Dynamo of vacuum duster having brush

A technology for vacuum cleaners and electric brushes, which is applied in the direction of vacuum cleaners, electrical components, electromechanical devices, etc., which can solve the problems of increased number of assembly processes, impact of brushes 131, increased noise, etc., so as to reduce the number of assembly processes and prevent loosening And/or falling off, the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings.

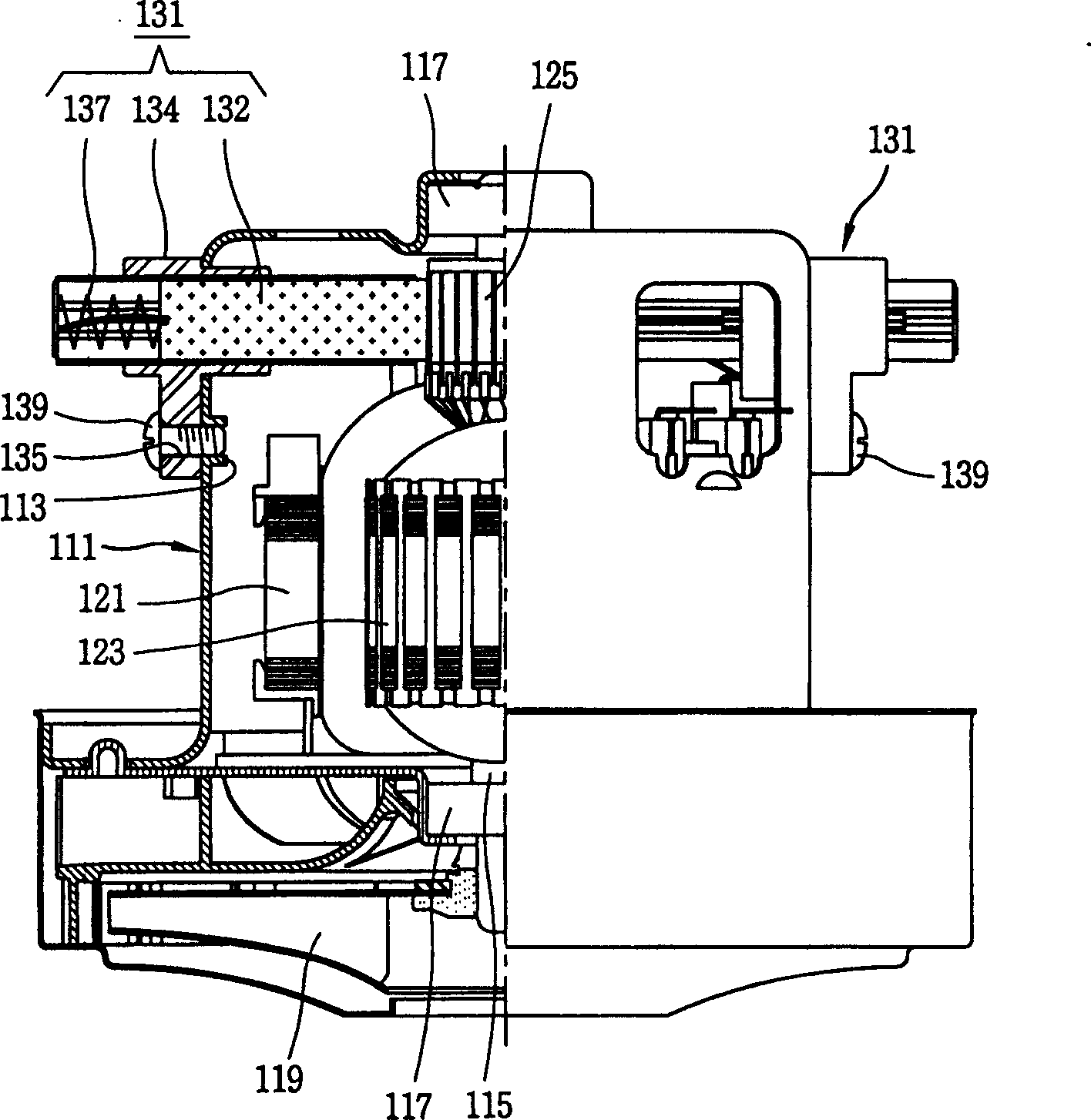

