Circuit breaker

A circuit breaker and dynamic contact technology, which is applied in the direction of circuit breaker parts, circuit breaker contacts, circuits, etc., can solve the problems of decreased circuit breaker characteristics, decreased circuit breaker performance, difficulties, etc., and achieves suppression of contact pressure, high circuit breaker performance, and structure brief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

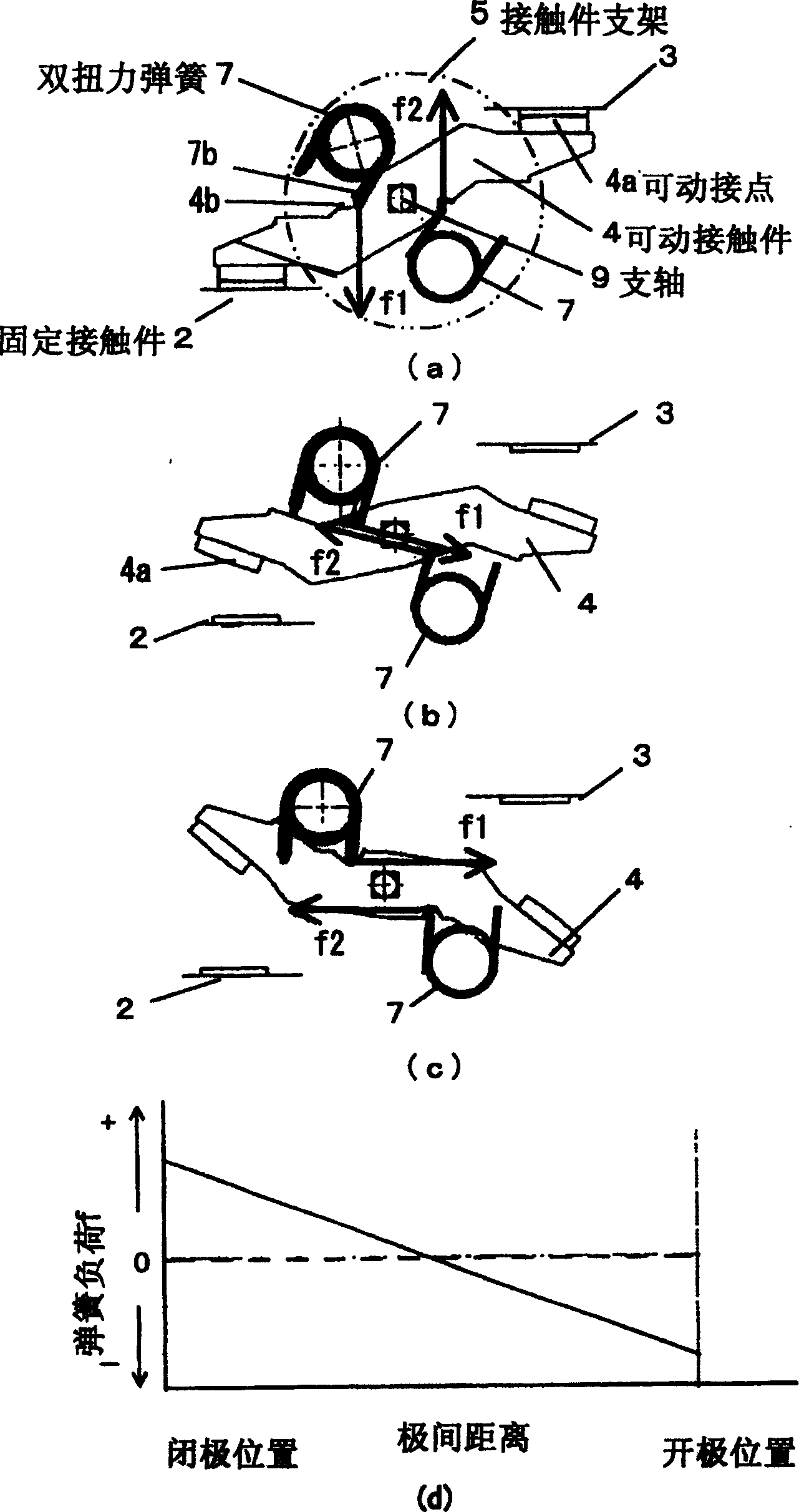

[0038] figure 1 (a) to (d) show examples corresponding to two aspects of the present invention. In this embodiment, although the current breaking part is basically the same as the structure of FIG. 5, as the contact pressure spring of the movable contact 4, two sets of double torsion springs 7 equipped on the contact holder 5 are arranged as follows . That is, the double torsion springs 7 arranged above and below the movable contact 4 are arranged to be axially symmetrical with respect to the support shaft 9 provided at the rotation center of the movable contact 4, and the double torsion springs 7 are displaced from the double torsion The displacement arm portion 7b protruding from the center of the spring 7 is shorter than the structure shown in FIG.

