Outside stator for planar motor

A planar motor and stator technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of reduced reliability and efficiency of motors, deformation of magnetic core 11b, etc., to reduce deformation, reduce pressure, and increase contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

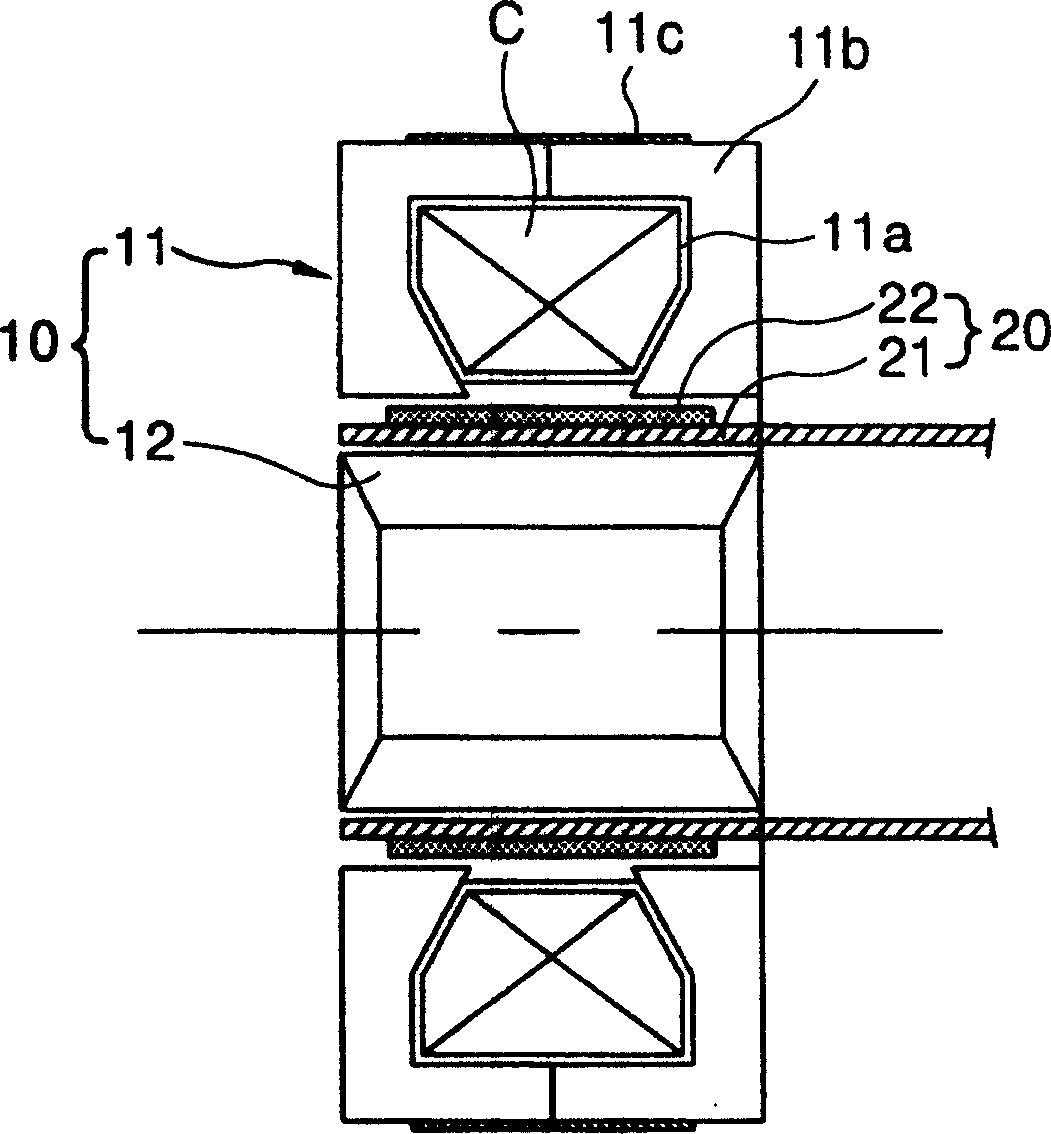

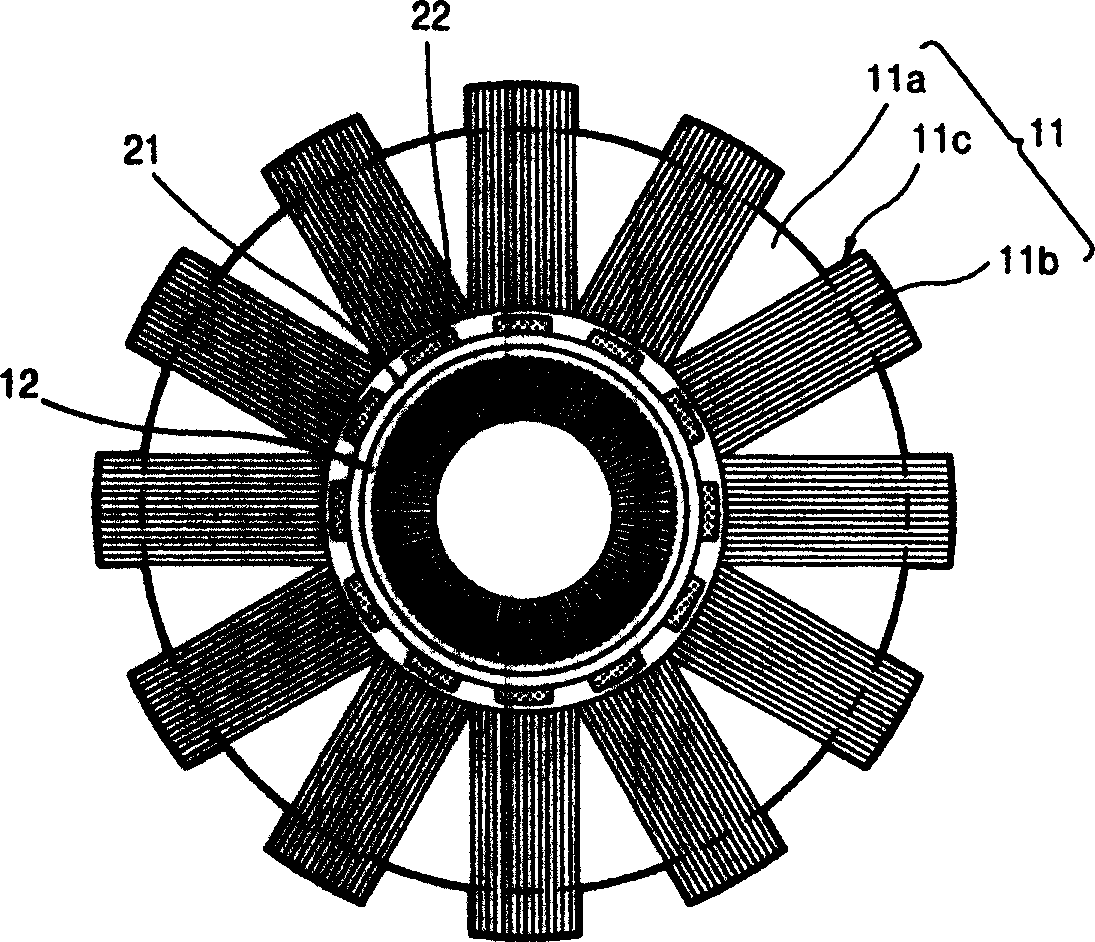

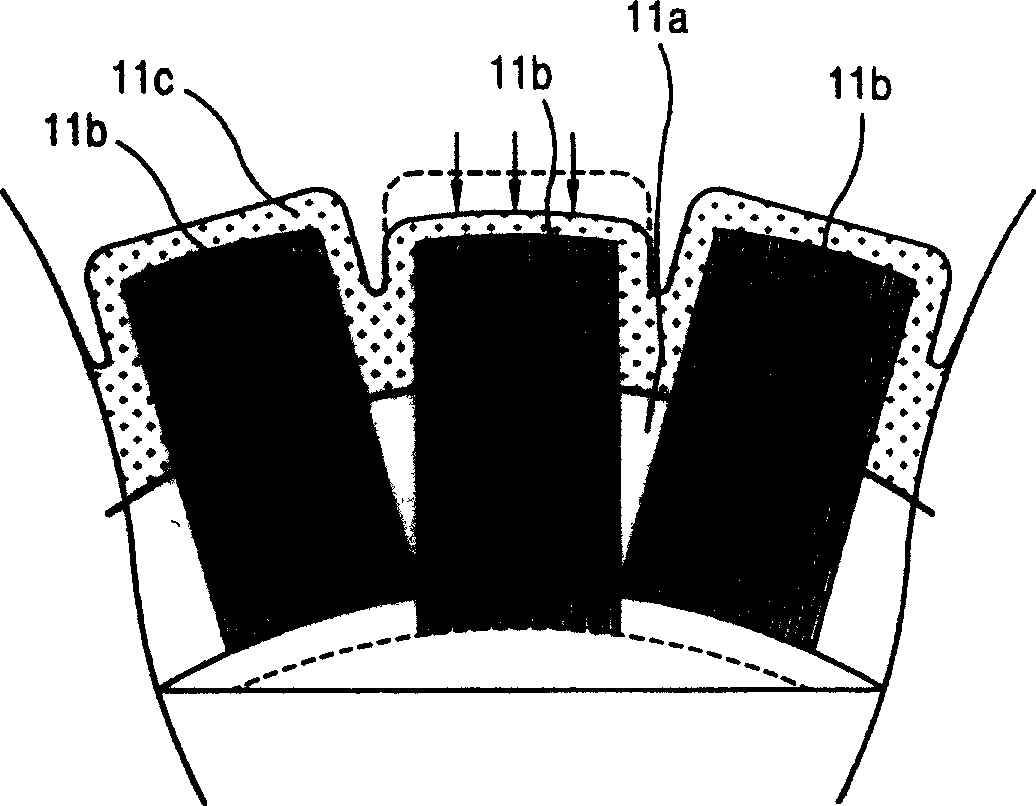

[0013] like Figure 4 ~ Figure 9 As shown, the planar motor provided by the present invention is composed of a stator assembly 100 and a rotor assembly 200 . Wherein, the stator assembly 100 is composed of an outer stator 110 and an inner stator 120 . The outer stator 110 is fixed on the frame. There is a certain gap between the inner stator 120 disposed inside the outer stator 110 and the outer stator 110 . The rotor assembly 200 is disposed in the gap between the outer stator 110 and the inner stator 120, and it can perform linear reciprocating motion. The outer stator 110 is composed of a winding body 111 , a magnetic core 112 and a molded body 113 . The coil C may be embedded in the winding body 111 . The magnetic core 112 is formed by stacking a plurality of stator magnetic cores, which are combined on the outside of the winding body 111 . The molding body 113 can be fixed on the winding body 111 after the connecting portion of the magnetic core 112 is molded. The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com