Boiling heat-transfer tube and making method thereof

A manufacturing method and technology for heat transfer tubes, which are used in heat transfer modification, refrigerators, tubular elements, etc., can solve the problems of inability to exert performance and poor wettability of refrigerant liquid, and achieve the promotion of boiling and good heat transfer. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

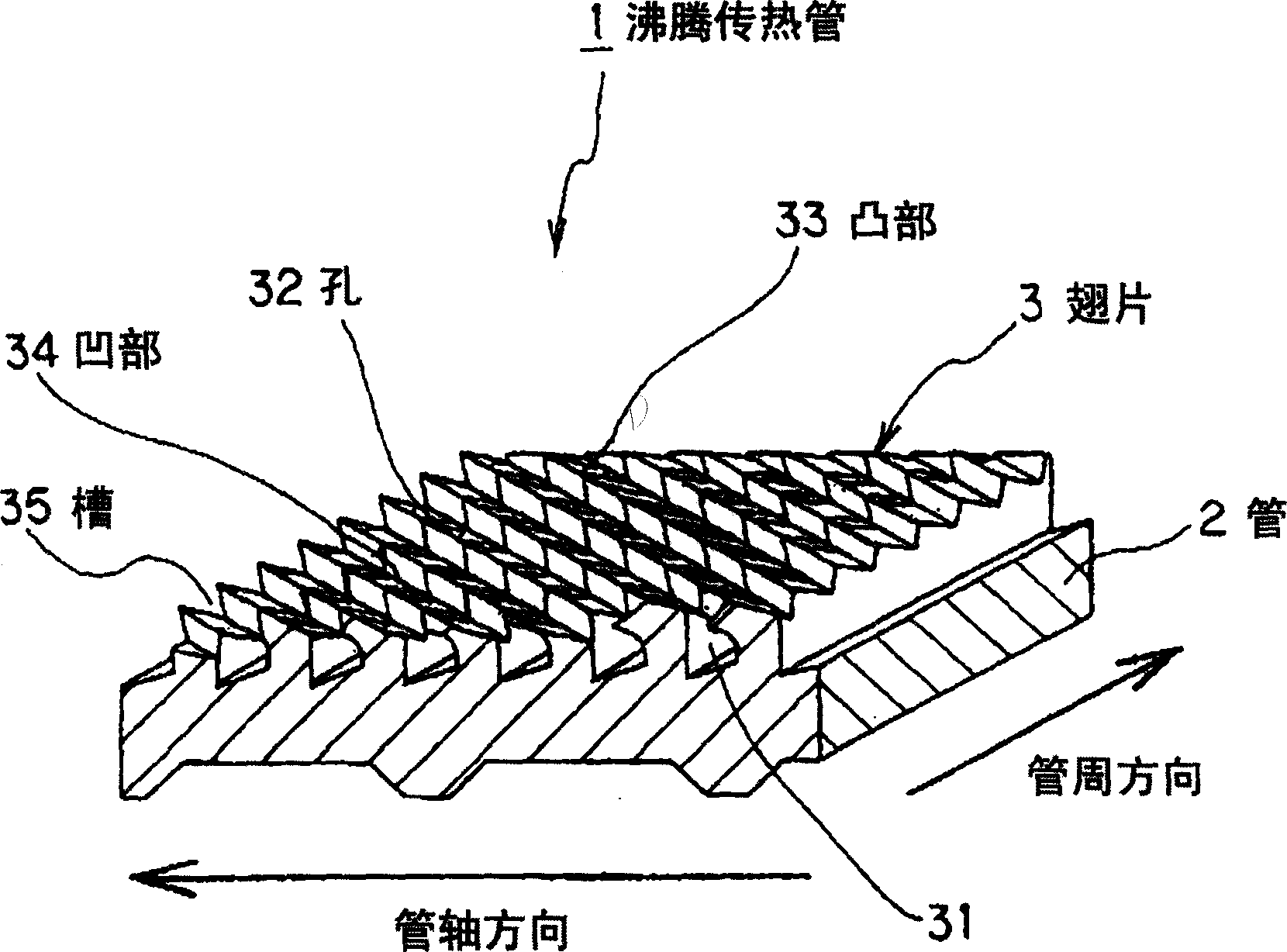

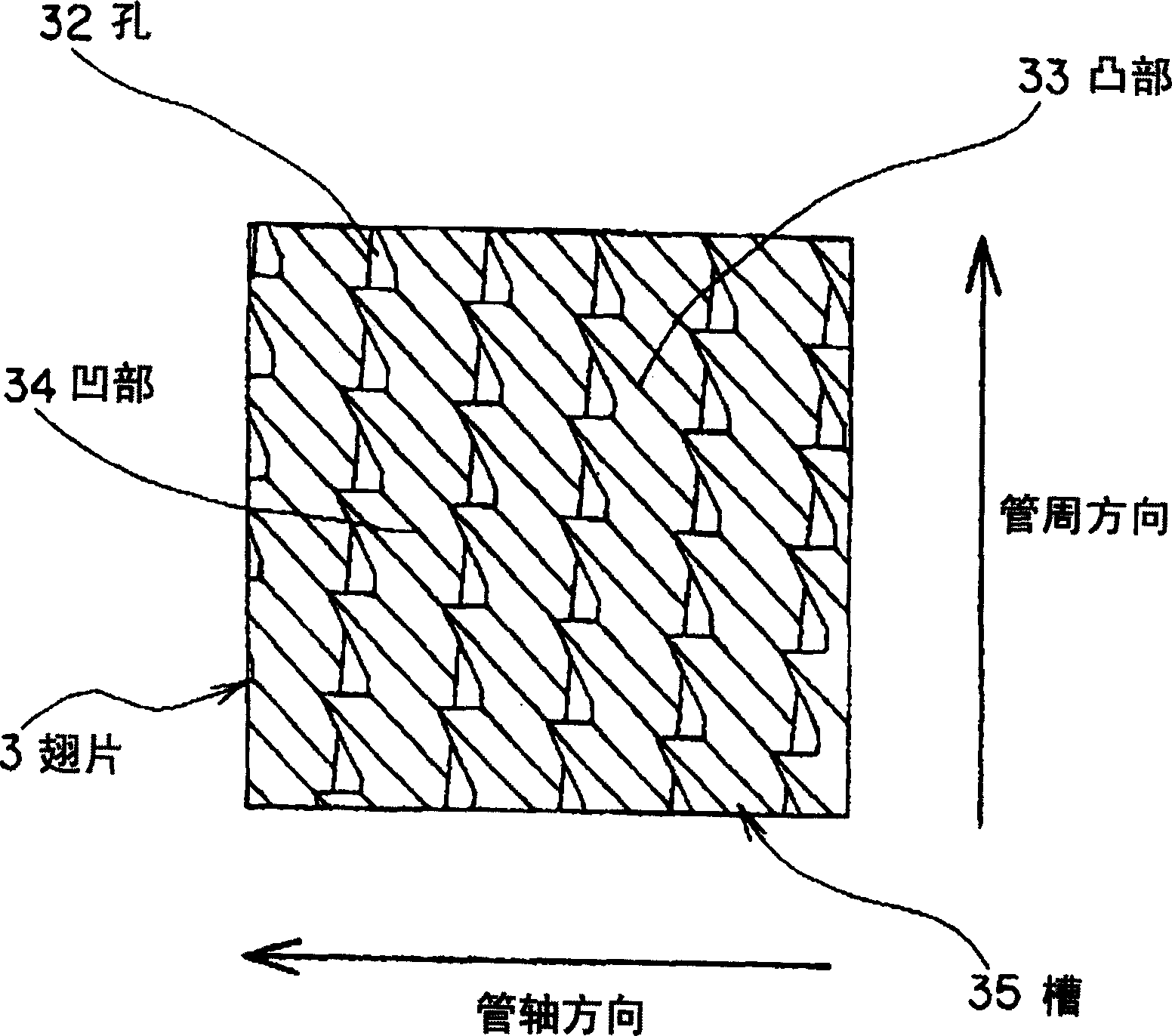

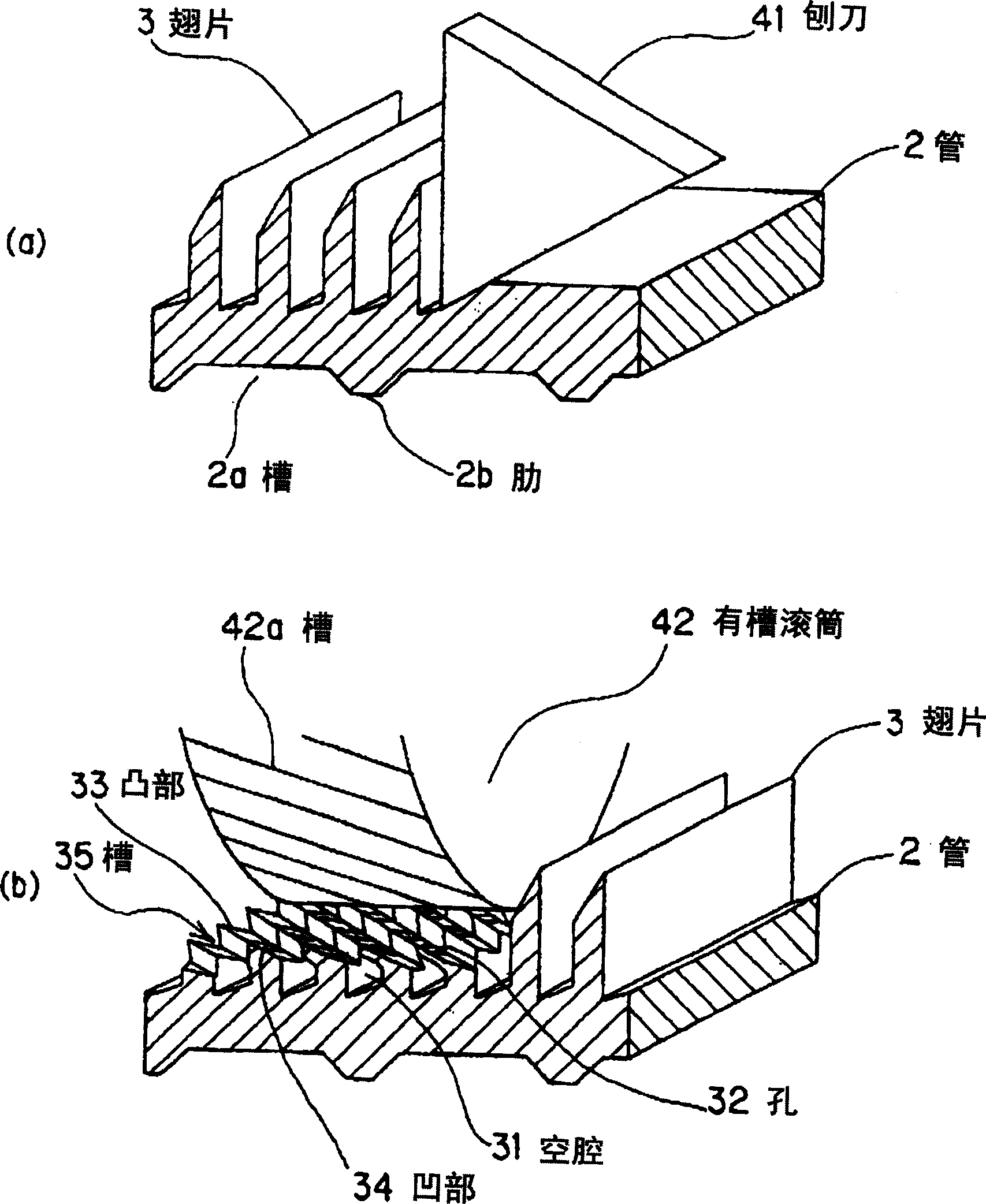

[0022] figure 1 and figure 2 Shown is the boiling heat transfer tube of the embodiment of the present invention. The boiling heat transfer tube 1 structurally includes a tube 2 made of metal tubes such as copper, copper alloy, aluminum, etc. with excellent heat transfer performance, and fins 3 scooped near the surface of the tube 2 with a processing tool such as a planer.

[0023] The fin 3 has a spiral or annular cavity 31 formed in the circumferential direction of the tube 2 and holes 32 for communicating the cavity 31 with the outside (refrigerant liquid) at predetermined intervals. The surface of the fin 3 is a concavo-convex surface in which a convex portion 33 and a concave portion 34 are sequentially formed between the holes 32 , and one side of the convex portion 33 is provided as an inclined surface.

[0024] The cavity 31 is continuous in the circumferential direction of the tube, and is perpendicular to or inclined to the tube axis. The groove 35 formed by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com