Net cage for fish culture

A technology of cages and nets, applied in fish farming, application, climate change adaptation, etc., can solve problems such as limiting the expansion of cage culture space, inability to eat normally, and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

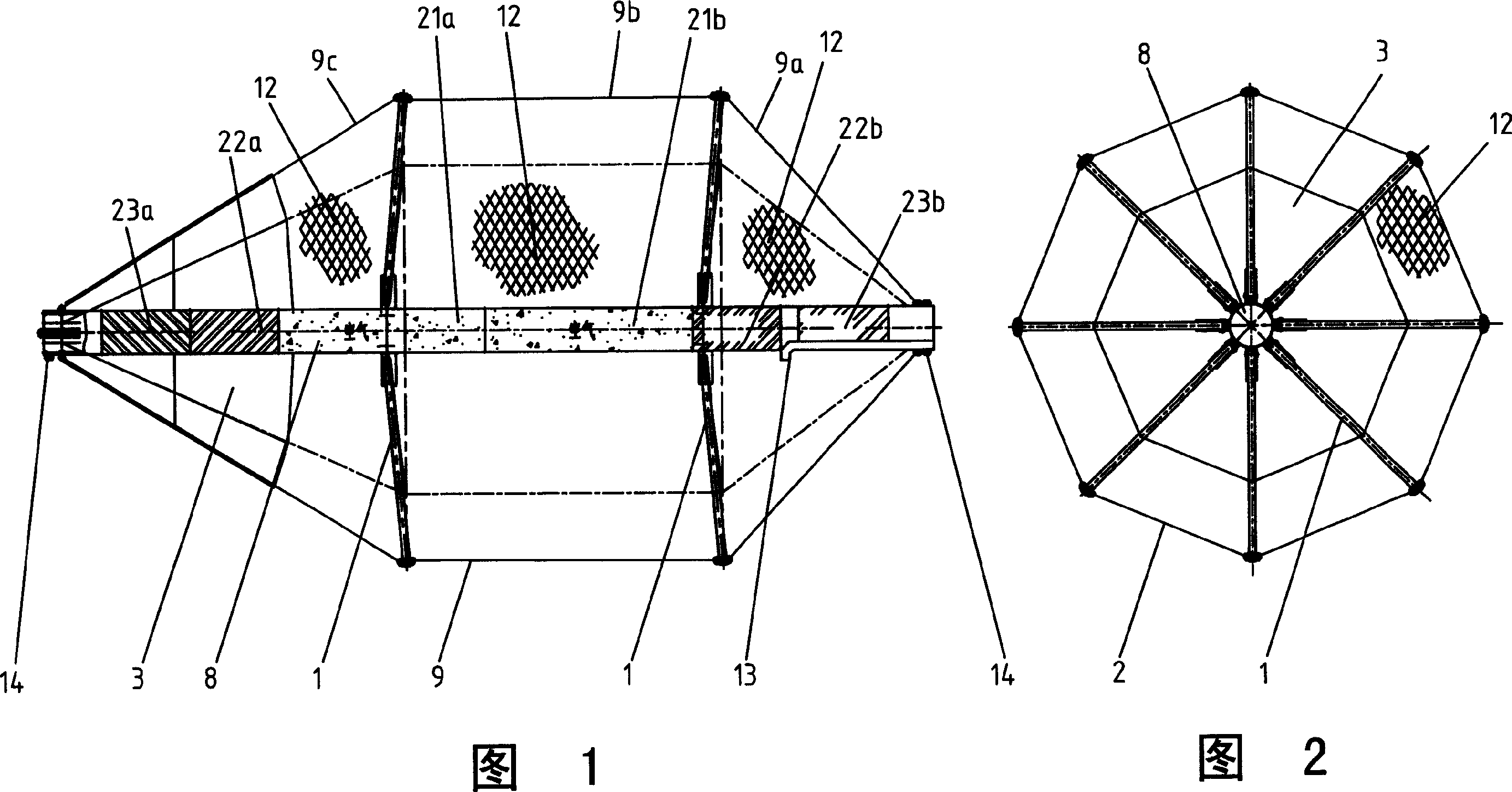

[0023] Figures 1 and 2 are schematic diagrams of the structure of the fish culture cage according to the first embodiment of the present invention. The center of the fish culture cage is provided with a horizontal rigid structure—the central pontoon 8, which has at least One row of support rods 1, two rows of support rods 1 are exemplified in this embodiment.

[0024] The connection between the two rows of support rods 1 and the central pontoon 8 is hinged support. The use of a hinged connection has the advantage that if the force acting on the support rod 1 is too large, the support rod 1 can swing backwards, which acts as a buffer and prevents the cage structure from being damaged by the instantaneous impact load. The support rods 1 are arranged radially in the circumferential direction of the central pontoon 8.

