Method and device for rapidly detecting tenderness of beef utilizing near infrared technology

A technology in the near-infrared and near-infrared ranges, applied in measuring devices, color/spectral characteristic measurement, material analysis through optical means, etc., to achieve objective results, avoid interference from human factors, and easy detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

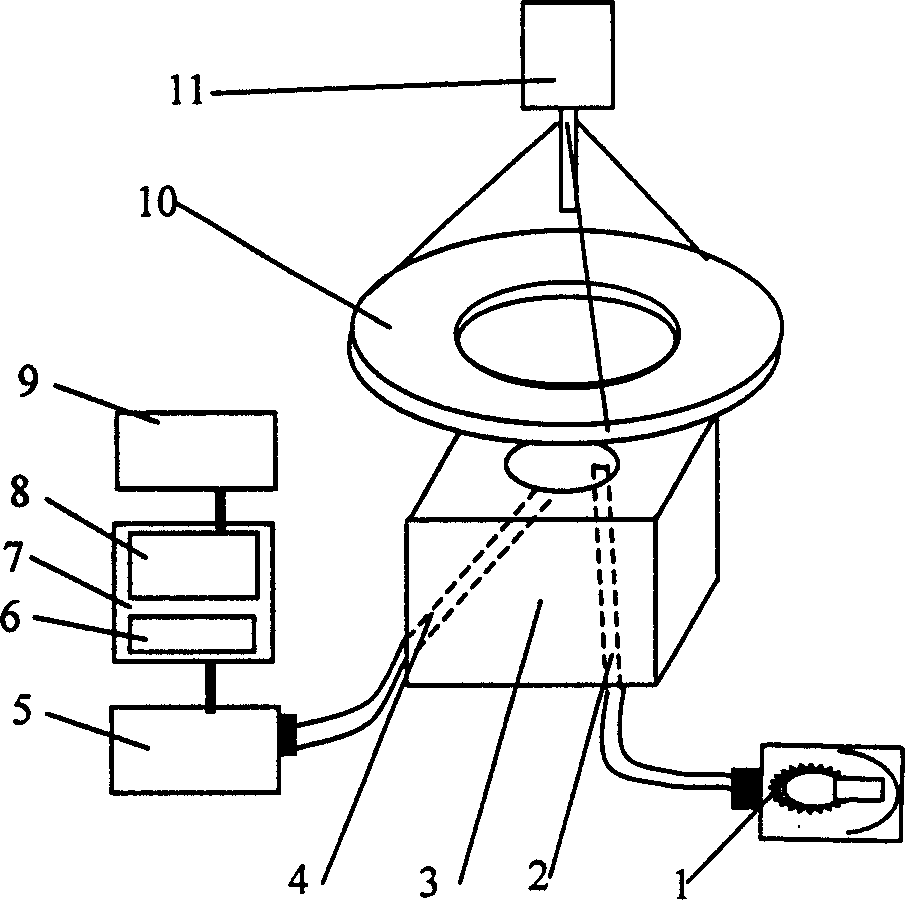

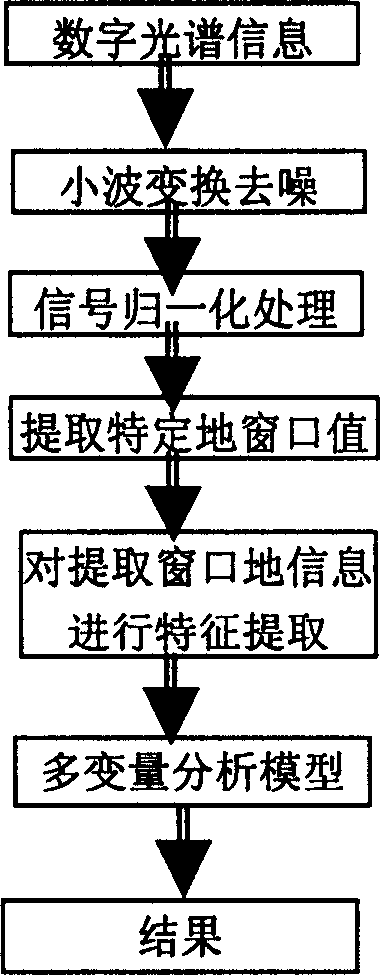

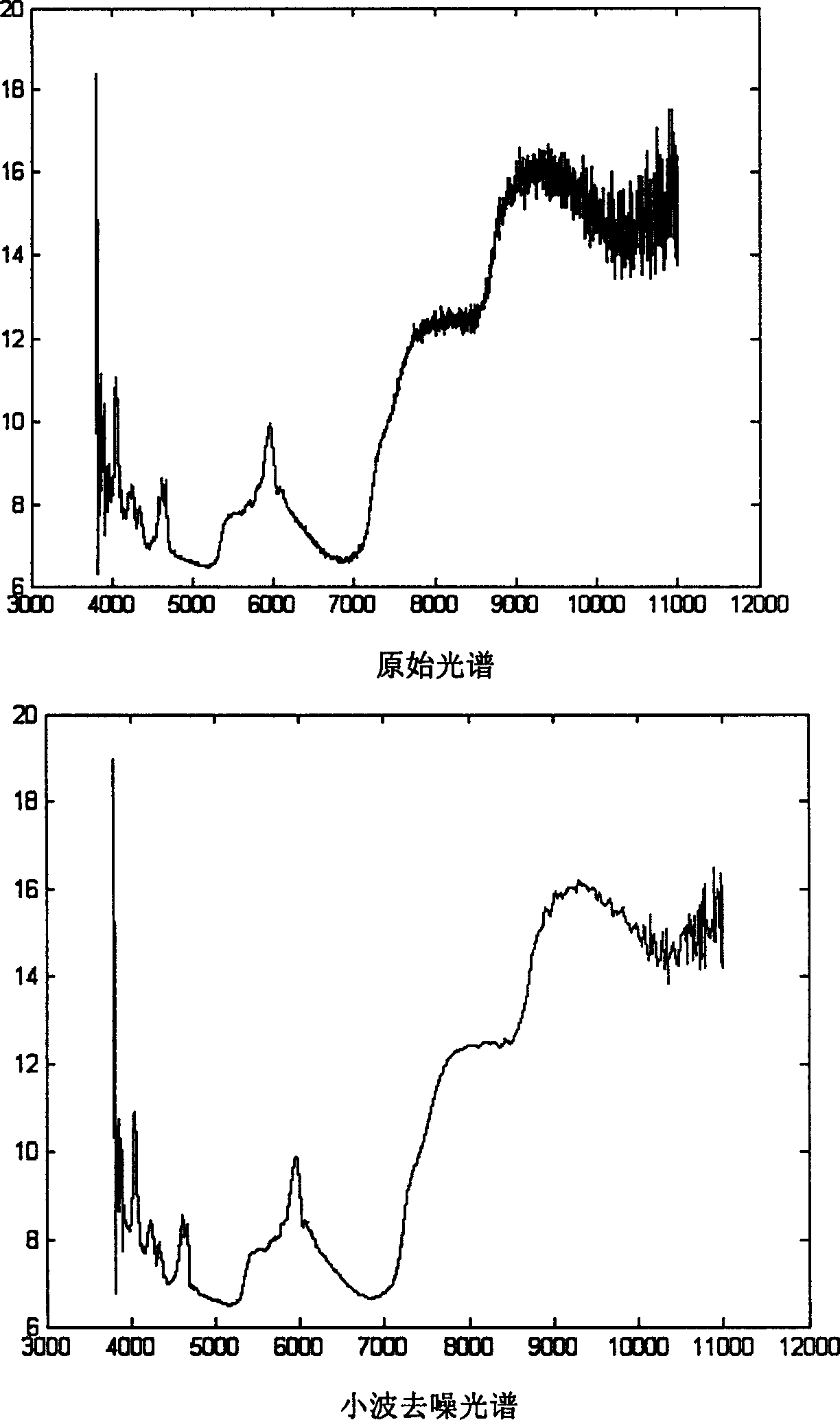

[0020] like figure 1 Place the measured beef on the rotatable stage 10 with a round hole in the center, and rotate slowly and steadily with the rotatable stage 10 under the drive of the stepping motor 11; the diffuse reflection optical fiber device 3 is eccentrically placed on the rotatable Below the stage 10, it consists of an incident optical fiber 2 connected to a near-infrared light source 1 and a receiving optical fiber 4 connected to a near-infrared detector 5, and the near-infrared detector 5 converts the collected near-infrared signal into an analog voltage signal, the analog voltage signal is converted into a digital signal through the analog-to-digital converter 6 in the microprocessor 7, and the digital signal is provided to the data processing module 8 in the microprocessor 7, and passed in the data processing module 8, and the data processing process like figure 2 As shown, firstly, the wavelet transform is performed on the spectral information, the noise is rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com