Coaxial measuring tool and measuring method

A technology for measuring tooling and measuring methods, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as unfavorable market competition, high labor intensity, shipowner disputes, etc., to achieve favorable market competition, reduce labor intensity, and satisfy users. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

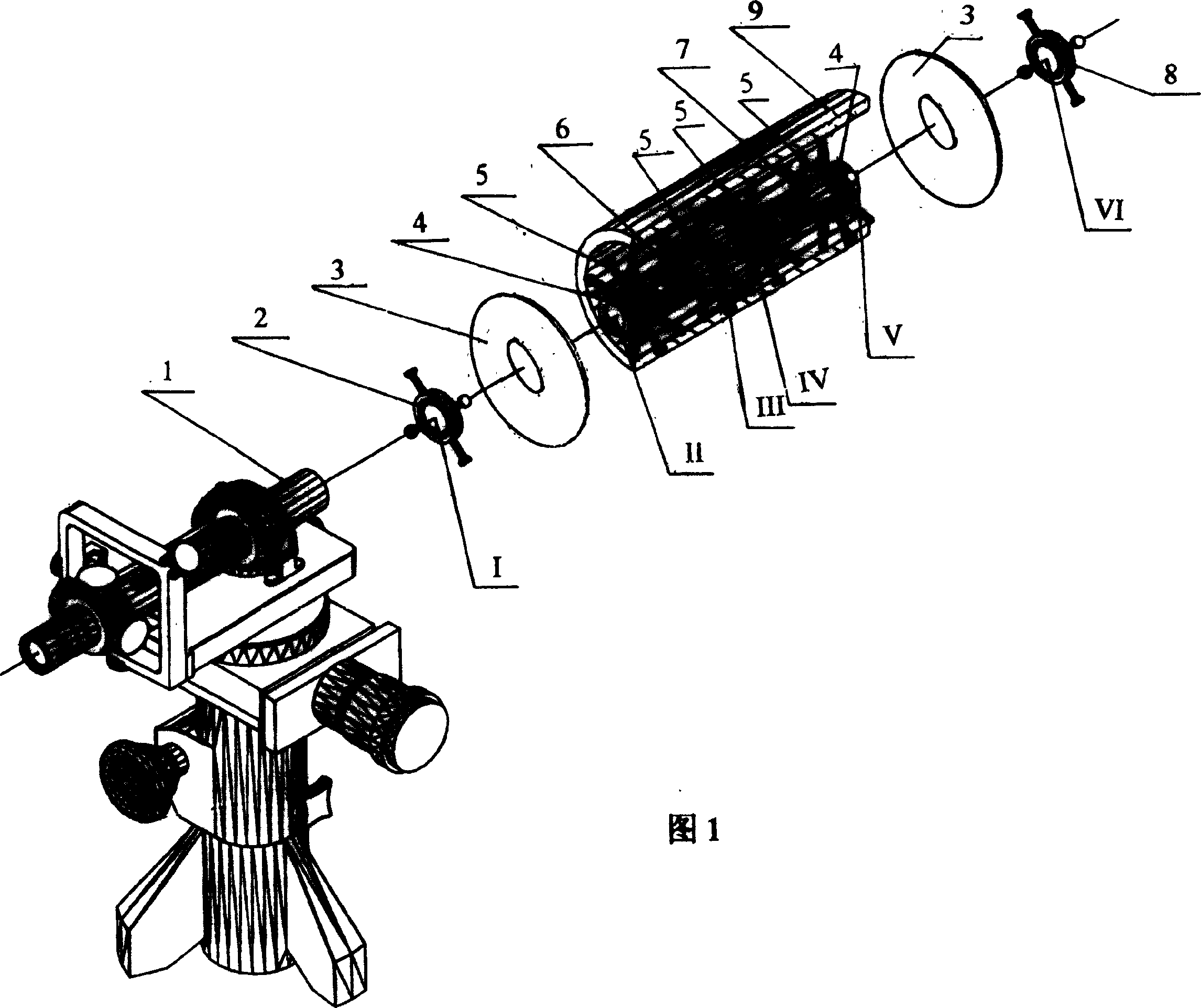

[0026] Coaxiality measurement tooling and measurement method, measuring instruments include micro-collimation telescope 1 and its accessories, accessories include Φ57.14mm, height 20mm, precision 2" optical target, bracket for erecting micro-collimation telescope, horizontal Bracket and special lighting source.

