate 1 can be inserted in the plastic well seat 2, and the upper end of the plastic well grate The annular boss 4 just falls into the annular groove 5 on the upper end of the plastic well base 2 .

[0011] The plastic well grate and the plastic well seat are respectively made of 50% of fly ash, 20% of waste plastic, 20% of waste rubber, and 10% of synthetic resin. After mixing, stirring, extrusion, heat sealing, and mixing, they are molded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com