Flexible injection anchor rod

A bolt and flexible technology, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., to achieve the effects of easy recycling, safe and reliable anchor protection, and simplified construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] (1) The implementation process of flexible injection pressure bolt installation with rigid injection check valve

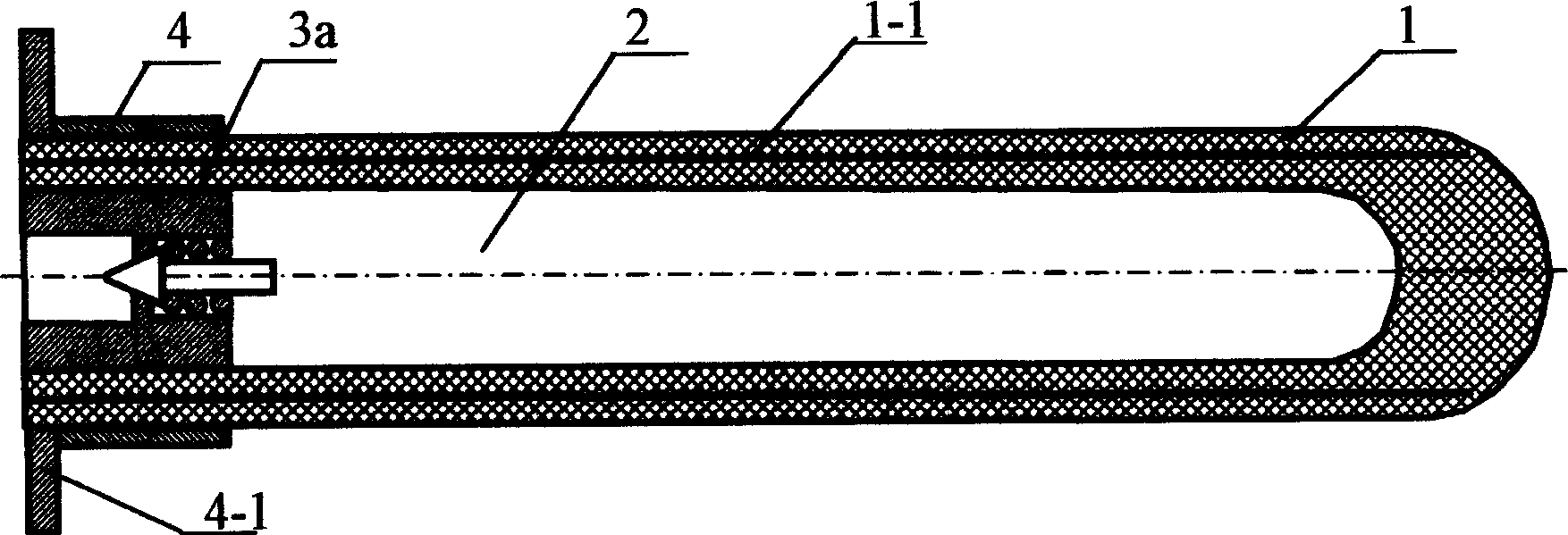

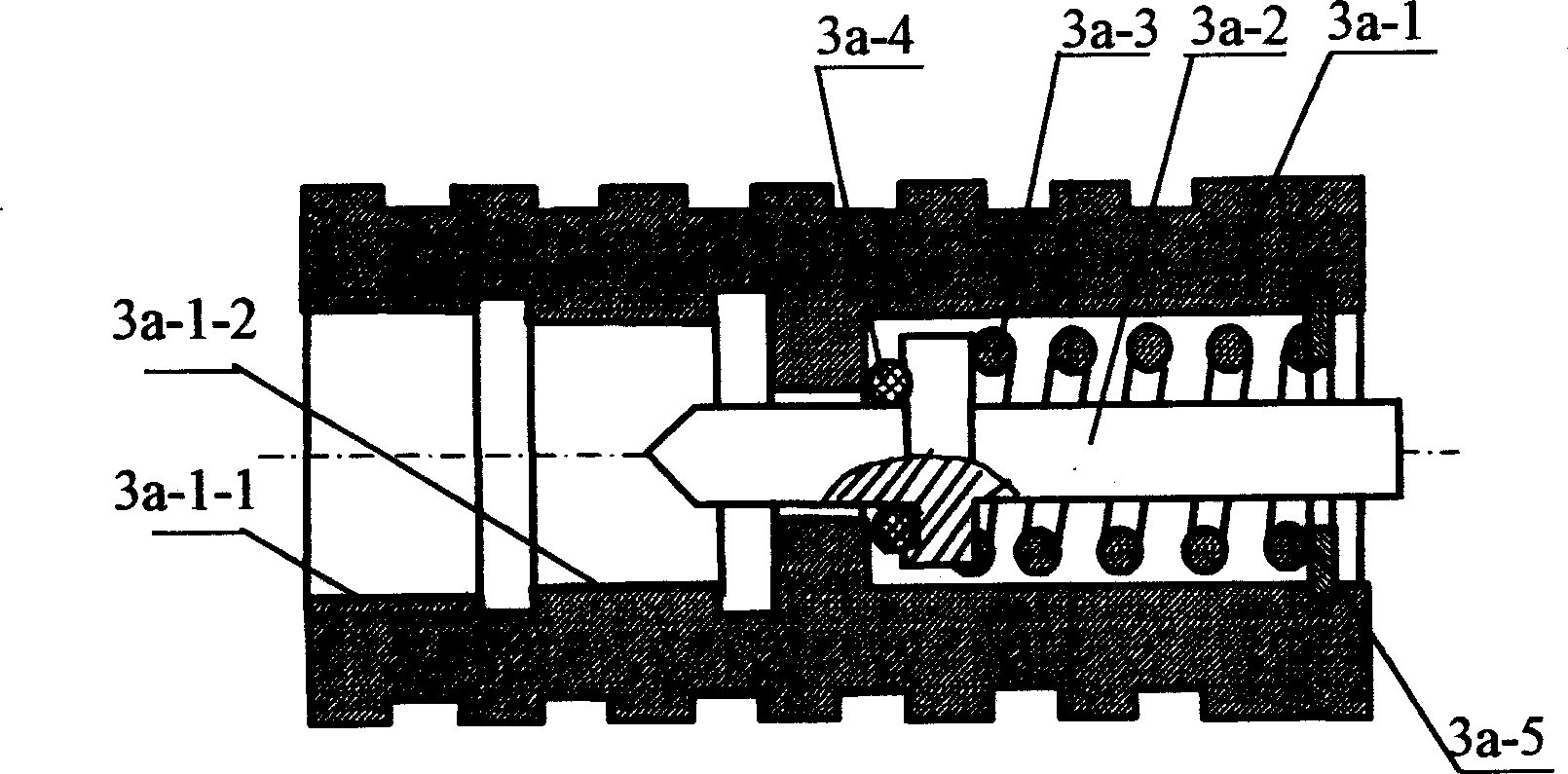

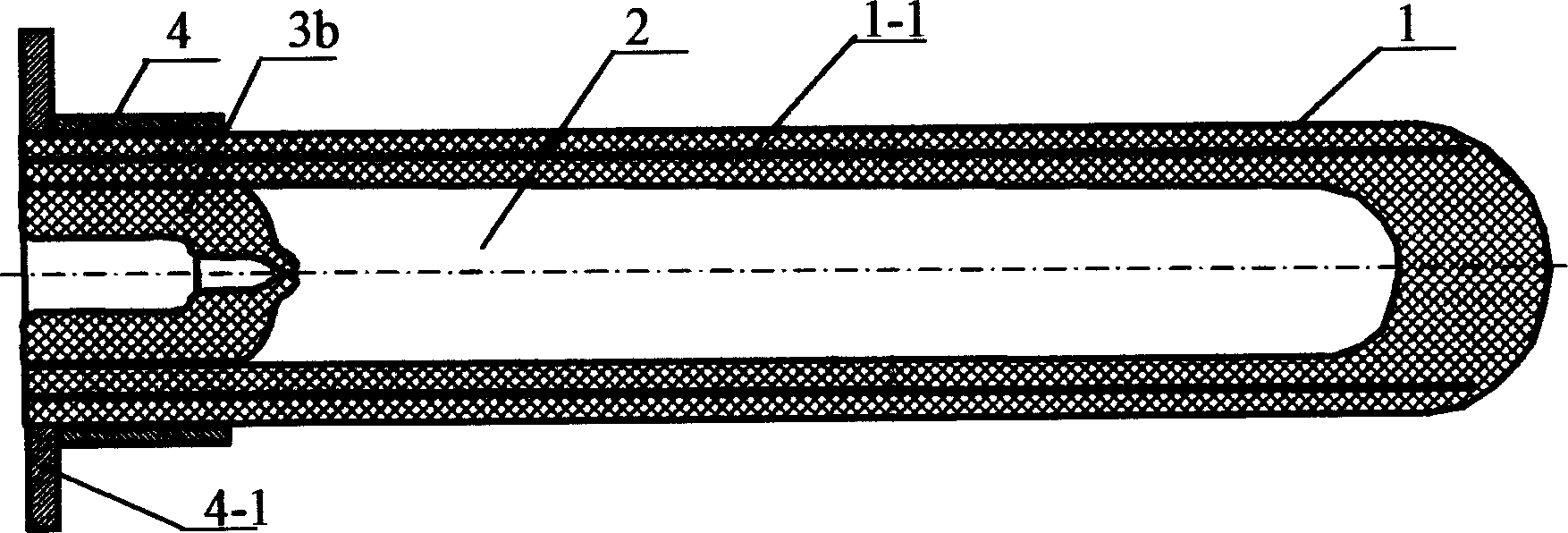

[0026] The anchor body 1 of the flexible injection anchor installed with a rigid injection one-way valve is made of high-elastic polyurethane, which is cast or extruded, or rubber material is molded, and the surface is specially treated with steel wire or fiber material. Composite reinforced processing. When casting with polyurethane material, the casting mold should be processed according to the shape shown in Figure 1 before pouring. The female mold of the mold adopts an openable double-split structure, and the two ends of the female mold are provided with reinforced composite steel wire positioning holes or fiber material tensioning holes. , to facilitate the positioning of composite reinforced steel wires or fibers; after pouring, pull out the core mold (male mold) and open the female mold to form. When the polyurethane material is used for extrusion m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com