Structure for reducing notice in vacuum cleaner

A vacuum cleaner and noise technology, which is applied in the direction of vacuum cleaners, cleaning equipment, household appliances, etc., to achieve the effect of simple structure, significant noise reduction effect, and prolonging the exhaust flow path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

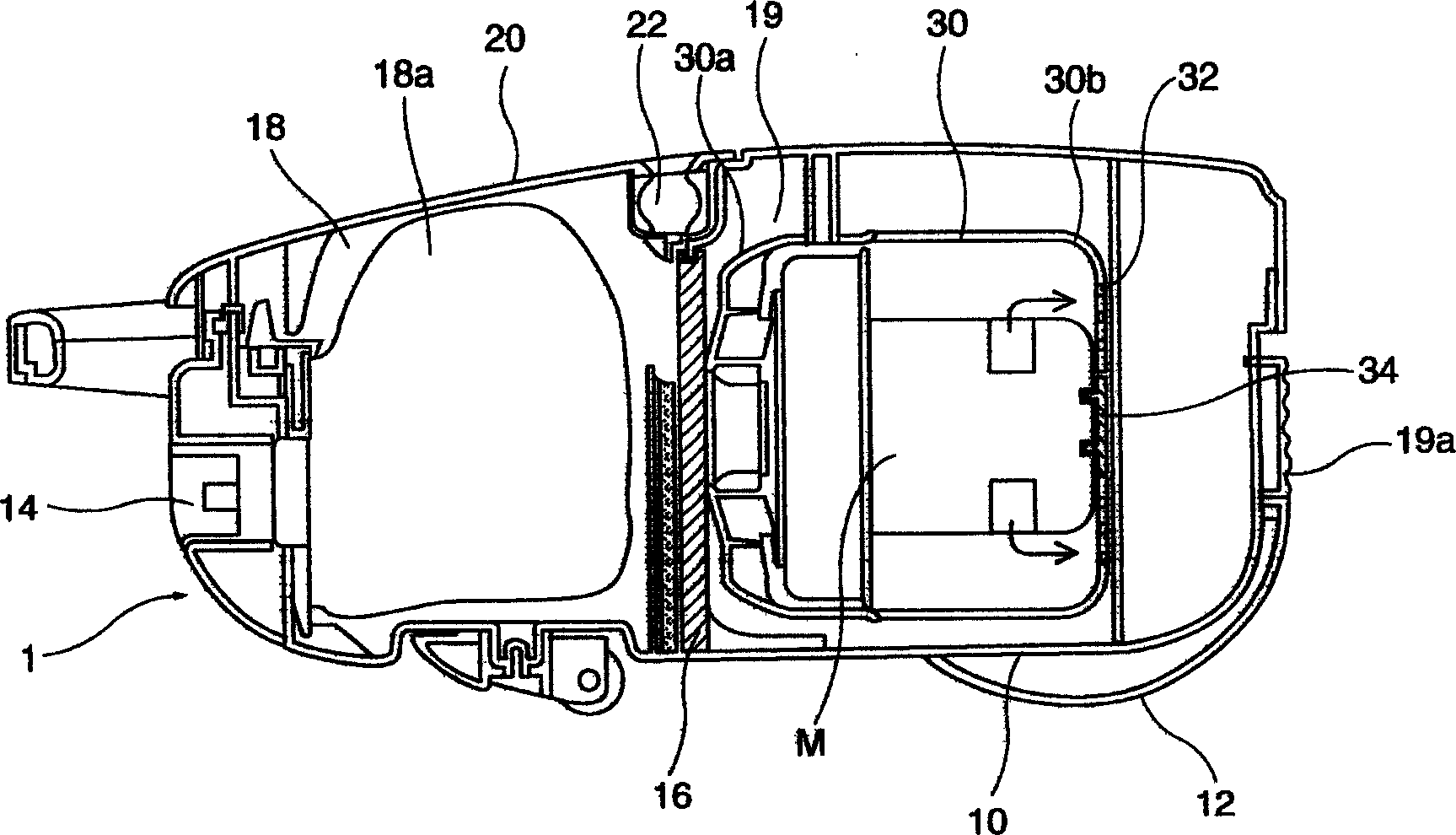

Embodiment approach 1

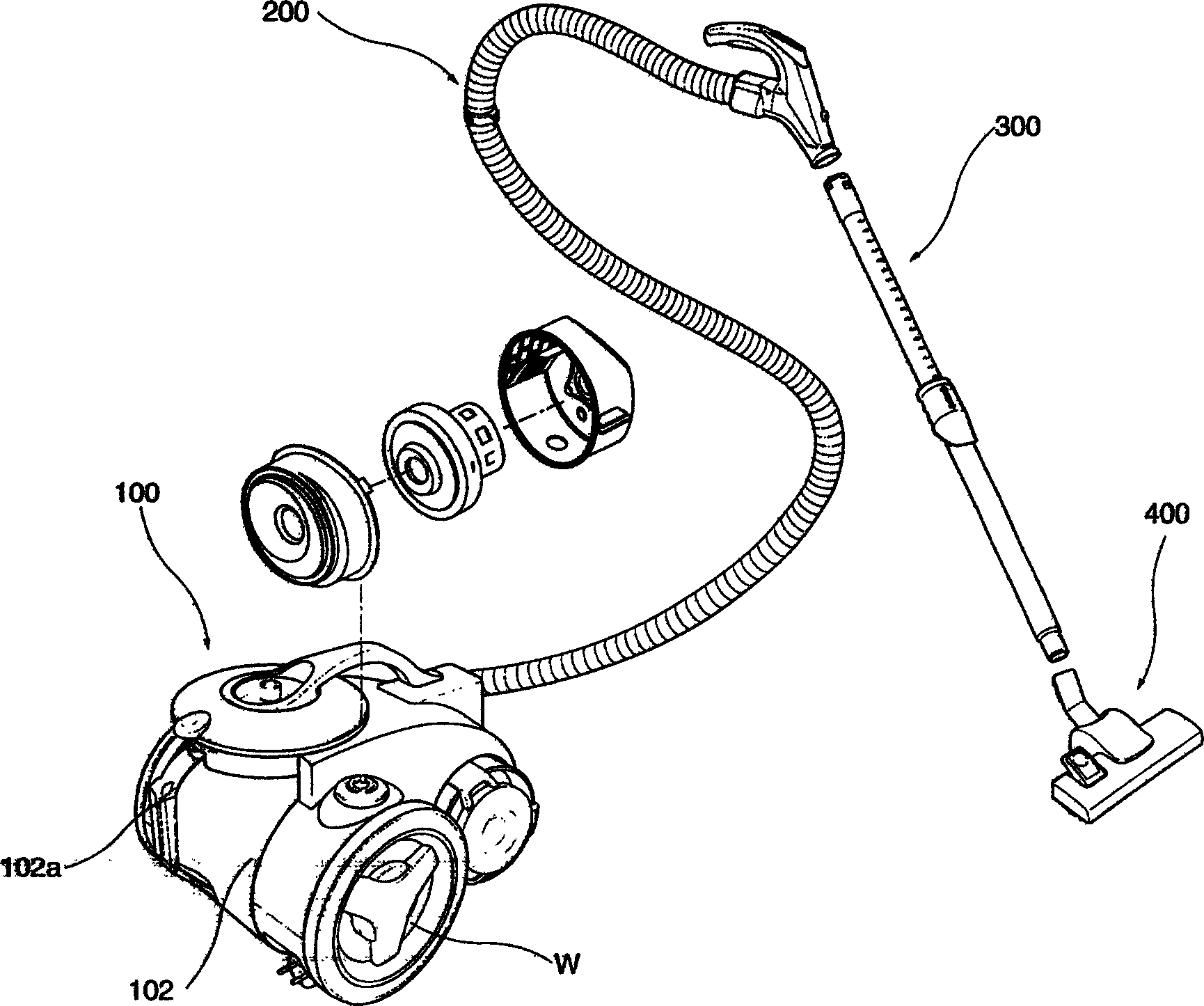

[0025] Such as figure 2 As shown, the vacuum cleaner adopting the noise reduction structure of the vacuum cleaner of the present invention includes: a main body 100, an extension pipe 300, an air suction pipe 200 and a suction nozzle 400; the inside of the main body 100 is provided with a fan motor M (not shown in the figure) output), the fan motor M is used to generate suction, and the dust and foreign objects are sucked into the main body 100 through the suction pipe 200, the extension pipe 300 and the suction nozzle 400.

[0026] The two sides of the rear part of the body 100 are respectively provided with a wheel W, the wheel W is designed to be half the size of the body 100, therefore, the position can be moved freely without being affected by the shape of the floor to be cleaned, and the rim of the wheel W covers There is a non-slip layer made of rubber or urethane material.

