Pipe node welding sean ultrasonic detecting machine scanning device

A technology of ultrasonic testing and mechanical scanning, applied in measuring devices, analyzing solids using sonic/ultrasonic/infrasonic waves, and using sonic/ultrasonic/infrasonic waves for material analysis, etc., can solve problems such as low degree of automation, many human factors, and no records , to achieve accurate positioning, improve detection efficiency and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

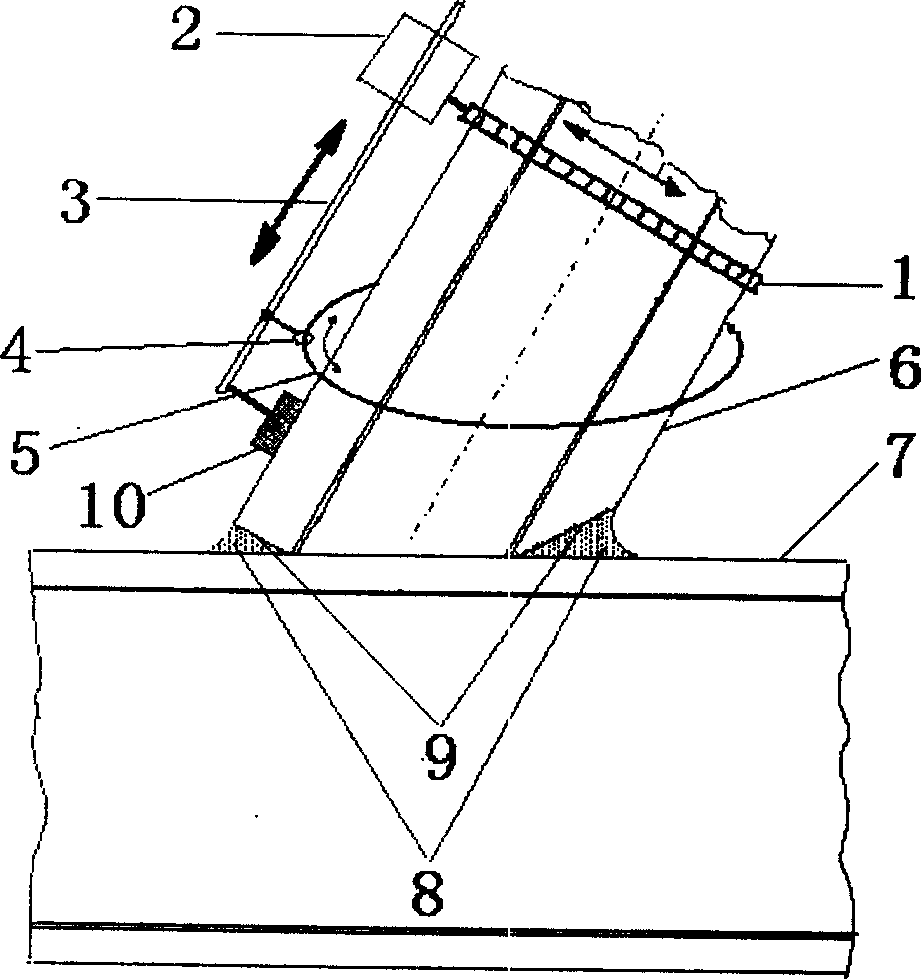

[0016] according to figure 1 It can be seen that the device is composed of a scanning guide rail 1, a stepping motor 2, a sliding rod 3, a sliding ring 4, and a probe positioning ring 5, and is characterized in that:

[0017] The weld groove 9 is a cut surface of the TKY branch pipe 6, and the weld 8 is formed between the weld groove 9 and the main pipe 7 through the filling of solder, so that the TKY pipe branch 6 is firmly welded on the TKY main pipe 7 to reinforce the The steel jacket structure composed of main pipes, TKY branch pipe 6, TKY main pipe 7 and weld 8 form a typical Y-shaped pipe joint, which is the workpiece to be inspected, and weld 8 is the Y-shaped pipe joint to be inspected position; the ultrasonic probe 10 is an ultrasonic transmitting and receiving device, installed on the sliding rod 3, and its acoustic radiation surface is directly in contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com