[0025] Several weft ropes 2 are connected to the top of the support rod 1 one by one to form a loop and are tensioned so that the support rod 1 will not swing in the c...

Embodiment 2

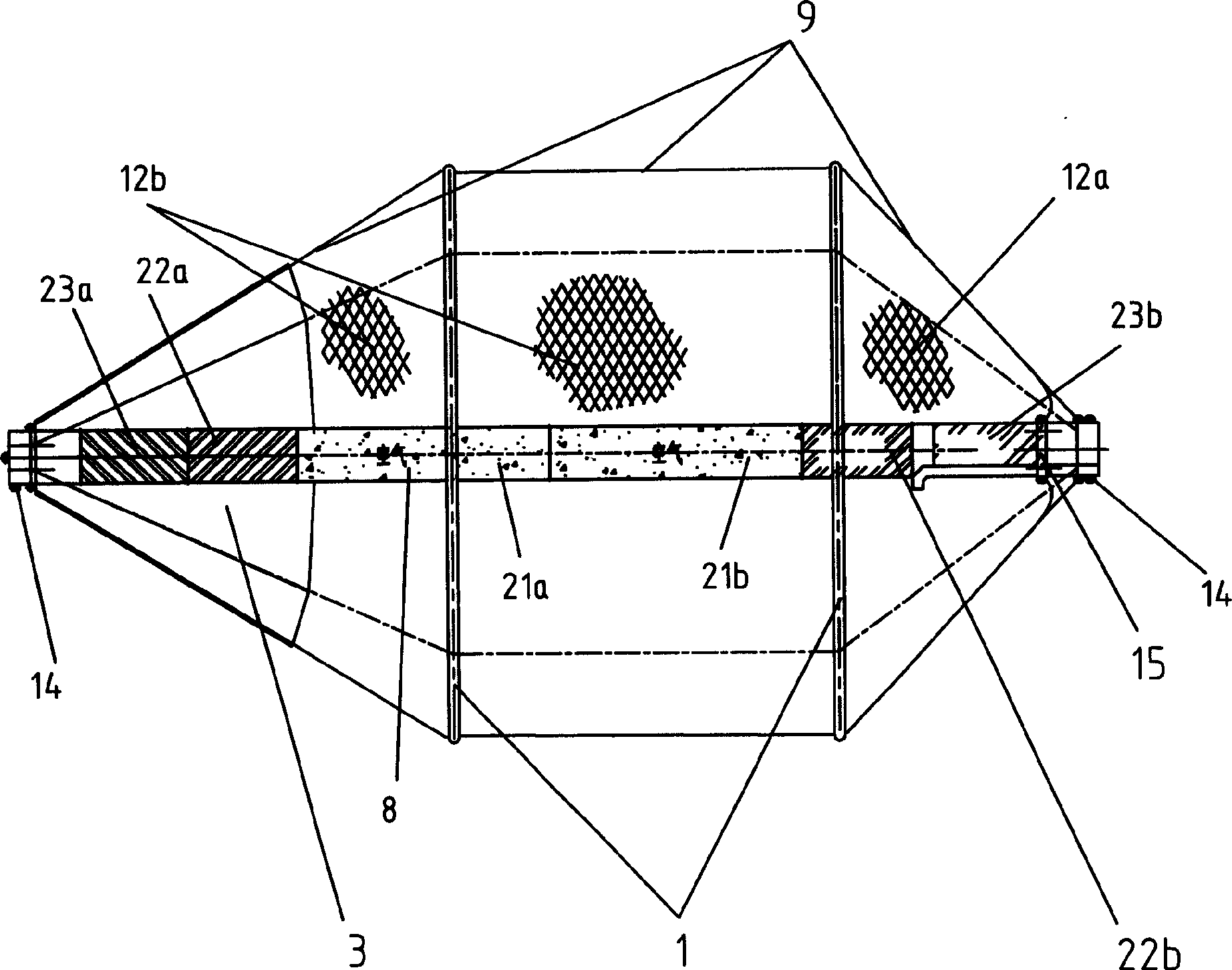

[0033] Such as image 3 , 4 Shown is a schematic structural view of a fish culture cage according to a second embodiment of the present invention. The cage has a horizontal rigid structure-a central pontoon 8, and at least one ring member 24. The example in this embodiment Take two ring members 24.

[0034] The structure and working mode of the center pontoon 8 and its internal air chambers 21a, 21b, inner sinking and floating chambers 22a, 22b, and outer sinking and floating chambers 23a, 23b, and the choke cover 3 are the same as those described in the first embodiment. To repeat.

[0035] The two ring members 24 are arranged on the outer circumference with the central pontoon 8 as the central axis. The ring member 24 referred to here can be multi-deformable (such as triangle, quadrilateral, etc.) or circular ring.

[0036] The warp rope 9 is pulled from one end of the central pontoon 8 to the annular member 24 and connected to it, and then pulled from the annular member 24 to t...

