Charging unit for image forming apparatus

一种充电部件、充电设备的技术,应用在电气元件、应用电荷图形的电记录工艺、电晕放电装置等方向,能够解决电阻分布不均匀、感光部件表面电位分布不均匀等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

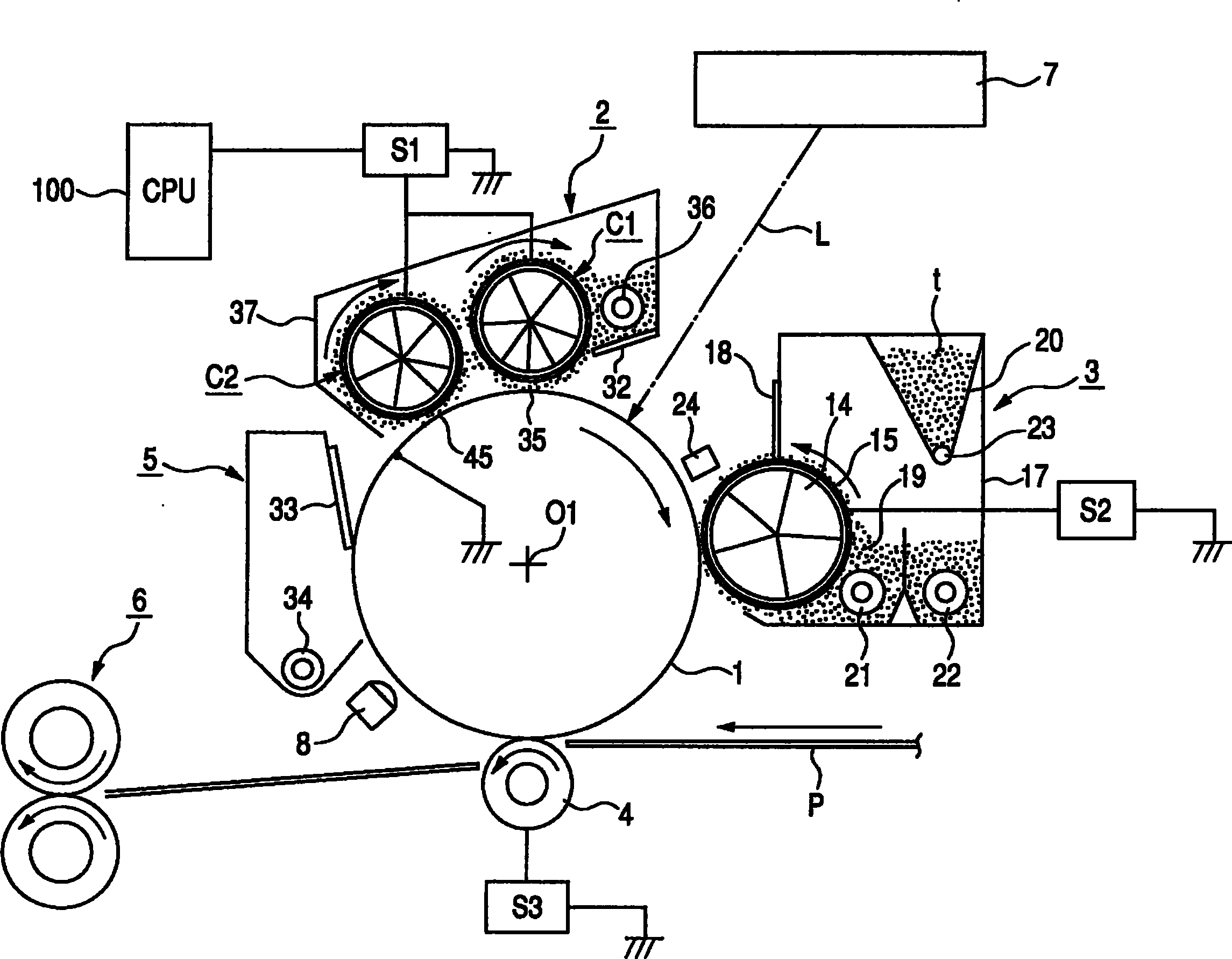

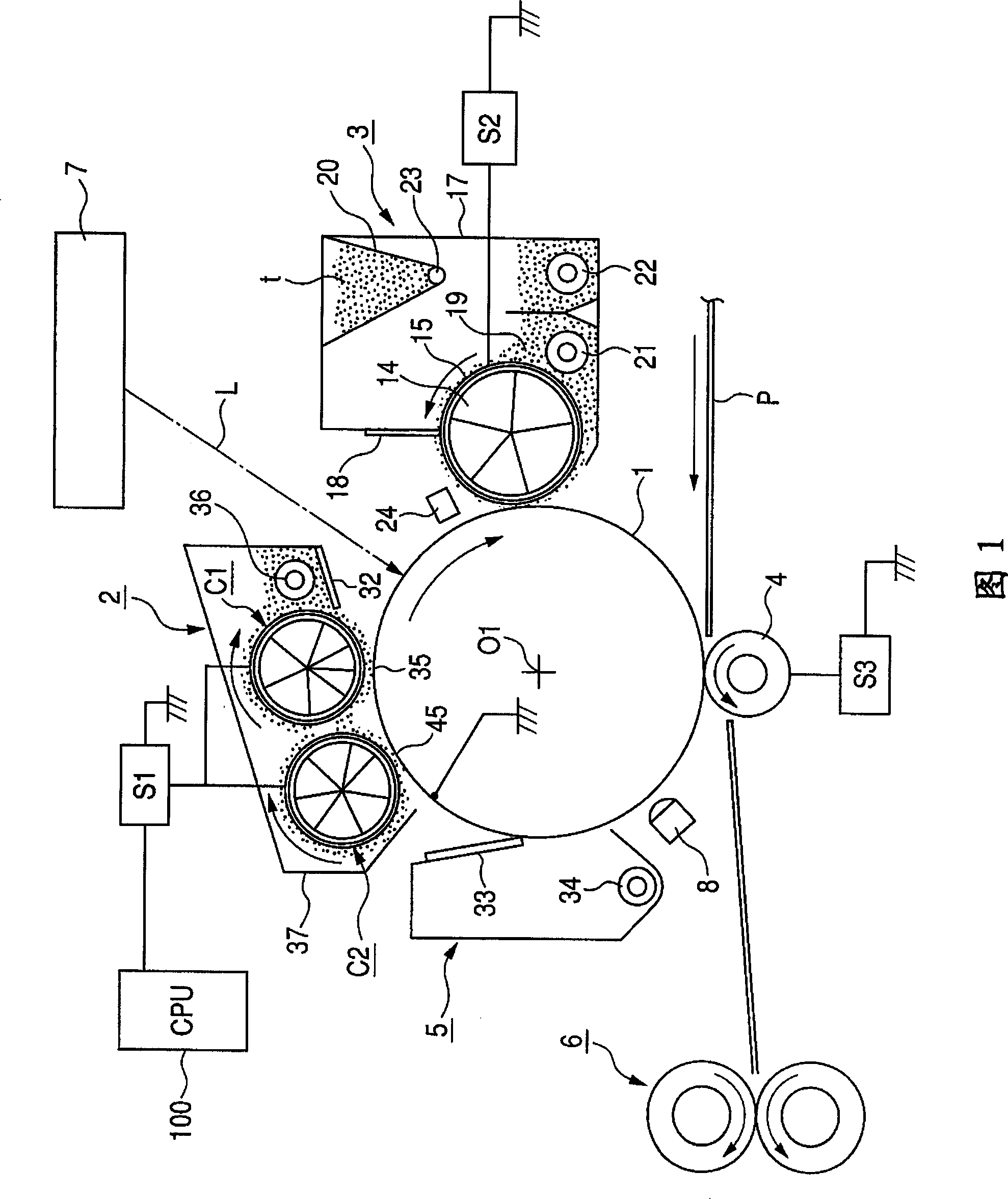

[0035] Fig. 1 outlines the structure of the image forming apparatus of Example 1 schematically.