[0027] The rear part of the main body 100 is provided with a dust collecting device 102, the ...

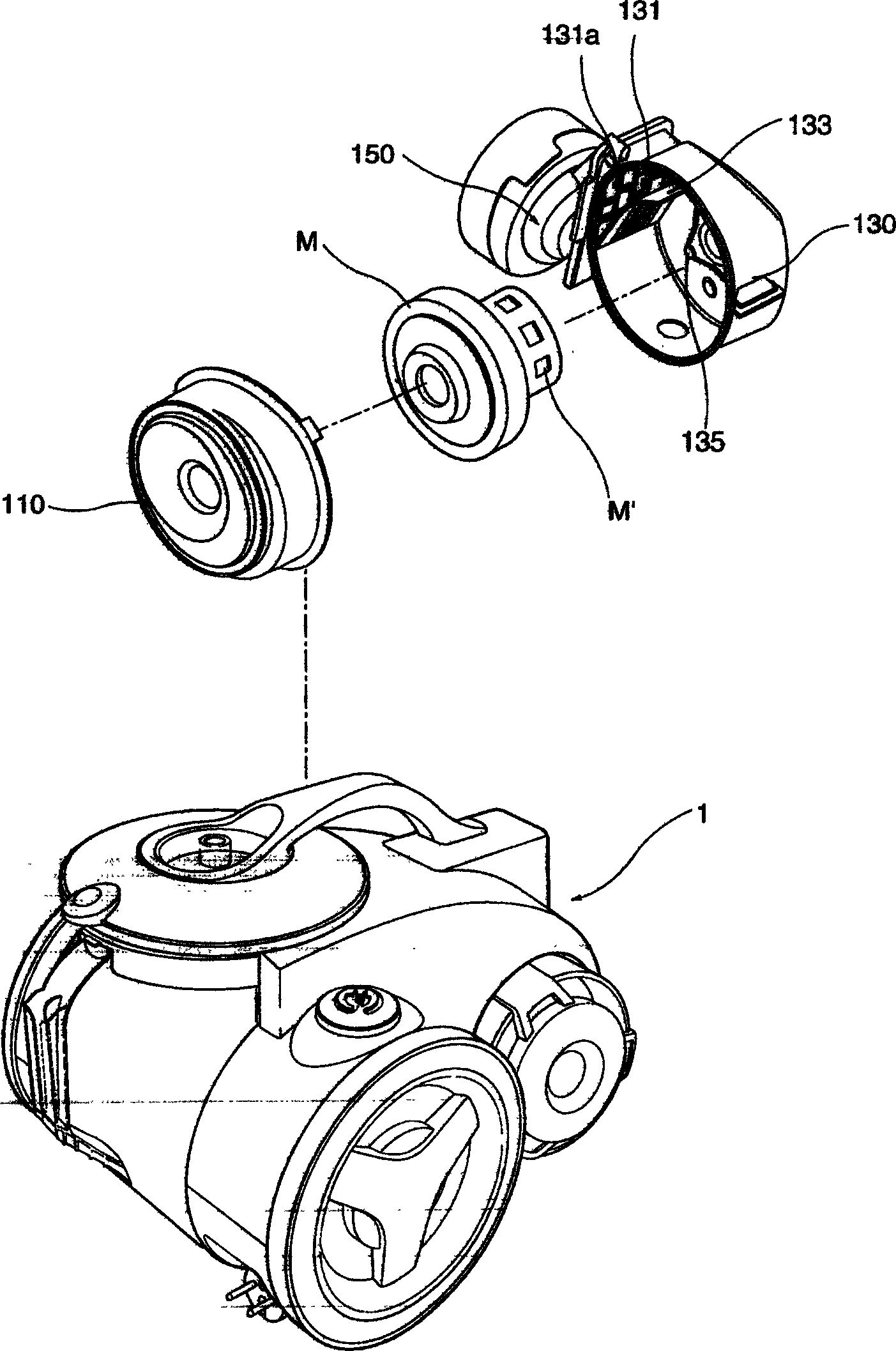

Embodiment approach 2

[0039] More than one guide rib 133 is provided on the inner side of the rear housing 130; a damping pad made of cloth or sponge is provided between the fan motor M and the rear housing 130; other structures and implementations Method 1 is the same. The noise reduction effect of this embodiment is more remarkable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com