Embodiment 3

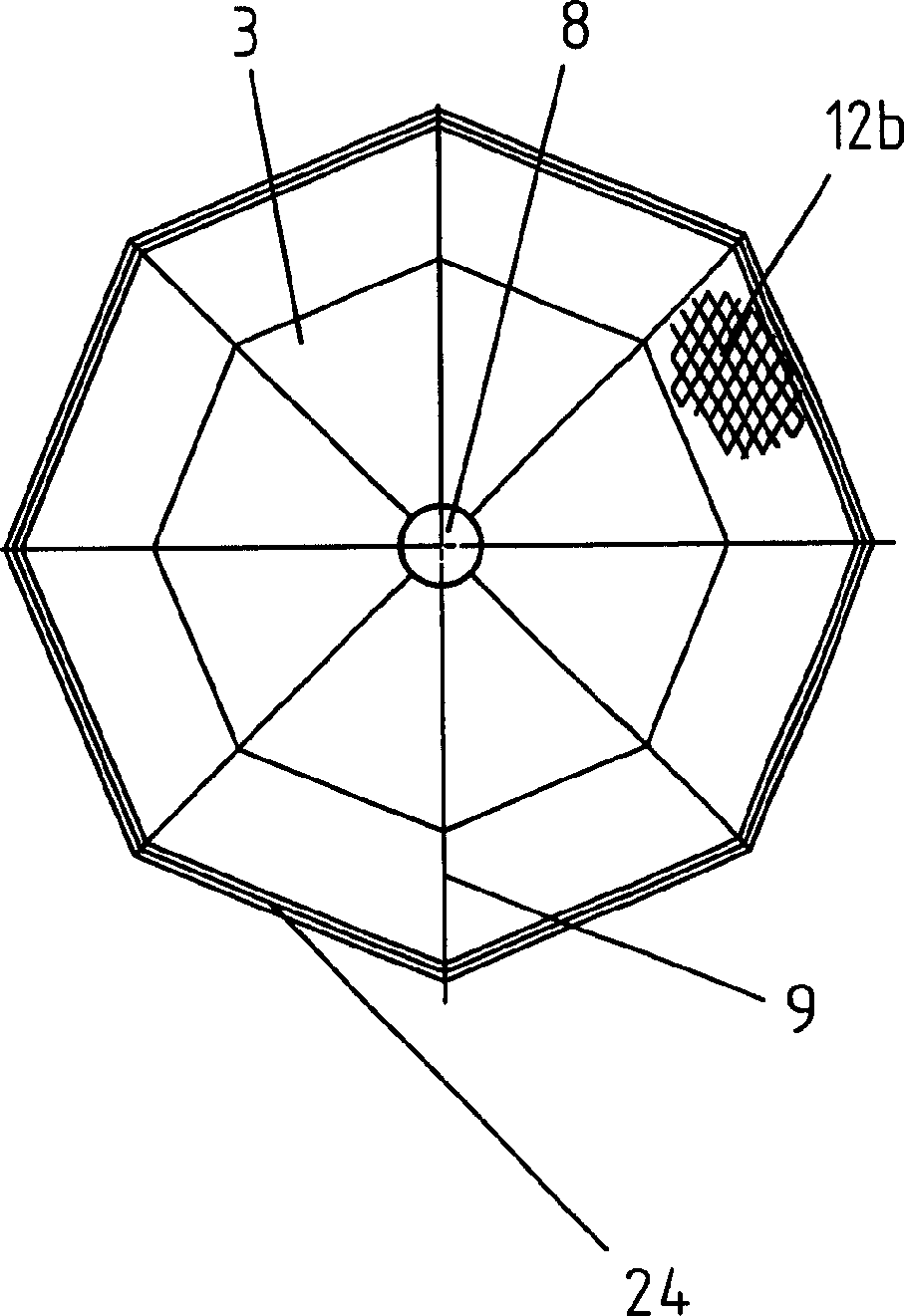

[0040] Figures 5 and 6 are schematic diagrams of the structure of a fish farming cage according to a third embodiment of the present invention. The cage has a horizontal rigid structure-a central pontoon 8, and at least one annular member 24, In this embodiment, two ring members 24 are exemplified.

[0041] The structure and working mode of the center pontoon 8 and its internal air chambers 21a, 21b, inner sinking and floating chambers 22a, 22b, and outer sinking and floating chambers 23a, 23b, and the choke cover 3 are as described in the first embodiment. More details.

[0042] The frame structure of the net cage facing the water flow is a rigid body 16, and the surface is covered with a spherical (or parabolic or pyramidal surface, etc.)-shaped baffle cover 3 to resist the impact of strong water flow. At least one ring member 24 is provided in the middle. The rope 9 is drawn from one end of the central pontoon 8 to the annular member 24 and connected to it, and then drawn from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com