Asphalt for paving

A technology of asphalt and straight-run asphalt, which is applied in the field of asphalt for traffic road paving, and can solve problems such as cumbersome air blowing operations, road cracks, and easy deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

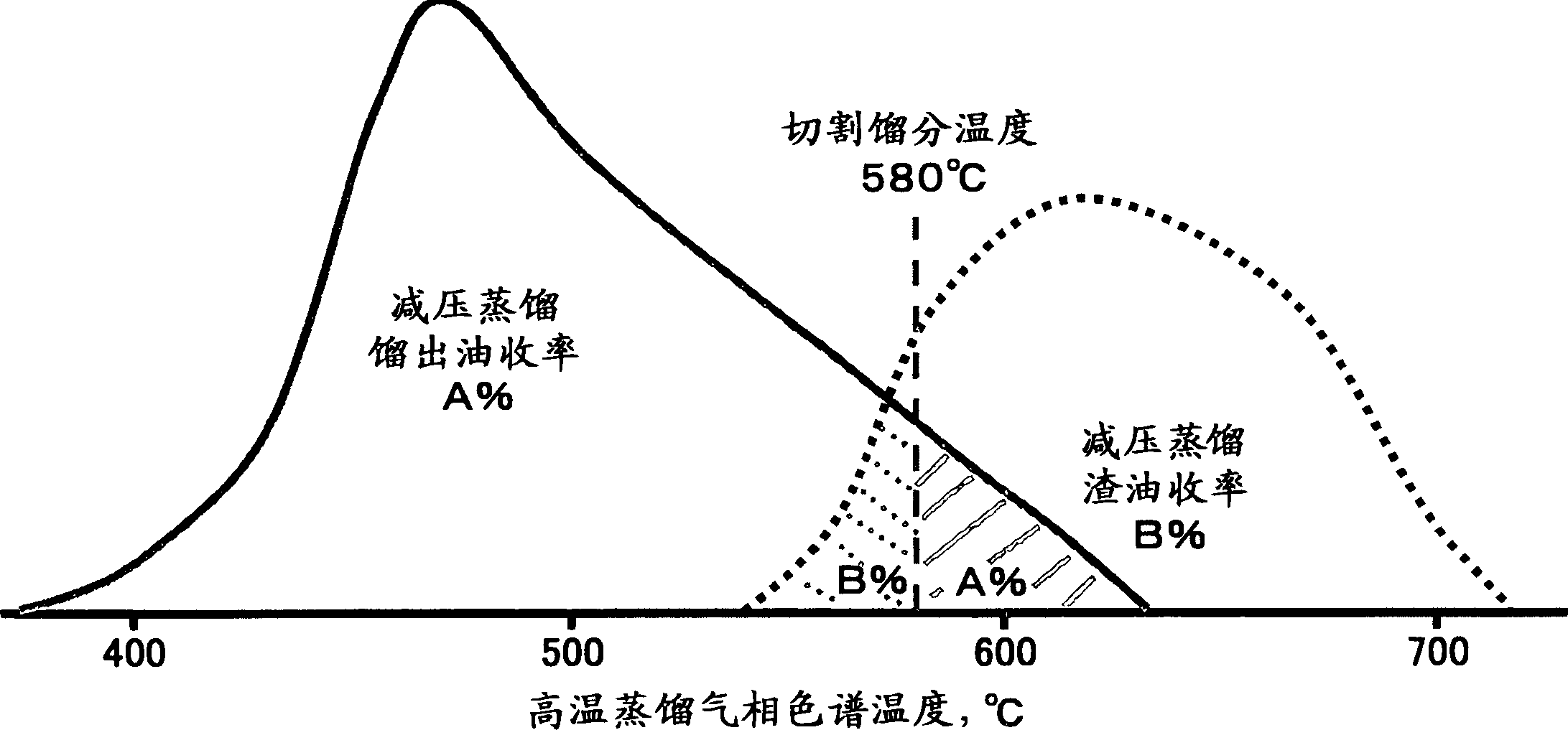

[0112] 50% by volume of crude oil (A) (crude oil (1)) is mixed with 50% by volume of crude oil (a) (crude oil (2)), and the mixed crude oil is subjected to atmospheric distillation. Carry out vacuum distillation at 550°C, 540°C and 530°C respectively to obtain asphalt for paving. The properties of the asphalt are shown in Table 3. The ratio of the elongation to the viscosity of the film heating test of the paving asphalt with a penetration of 48 (1 / 10mm) at 25°C is higher than that of the semi-oxidized asphalt shown in Comparative Example 1 described later. Good performance. In addition, compared with a crude oil-derived straight-run pitch shown in Comparative Example 2 described later, it not only has a large penetration, but also has a high viscosity at 60° C. and other properties are also good.

Embodiment 4

[0114] 50% by volume of crude oil (B) (crude oil (1)) and 50% by volume of crude oil (b) (crude oil (2)) are mixed, the mixed crude oil is subjected to atmospheric distillation, and the obtained atmospheric residue is subjected to vacuum distillation Until the cutting fraction temperature is 570°C, bitumen for road paving is obtained. Table 3 shows the asphalt properties.

Embodiment 5

[0116] 30% by volume of crude oil (B) (crude oil (1)) and 70% by volume of crude oil (b) (crude oil (2)) were mixed, the mixed crude oil was subjected to atmospheric distillation, and the resulting atmospheric pressure was distilled at a cut fraction temperature of 580°C. The residual oil is distilled under reduced pressure to obtain bitumen for road paving. Table 3 shows the asphalt properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap