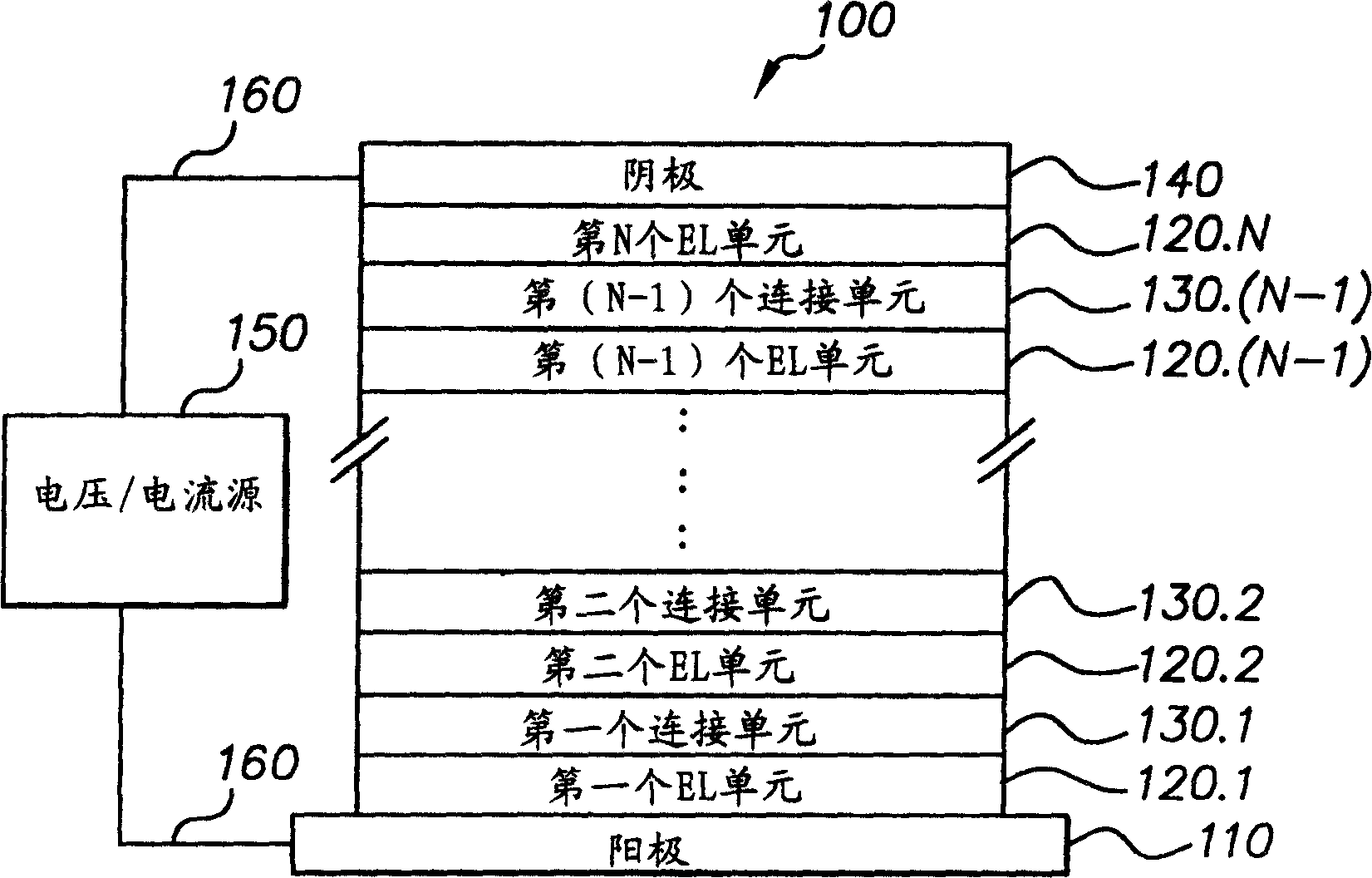

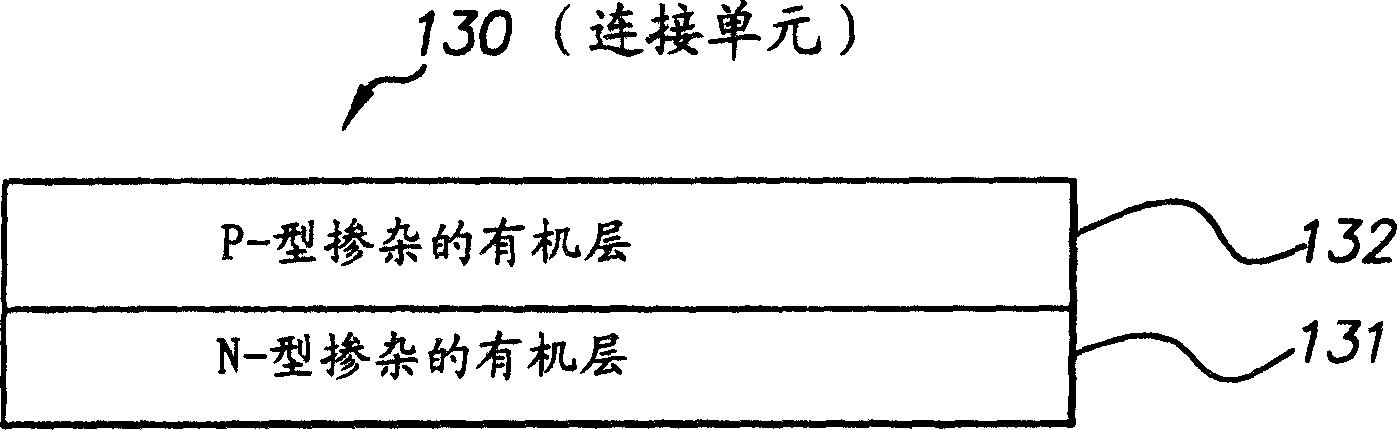

Cascaded organic electroluminescent device having connecting units with n-type and p-type organic layers

A technology of electroluminescent devices and connection units, which is applied in the field of cascaded organic electroluminescent devices, can solve problems such as low output and complexity, and achieve the effects of simplifying production steps, improving light extraction, and high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0175] Embodiment 1 (traditional OLED-comparison)

[0176] A conventional non-cascaded OLED was prepared as follows: an approximately 1.1 mm thick glass substrate coated with a transparent ITO conductive layer was cleaned and dried with an industrial glass washer. The thickness of ITO was about 42 nm and the sheet resistance of ITO was about 68 Ω / square. The ITO surface is then treated with an oxidizing plasma to make its surface available as an anode. By decomposing CHF in an RF plasma processing chamber 3 gas, a 1 nm thick layer of CFx was deposited on a clean ITO surface as a HIL. The substrate was then transferred to a vacuum deposition chamber to deposit all other layers on top of the substrate. at about 10 -6 Under the torg vacuum degree, the following layers are sequentially deposited in the following order through the sublimation of the heated dish:

[0177] (1) HTL, 90nm thick, made of NPB;

[0178] (2) LEL, 20 nm thick, composed of Alq host doped with 1.0 vol% ...

Embodiment 2

[0187] Embodiment 2 (the present invention)

[0188] A cascaded OLED with two EL units was fabricated as follows: an approximately 1.1 mm thick glass substrate coated with a transparent ITO conductive layer was cleaned and dried with an industrial glass washer. The thickness of ITO was about 42 nm and the sheet resistance of ITO was about 68 Ω / square. The ITO surface is then treated with an oxidizing plasma to make its surface available as an anode. By decomposing CHF in an RF plasma processing chamber 3 gas, a 1 nm thick layer of CFx was deposited on a clean ITO surface as a HIL. The substrate was then transferred to a vacuum deposition chamber to deposit all other layers on top of the substrate. at about 10 -6 Under the torg vacuum degree, the following layers are sequentially deposited in the following order through the sublimation of the heated dish:

[0189] (1) The first HTL, 60nm thick, made of NPB, acts as a spacer between the transparent anode and the first EL ...

