Process for stepped quenching by high pressure gas

A high-pressure gas, graded quenching technology, applied in the field of heat treatment, can solve problems such as unenvironmental protection, and achieve the effect of reducing heat treatment deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

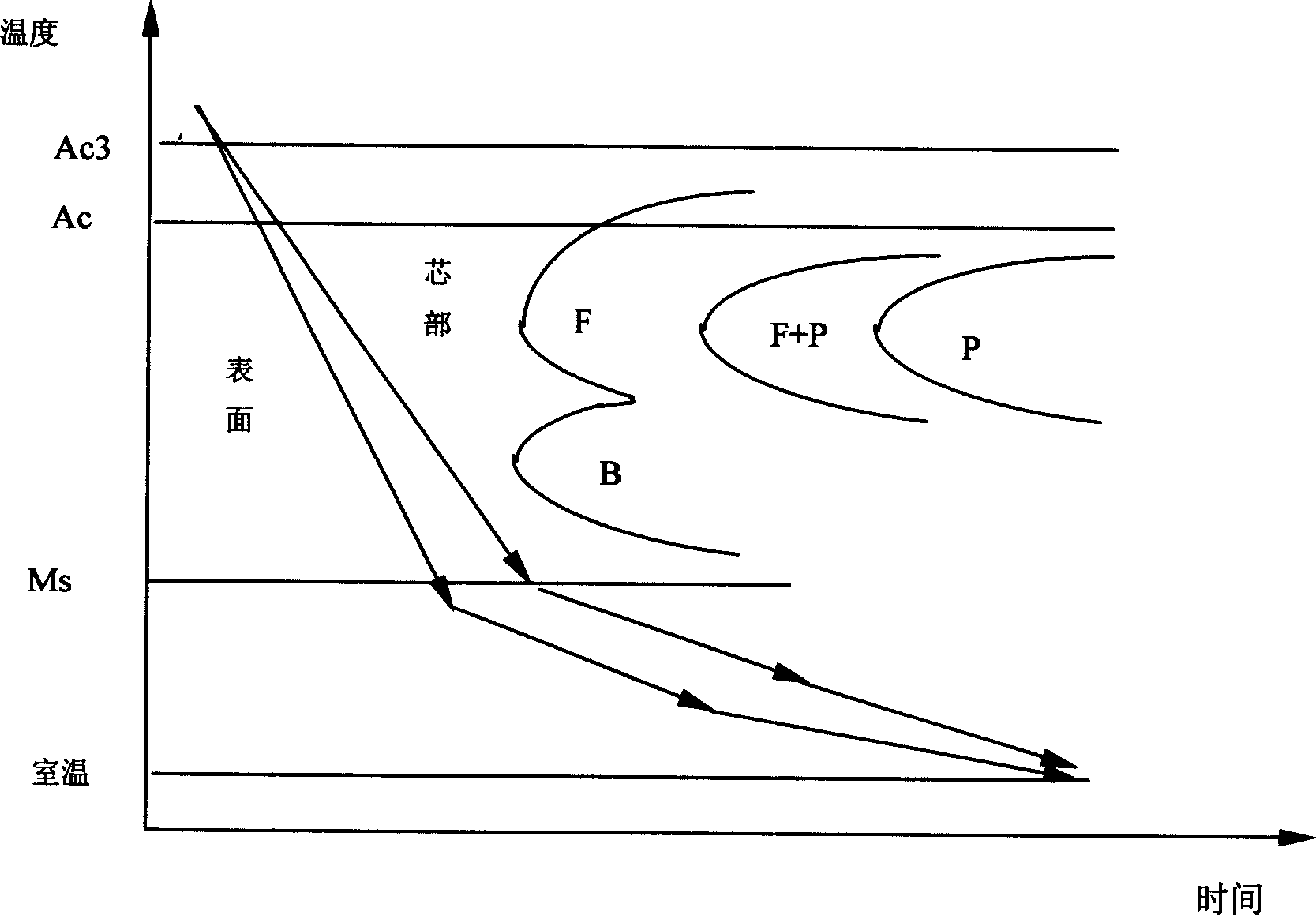

Method used

Image

Examples

Embodiment 1

[0015] A car automatic transmission parts, using N 2 As a quenching medium, the specific implementation process is as follows:

[0016] (1) At the beginning of quenching, 100% gas pressure is 20Bar;

[0017] (2) In the quenching and cooling stage, the gas pressure is reduced to 12Bar within 2-3 seconds and kept for 4 minutes;

[0018] (3) The gas pressure drops to 7Bar within 2-3 seconds and keeps for 4 minutes;

[0019] (4) The gas pressure drops to 1 Bar (atmospheric pressure level).

[0020] Implementation Effect:

[0021] The deformation results obtained by conventional controlled atmosphere heat treatment and the method of the present invention are compared in the following table: without using gas stage quenching technology, the deformation is basically similar to that of conventional controlled atmosphere heat treatment, but the deformation is significantly reduced by using gas stage quenching technology.

[0022] High pressure gas non-stage quenching hea...

Embodiment 2

[0024] The planetary gear parts of an automobile automatic transmission are made of SAE 4615, and the high-pressure gas staged quenching process is adopted. The specific implementation process is as follows:

[0025] (1) At the beginning of quenching, 100% gas pressure is 14Bar;

[0026] (2) In the quenching and cooling stage, the gas pressure is reduced to 8Bar within 2-3 seconds and kept for 4 minutes;

[0027] (3) The gas pressure drops to 5Bar within 3 seconds and keeps for 4 minutes;

[0028] (4) The gas pressure drops to 1 Bar (atmospheric pressure level).

[0029] After adopting the present invention, the heat treatment structure and performance meet the technical requirements of the product, more than 95% of the core structure of the gear is low-carbon martensite, and the permeated layer structure is high-carbon cryptoneedle martensite and retained austenite and dispersed distribution The carbides meet the requirements of relevant national and international heat trea...

Embodiment 3

[0031] The gear gear of an automobile manual transmission is made of SAE 5015. Due to the influence of the gear structure, in the conventional controlled atmosphere heat treatment process, the splines of the parts are generally easy to form a taper of about 0.03-0.07mm after heat treatment. The hole is easy to form a taper of 0.05 ~ 0.10mm.

[0032] After adopting high-pressure gas graded quenching technology, the specific implementation process is as follows:

[0033] (1) At the beginning of quenching, 100% gas pressure is 18Bar;

[0034] (2) In the quenching and cooling stage, the gas pressure is reduced to 12 Bar within 2 seconds and kept for 4 minutes;

[0035] (3) The gas pressure drops to 6Bar within 3 seconds and keeps for 4 minutes;

[0036] (4) The gas pressure drops to 1 Bar (atmospheric pressure level).

[0037] After adopting the invention, the structure and performance of the heat treatment meet the technical requirements of the product. Taper can be reduced t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com