Reverse pedaling and accelerating mechanism for bicycle

The technology of a speed-increasing mechanism and a bicycle is applied in the direction of vehicle gearbox, vehicle parts, wheel transmission device, etc., which can solve the problems of operation failure and inability to change gears, and achieve the effects of low cost, convenient manufacture and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

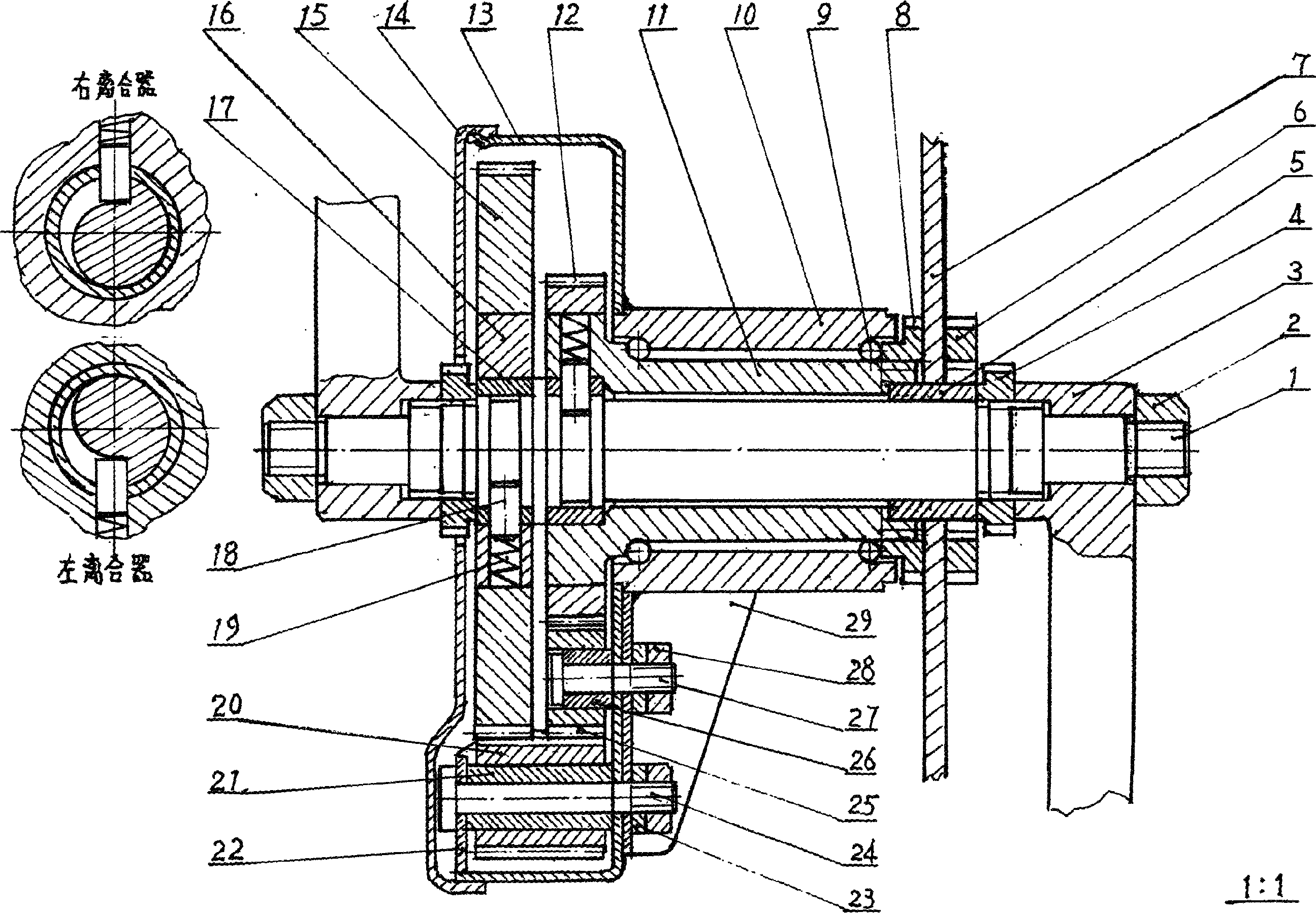

[0011] As shown in the figure, the whole mechanism is assembled in a circular gearbox composed of parts 13, 14, 22, 29 welded on the left side of part 10.

[0012] When the part 1 rotates forward, the part 18 of the right clutch drives the part 11 to rotate forward synchronously, and the part 7 (large sprocket) fixed on the part 11 also rotates together, so that the rear wheel of the bicycle is driven to rotate through the chain to make the vehicle move forward , which is the same as riding a bicycle normally, which is a speed. At the same time, the part 11 reverses the part 25 meshed with it, makes the part 20 meshed with the part 25 forward, and makes the part 16 meshed with the part 20 (that is, the bull gear) reverse. Because part 1 rotates forward and part 16 reverses, so the left clutch formed by part 16 and part 1 is in an overrunning state, and part 16 is in a no-load idling state.

[0013] When the part 1 reverses, the part 18 in the left clutch drives the part 16 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com