[0039] With this structure, in figure 1 In the closed pole position of (a), the spring loads f1 and f2 of the double torsion spring 7 work on the movable contact piece 4 as a force couple, and press the movable contact pie...

Embodiment 2

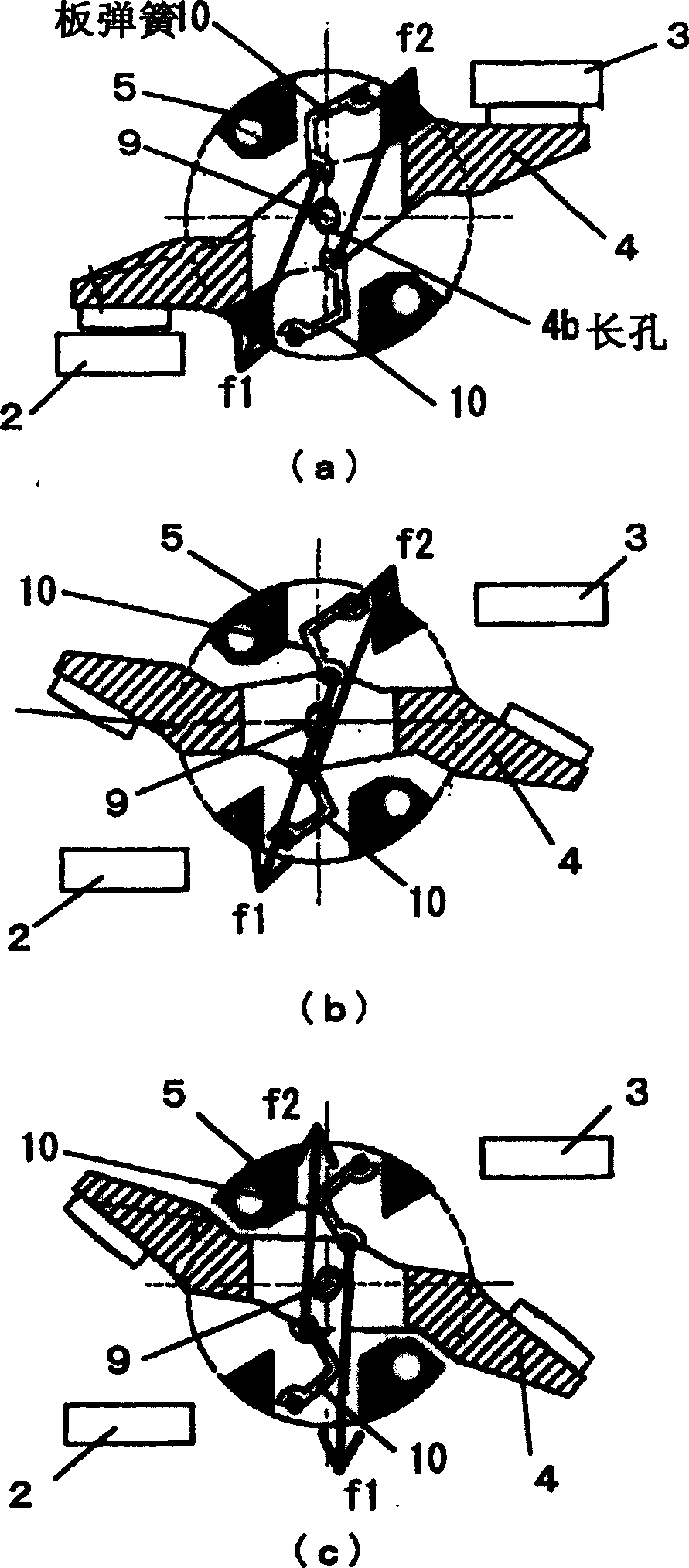

[0043] Then the embodiments corresponding to the 3rd and 4th aspects of the present invention are as follows figure 2 (a) ~ (c) shown. In this embodiment, the double torsion spring 7 of the foregoing embodiment 1 is replaced with a leaf spring 10 with a simple structure, and two sets of leaf springs 10 are mounted on the movable contact piece 4 in a deflected state as shown in the figure. Between the back of the upper and lower sides and the contact bracket 5, in figure 2 In the closed position of (a), the contact of the movable contact 4 is pushed toward the fixed contact by the spring loads f1 and f2 of the plate spring 10 . In addition, although a shaft hole passing through the support shaft 9 is opened at the rotation center of the movable contact 4, the shaft hole is formed along a line connecting the engagement points of the two sets of leaf springs 10 and the movable contact 4. The long hole 4b.

[0044] With this structure, if the electromagnetic repulsion force g...