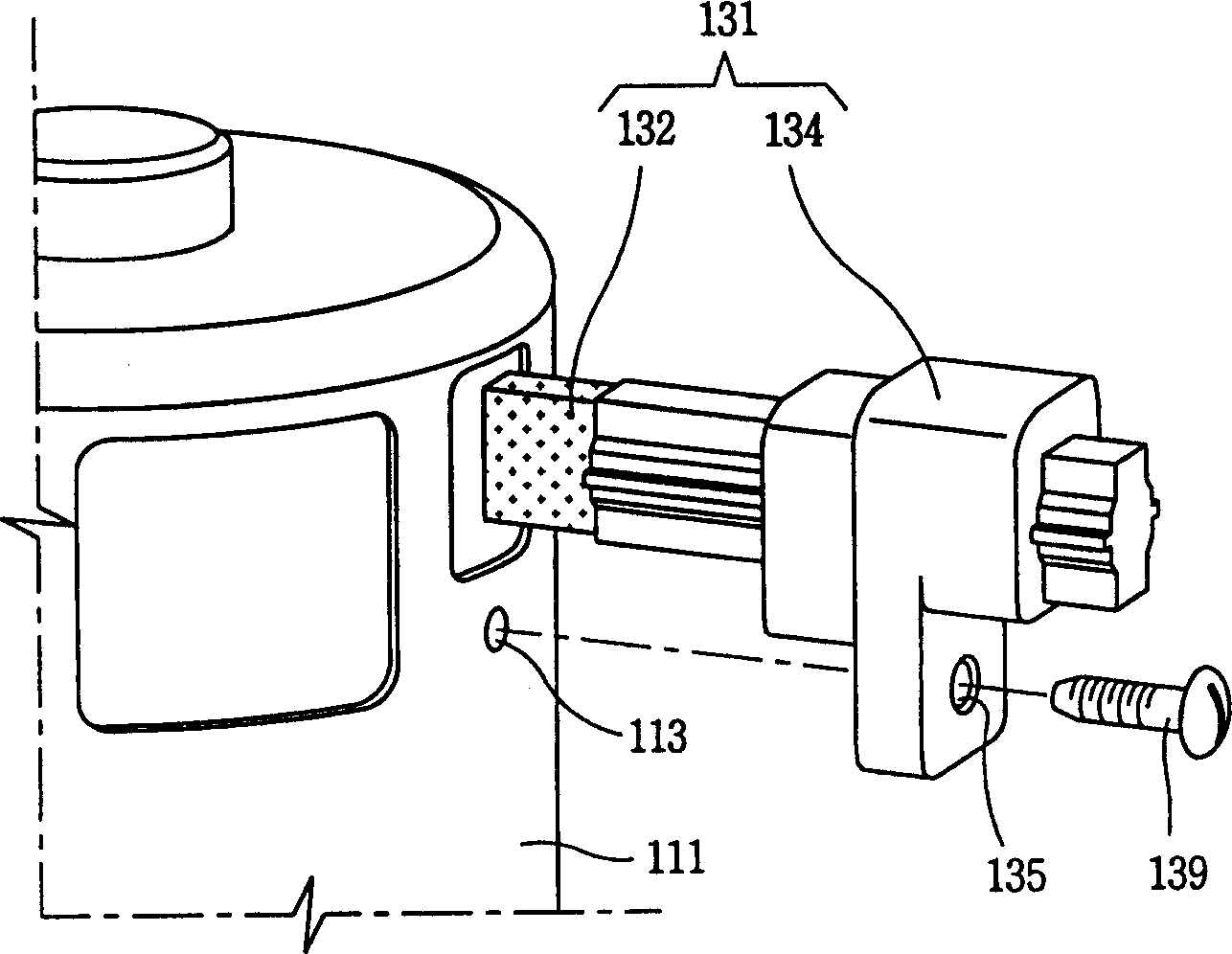

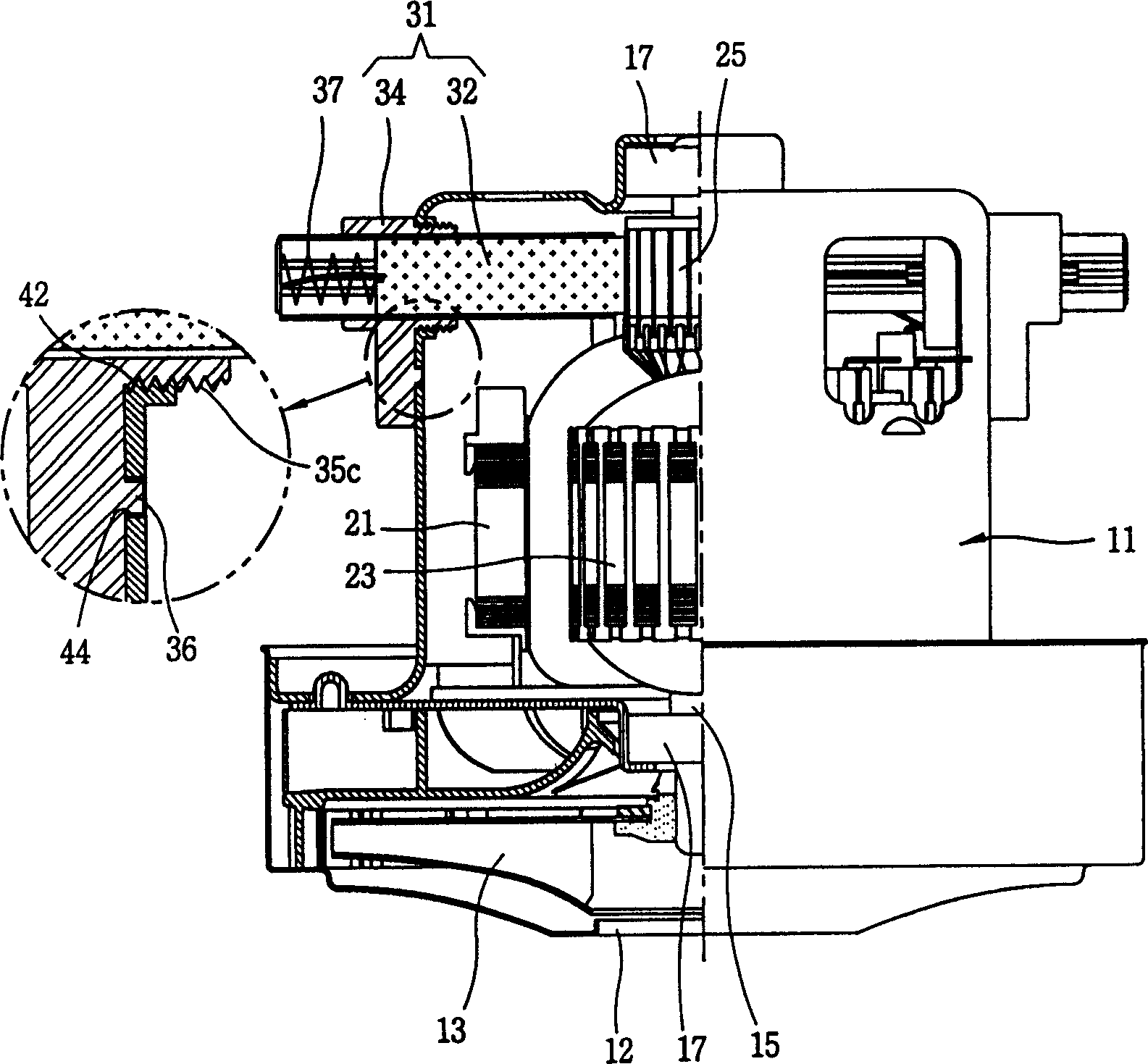

[0027] image 3 It is a half-sectional view of a brush-equipped vacuum cleaner motor employing an example of the present invention, Figure 4 for image 3 An exploded side view of the brush section, Figure 5 for along Figure 4 An enlarged cross-sectional view of the V-V line. As shown in the figure, the vacuum cleaner motor equipped with brushes of the present invention comprises the following structures, that is, a housing 11, which forms an accommodation space inside; a rotating shaft 15, which is installed in the inside of the above-mentioned housing 11 and can rotate; A sub 25 is connected to one side of the above-mentioned rotating shaft 15, and can rotate together with the above-mentioned rotating shaft 15; a brush 31 with a carbon rod 32 and a bracket 34, wherein one end of the above-mentioned carbon rod is in contact with the above-mentioned commutator 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com