Technique for manufacturing ceramic glazed tile with natural stone texture

A technology of ceramic polished tiles and production process, which is applied in the direction of imitating natural patterns, decorative arts, clay products, etc., and can solve the problems of irregularities, unsatisfactory production effects, and difficult control of ceramic patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

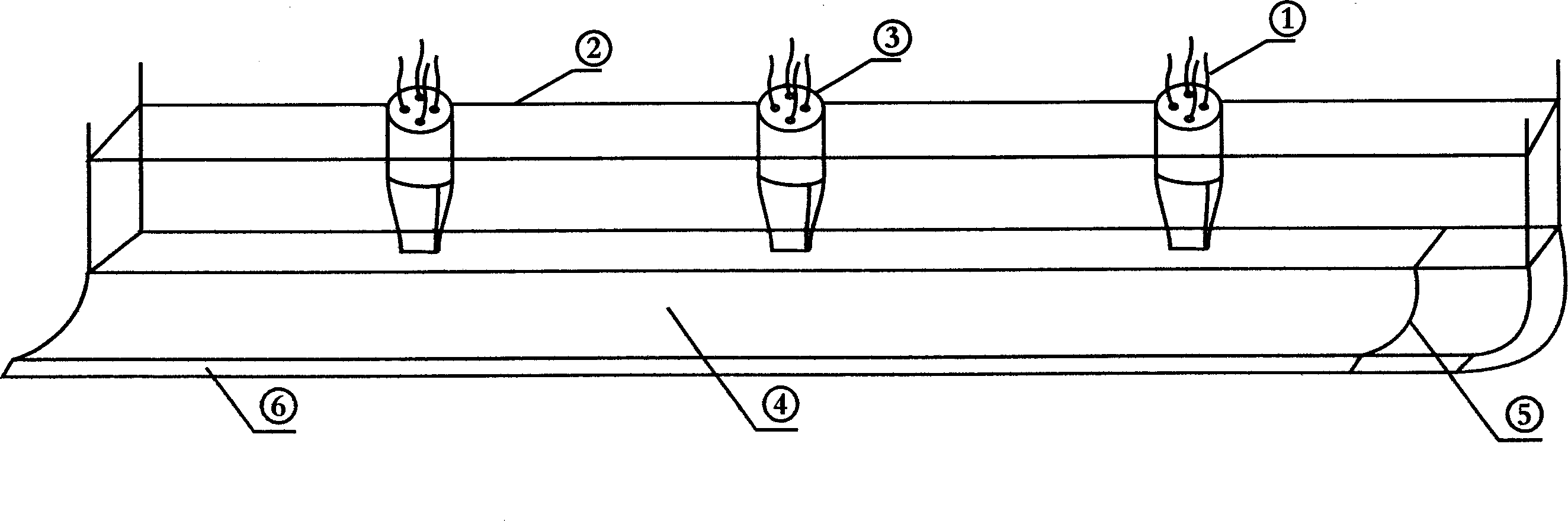

[0012] The edge thickness of the pressing machine is about 4mm, and the depth is about 4mm. Equipment fabric, after the work is completed, is conveyed horizontally until the water curtain disappears, and then enters the kiln for drying and firing, and finally cuts the edges and polishes them for grading and packaging.

[0013] Distributing equipment adjustment: 1. The stirring speed of the mixing equipment 2. The height of the beam 3. The left and right translation range of the mixing equipment along the beam 4. The height of the color paste in the slurry storage chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com