[0036] (1) The overall structure of the imaging device

[0037] The image forming apparatus of the present invention is a laser beam printer having a plurality of magnetic brush charging devices for transfer electrophotographic processing.

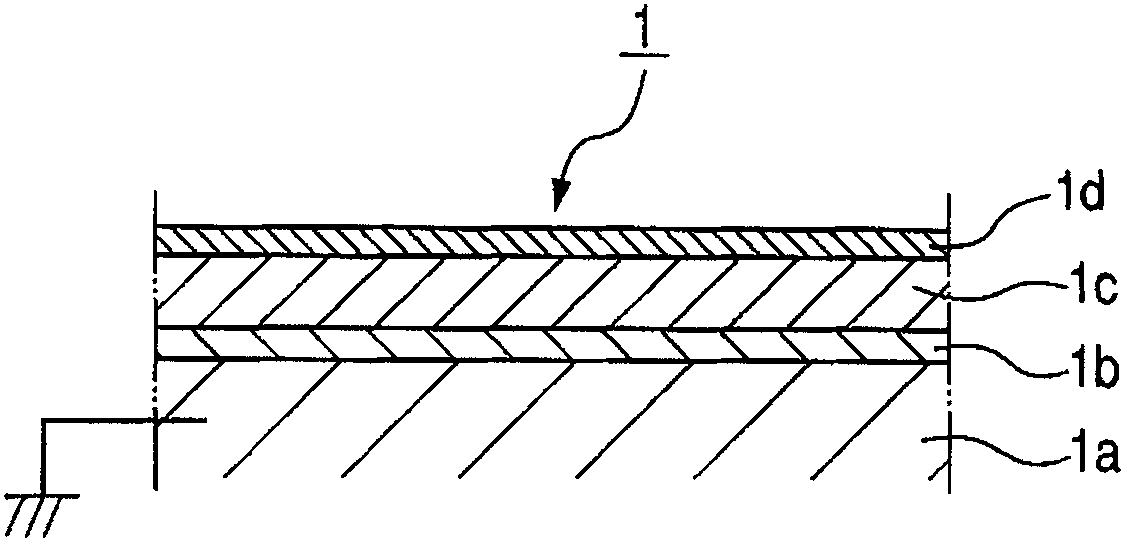

[0038] In FIG. 1 , a rotary drum-type electrophotographic photosensitive member 1 (hereinafter referred to as a photosensitive drum 1 ) as an image bearing member is driven so as to rotate clockwise in the direction of an arrow at a prescribed peripheral speed. The photosensitive drum 1 in Example 1 was made of amorphous silicon (a-Si).

[0039] The multi-magnetic brush charging unit 2 serves as a charging device having a plurality of magnetic brush charging devices. It uniformly charges the surface of the rotary photosensitive drum 1 with a specified potential of a specified polarity (-700 V in Example 1). The magnetic brush charging unit ...

example 2

[0116] In Example 2, an organic photosensitive member was used as the photosensitive drum 1 . Other features are the same as those of the device in Example 1, and the details will not be repeated.

[0117] The photosensitive drum 1 in Example 2 as an image bearing member was manufactured using a negatively chargeable OPC photosensitive member. It has a layered structure comprising a grounded aluminum drum base 1a (30 mm in diameter) on which first to fifth functional layers 1e to 1i are sequentially coated, as shown in FIG. 5 .

[0118] The first layer 1e supported by the drum base 1a is an undercoat layer with a thickness of about 20 [mu]m for smoothing defects etc. on the drum base 1a and preventing moiré due to reflection of the exposure laser beam.

[0119] The second layer 1f is a positive charge injection layer for preventing the positive charges injected from the aluminum drum base 1a from canceling the negative charges on the surface of the photosensitive member. It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com