Intensified heat-exchange device for heat-exchanger

A technology to enhance heat exchange and heat exchanger, which is applied in the field of enhanced heat exchange devices for heat exchangers, checker bricks, and tubular heat exchangers. problems, achieve the effects of reducing energy consumption, increasing blast furnace air temperature, and enhancing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

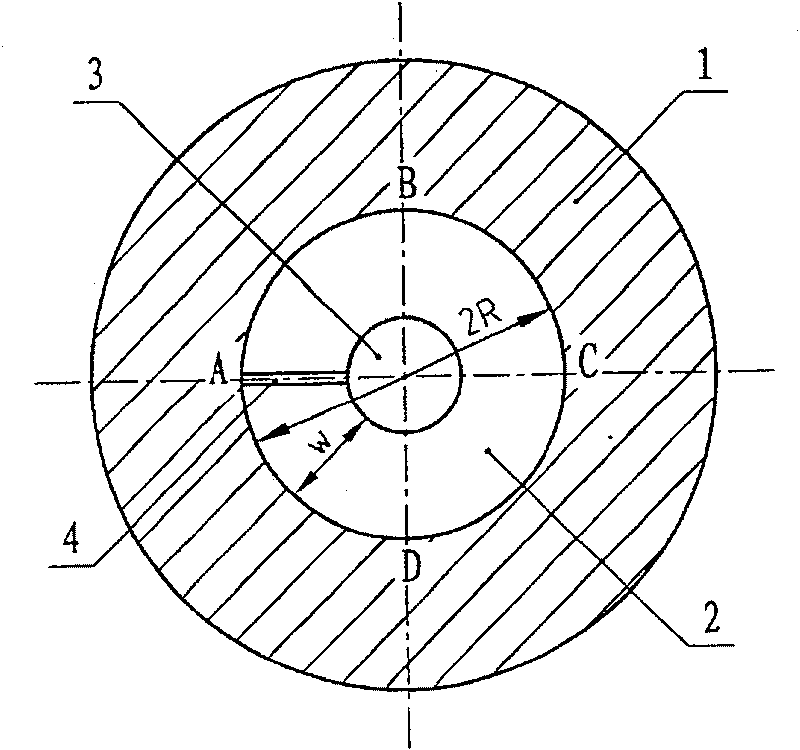

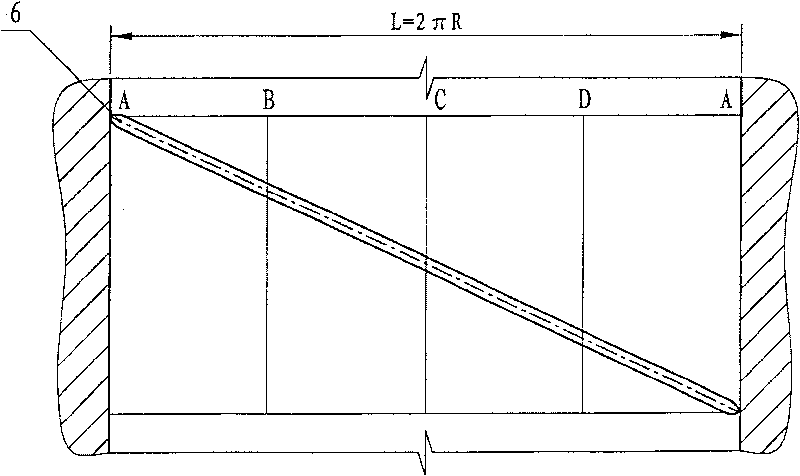

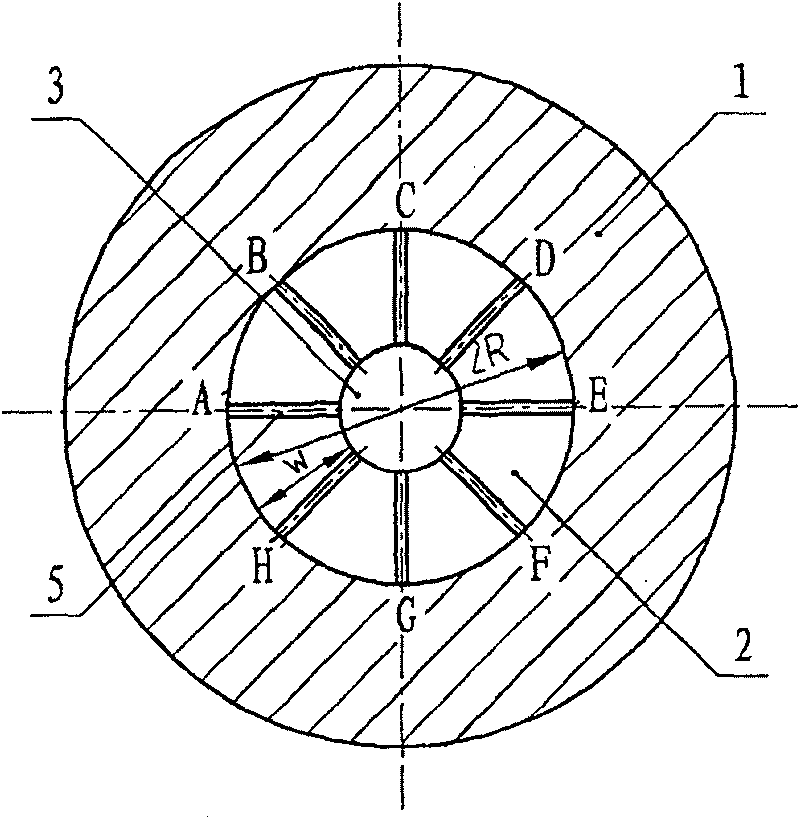

[0015] A heat exchanger strengthening heat exchange device of the present invention, in the selection of various parameters in practical application, it is necessary to consider that the heat exchange efficiency of the heat exchanger can be significantly improved, and the increase of its resistance is within the allowable range, and at the same time There are also many factors such as ease of production. For the metal steel pipe heat exchanger that uses the exhaust gas from the hot blast stove to preheat the gas and combustion-supporting air, and the checker bricks in the regenerator of the hot blast stove made of refractory materials, its parameters should be at a rotation angle α of 30°-50°. The number of blades of each blade type swirl device is 4-6, the pitch is 24R-36R and the blade width W is selected within the range of 0.4R-0.6R.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com