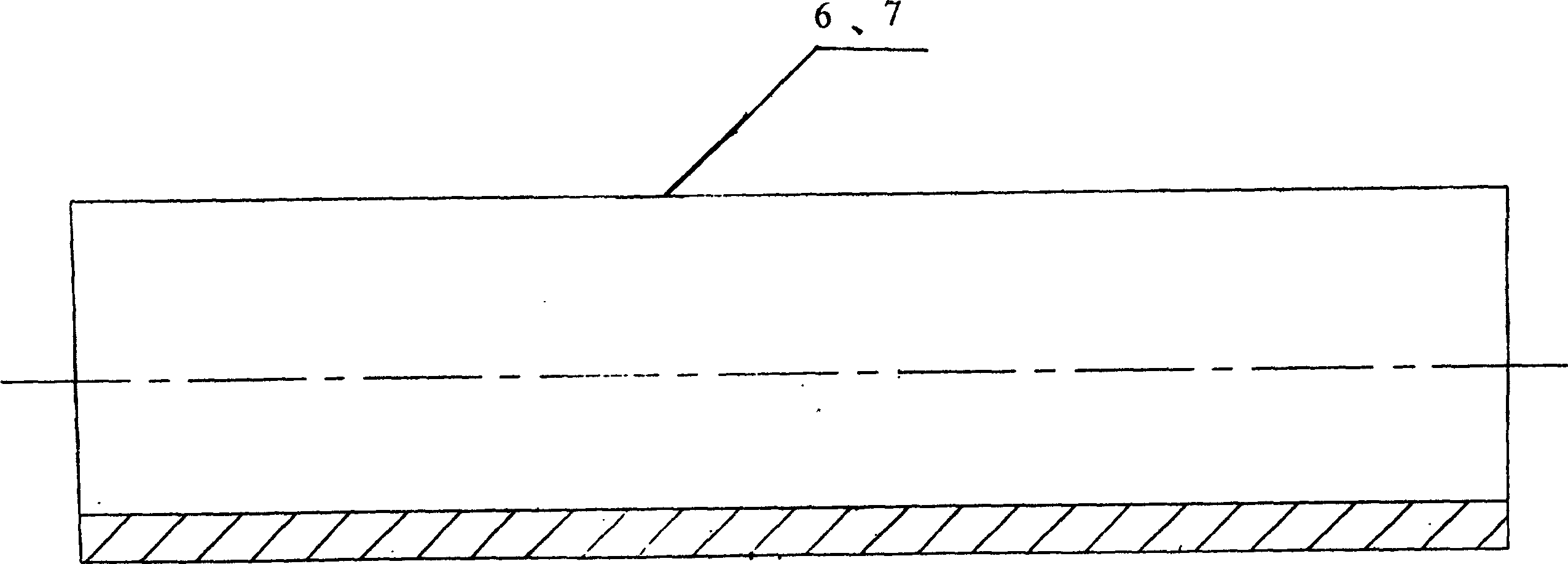

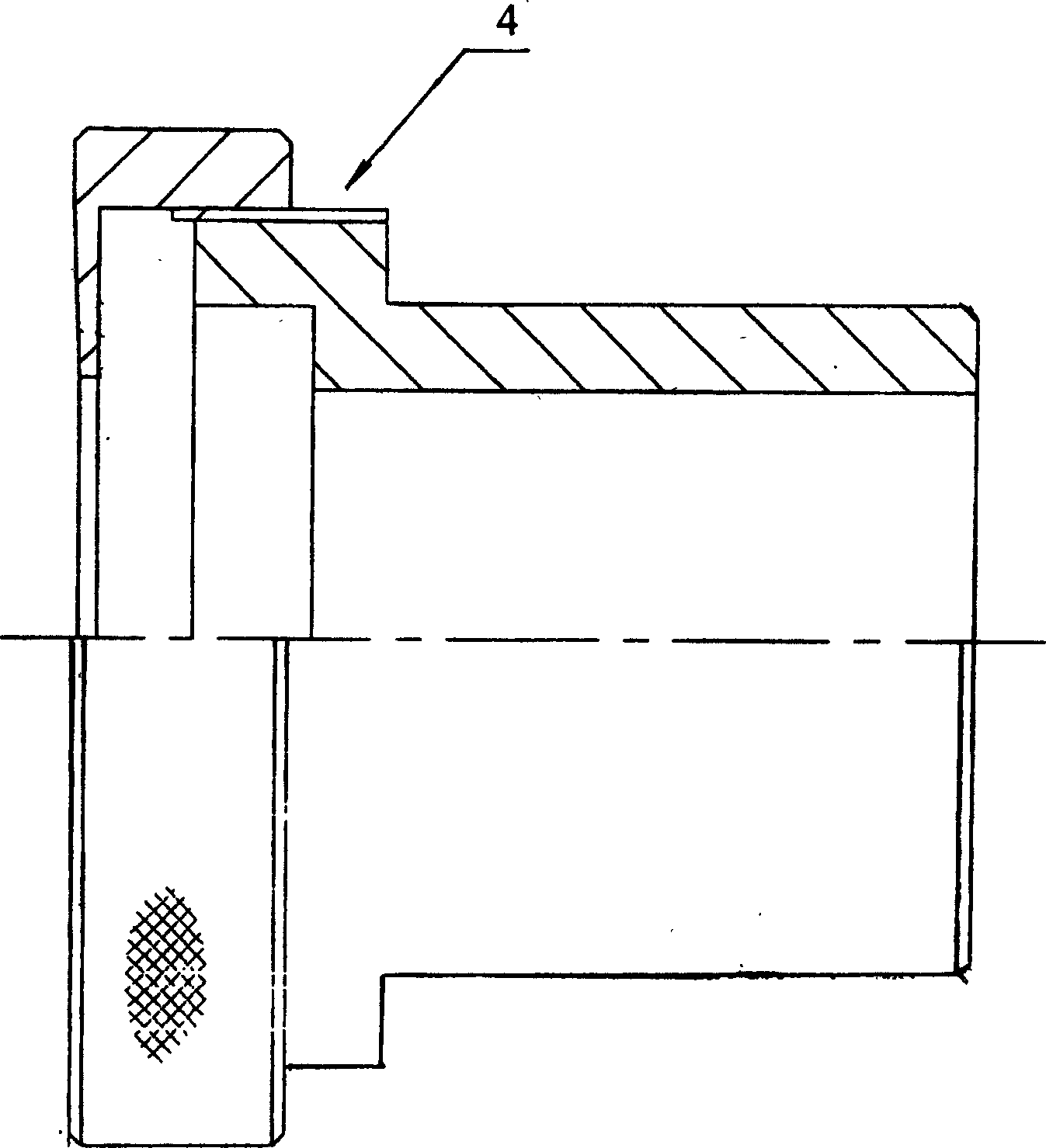

[0027] Coaxiality measurement tooling, including stern light tube 6, bow light tube 7, light target 4, light target bracket 5, stern base point target piece bracket 2, bow base point target piece bracket 8, special inner micrometer positioning shaft 13 and Axis positioning datum tooling 3. The light pipe 6 at the stern end and the light pipe 7 at the bow end have the same structure, and the target plate support 2 at the stern base point and the target plate support 8 at the bow base point have the same structure. Before the measurement, the two optical targets 4 are equipped with optical target sheets in the instrument accessories and calibrated on the 0-level V-type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com