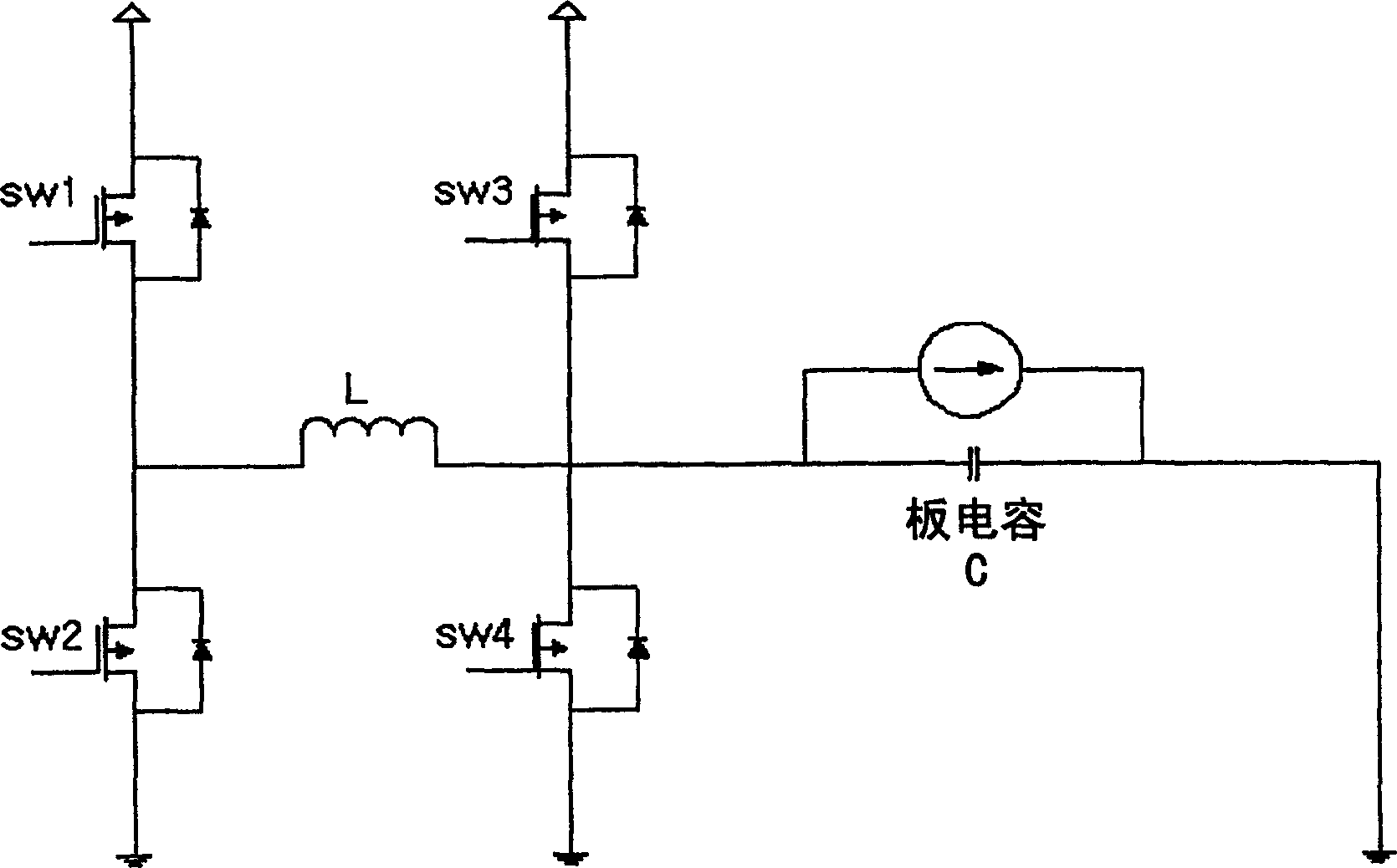

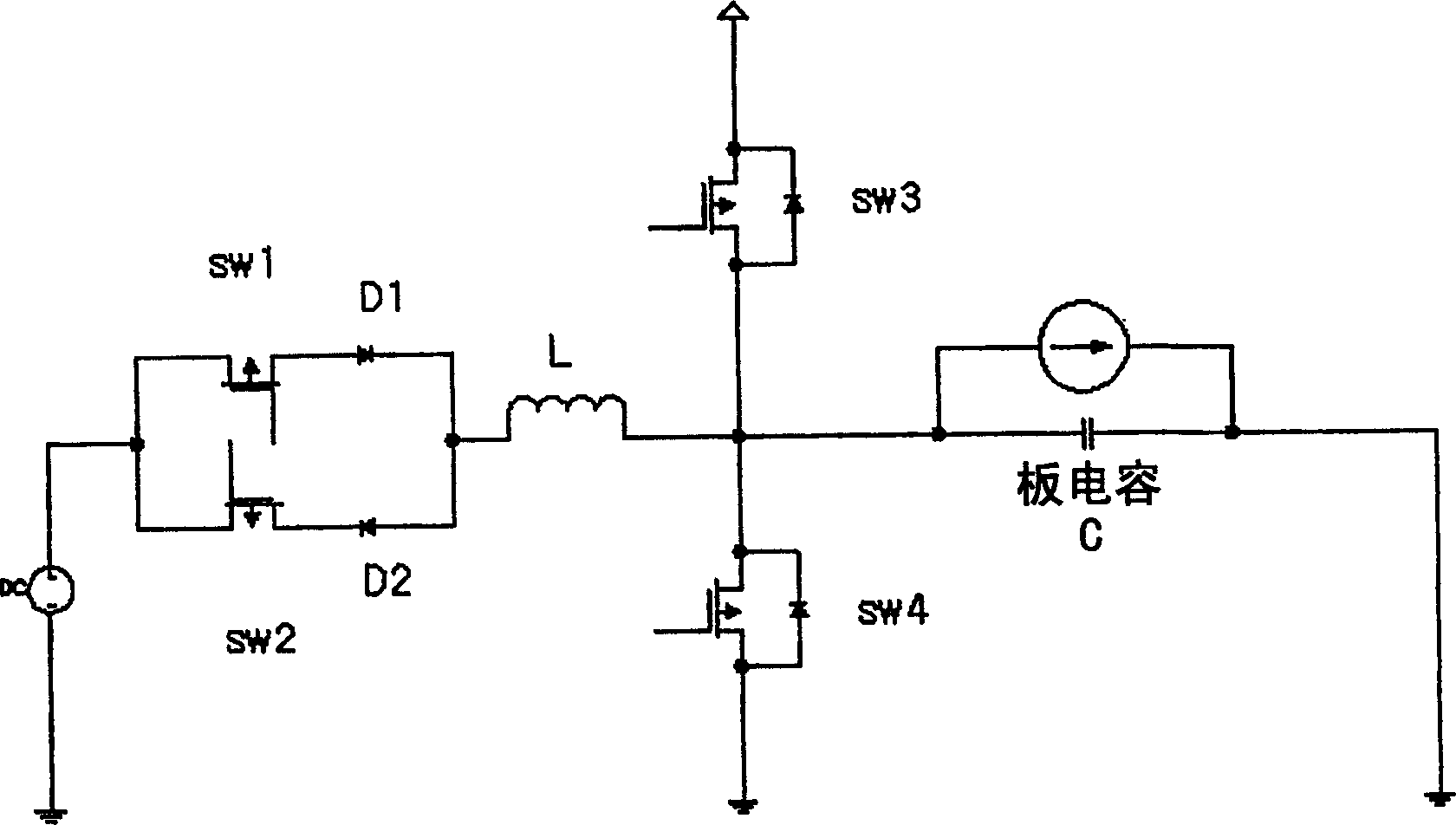

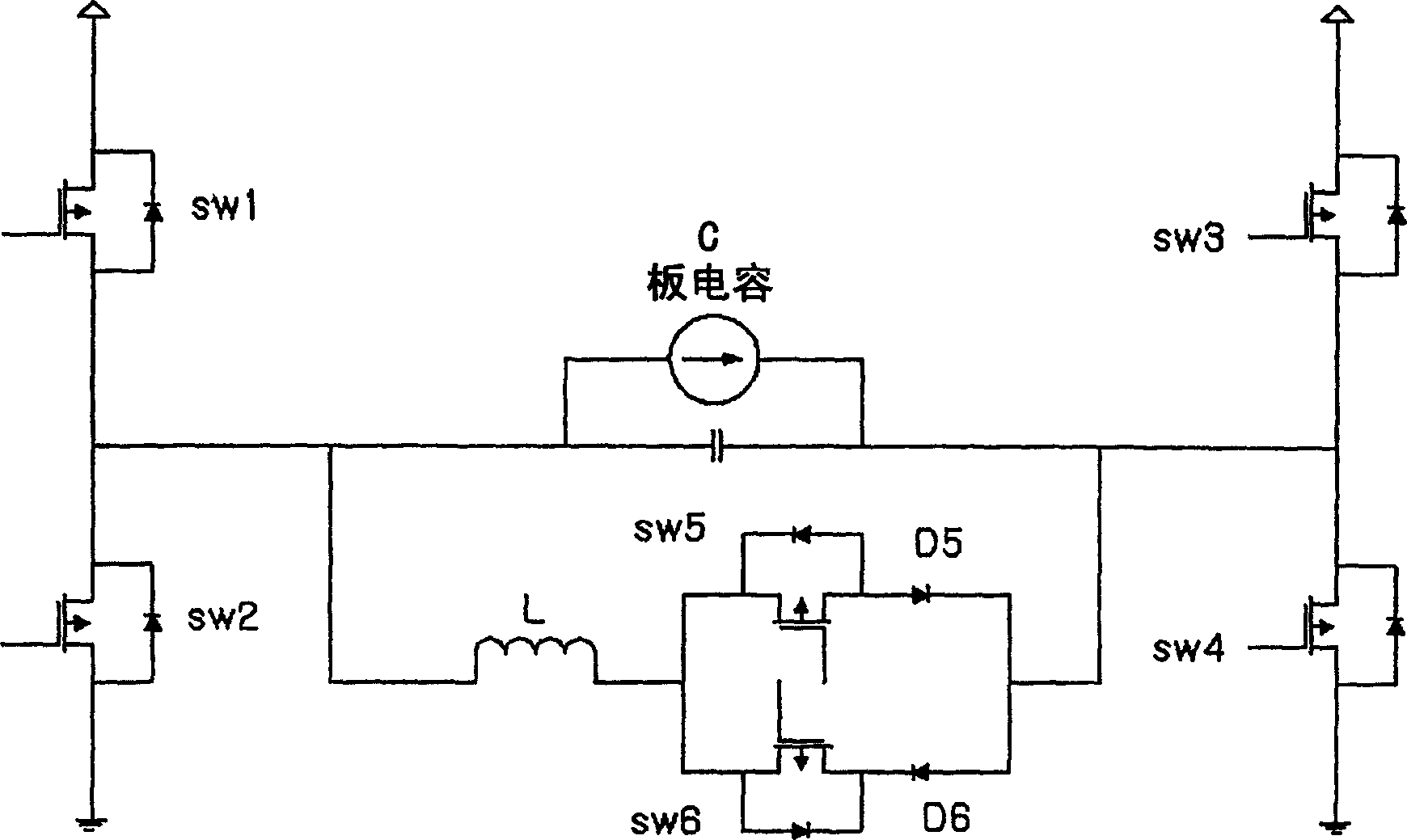

Driving circuit for energy recovery in plasma display panel

A technology for energy recovery and driving circuits, applied in static indicators, irreversible DC power input conversion to AC power output, instruments, etc., can solve the problem of complex circuit control, voltage can not increase input voltage, and difficult to control board capacitance. Sudden changes in terminal voltage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In the energy recovery driving circuit according to the first embodiment of the present invention, the primary coil is connected between the resonance inductor and the load, the first switching device is connected between the power supply voltage and the resonance inductor, and the second switching device connected between the resonant inductor and ground; and the energy recovery unit further includes first and second diodes for conducting current in the direction of the voltage source. The secondary coil includes: a first secondary coil, connected in series with a first diode between the supply voltage and ground, and coupled to the primary coil so that charging current flows through the voltage source when the charging current flows through the primary coil and a second secondary coil connected in series with the second diode between the supply voltage and ground and coupled to the primary coil so that the discharge current flows into the voltage source when the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com