Embodiment 3

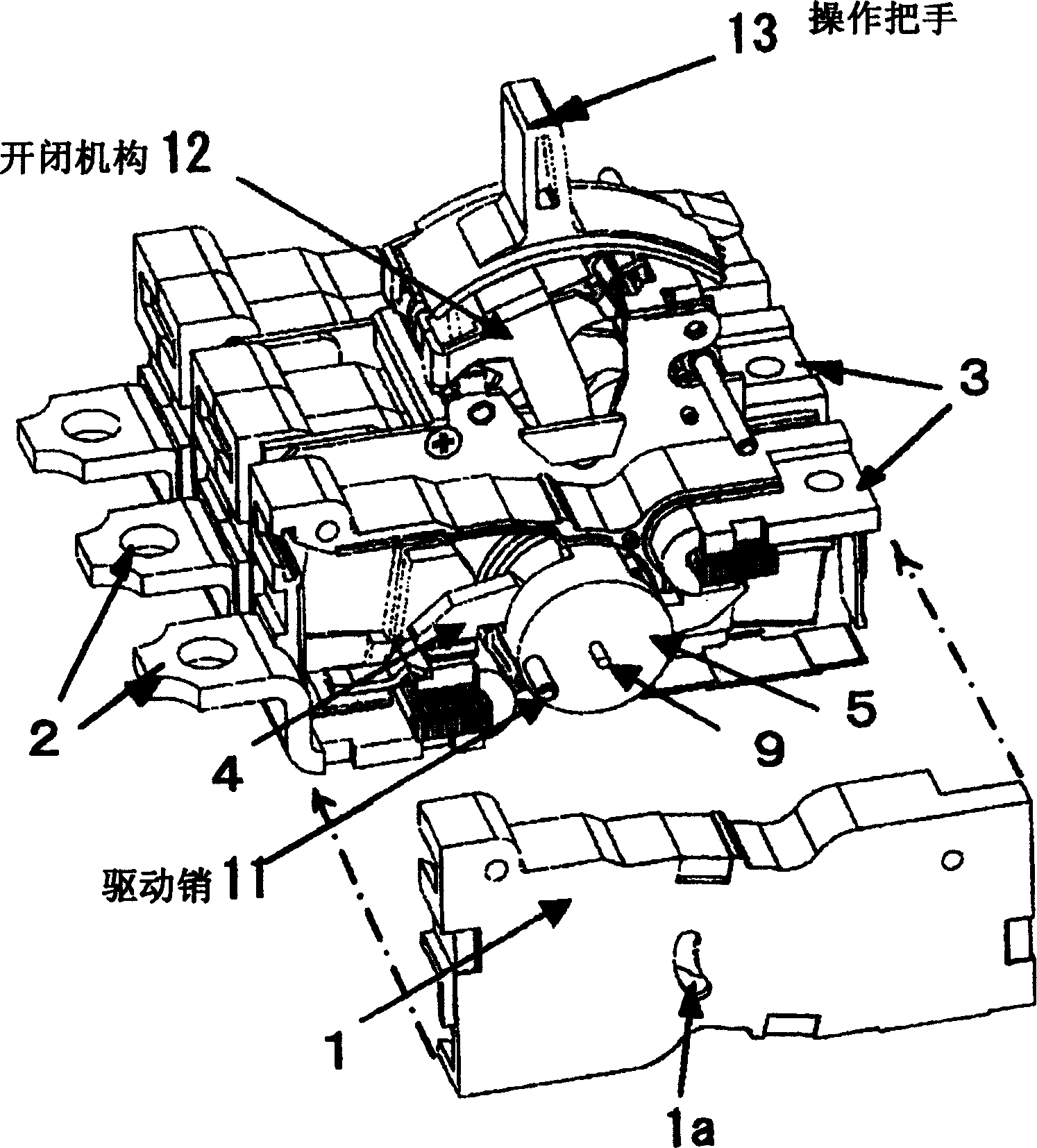

[0048] exist image 3 In this embodiment, the current breaking part of each phase constituting the 3-phase circuit breaker is a structure in which the support shaft 9 penetrating through the rotation center of the movable contact piece 4 and the support shaft of the contact sub-support 5 are used in the previous embodiment. .

[0049] That is, the support shaft 9 penetrates through the center of rotation of the contact holder 5, and its shaft end is supported by a bearing part (not shown) formed inside the case 1 (two-part structure) of the current interrupting part, so that the movable contact The member 4 and the contact member bracket 5 are pivotally supported possibly in rotation. Further, in addition to the above-mentioned support shaft 9, a common drive pin 11 is provided for each phase of the arc-shaped shaft hole 1a that penetrates the contact bracket 5 and the side wall surface of the housing 1, so that the drive pin 11 passes through in a left and right direction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com