Polarizing film mask slice with high resolution

A high-resolution, polarizing film technology, used in optics, instruments, photolithography on pattern surfaces, etc., can solve the problem of high manufacturing cost, inability to guarantee high-quality imaging, optimal phase shifter design, and difficulty in placement Large and other problems, to achieve the effect of convenient production, reducing proximity effect, and improving lithography resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below the present invention will be described in further detail in conjunction with accompanying drawing:

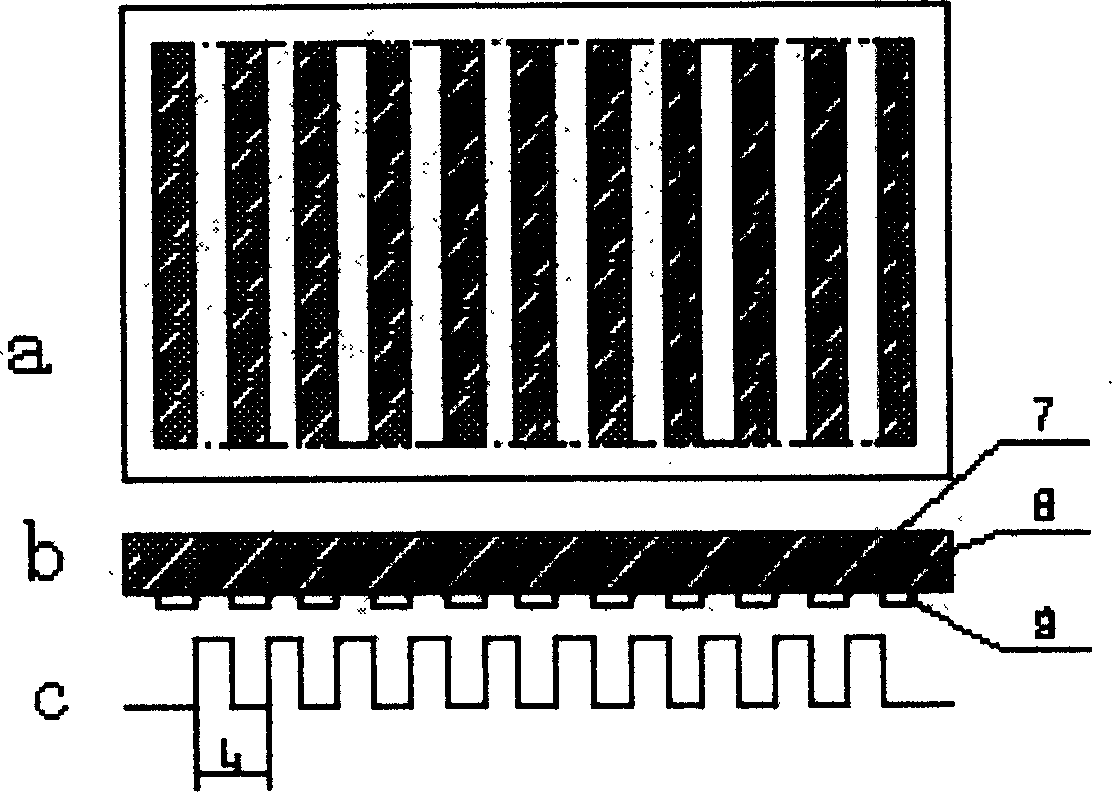

[0026] Such as figure 1 a, 1b, and 1c show conventional masks. The light-transmitting regions 8 and the opaque regions 9 are alternately arranged to form a mask pattern, and the corresponding mask amplitude transmittance is as follows: figure 1 Shown in c; the amplitude transmittance is relatively high in the light-transmitting region 8, and very low (amplitude transmittance=0) in the light-transmitting region 9, then a pair of adjacent light-transmitting regions 8 and light-impermeable regions 9 The basic period L that makes up the mask pattern 1 .

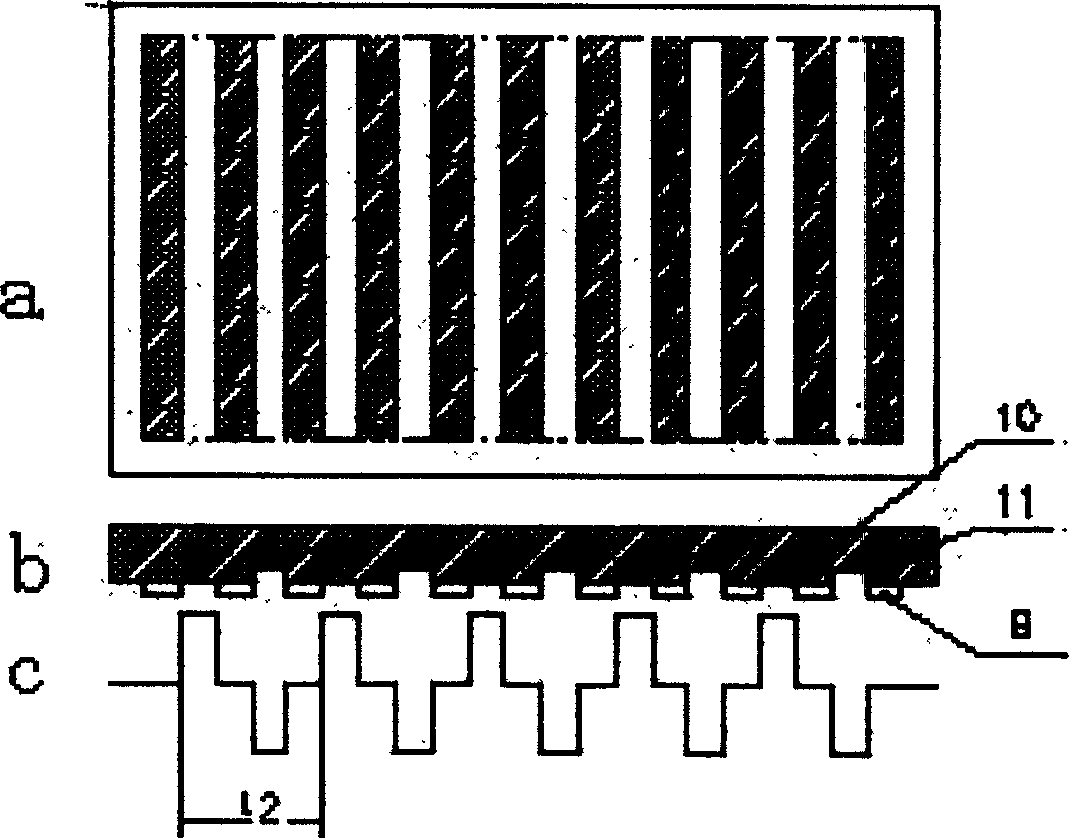

[0027] Such as figure 2 a and 2b are schematic diagrams of the structure of the phase shift mask. There is a phase shift layer at the light-transmitting region 11, and the phase of the imaging beam passing through the adjacent light-transmitting regions 10 and 11 of the light-impermeable region 9 will have a 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com