Embodiment 3

[0206] Embodiment 3 (the present invention)

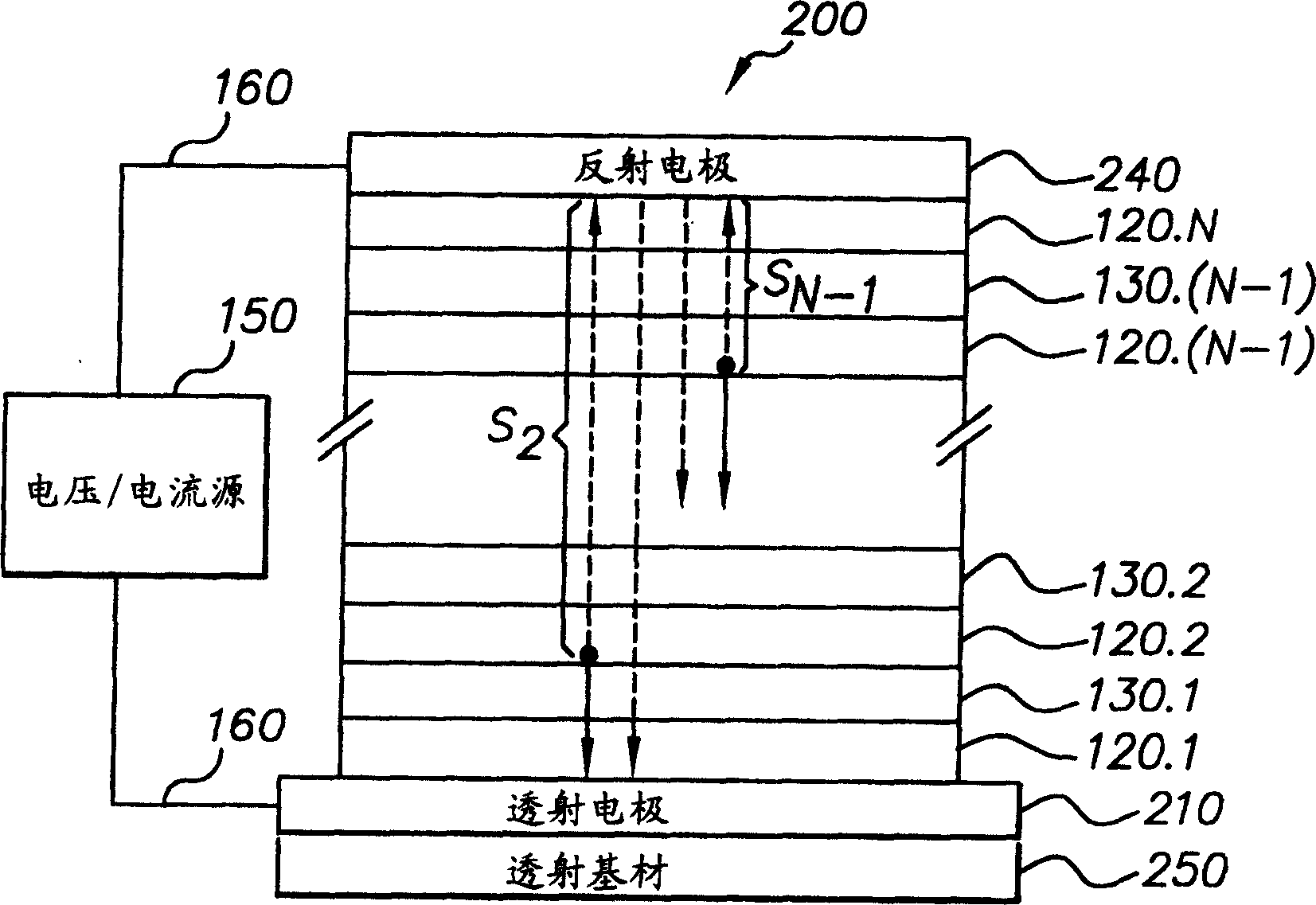

[0207] Except that step (5)-step (9) is repeated once after embodiment 2 step (9) to increase a connection unit and an EL unit, then carry out steps (10) and (11), according to the same method as embodiment 2 A cascaded OLED with three EL units was fabricated.

[0208] After the layers were deposited, the device was transferred from the deposition chamber to a dry box for sealing. The complete device structure is defined as ITO / CFx / NPB(60) / EL / CU / EL / CU / EL / Alq(30) / Mg:Ag.

[0209] Same as Example 2, in this cascaded OLED, the resistivity of the connection unit is higher than 10Ω-cm and the light transmittance is higher than 90%. The emission peak wavelength λ of each LEL is 524 nm. S 3 = S 3,O =95nm, S 2 =1.01×S 2,O = 362nm, and S 1 =1.02×S 1,O = 1.02 x 619 = 629 nm. The optical distance between each emission center plane and the Mg:Ag reflective cathode was optimized. Furthermore, the physical separation between each emiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com