Optical fiber composite electrical power cable

一种电力电缆、光纤复合的技术,应用在电力电缆、绝缘电缆、通信电缆等方向,能够解决不能精确地测量预定区域温度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

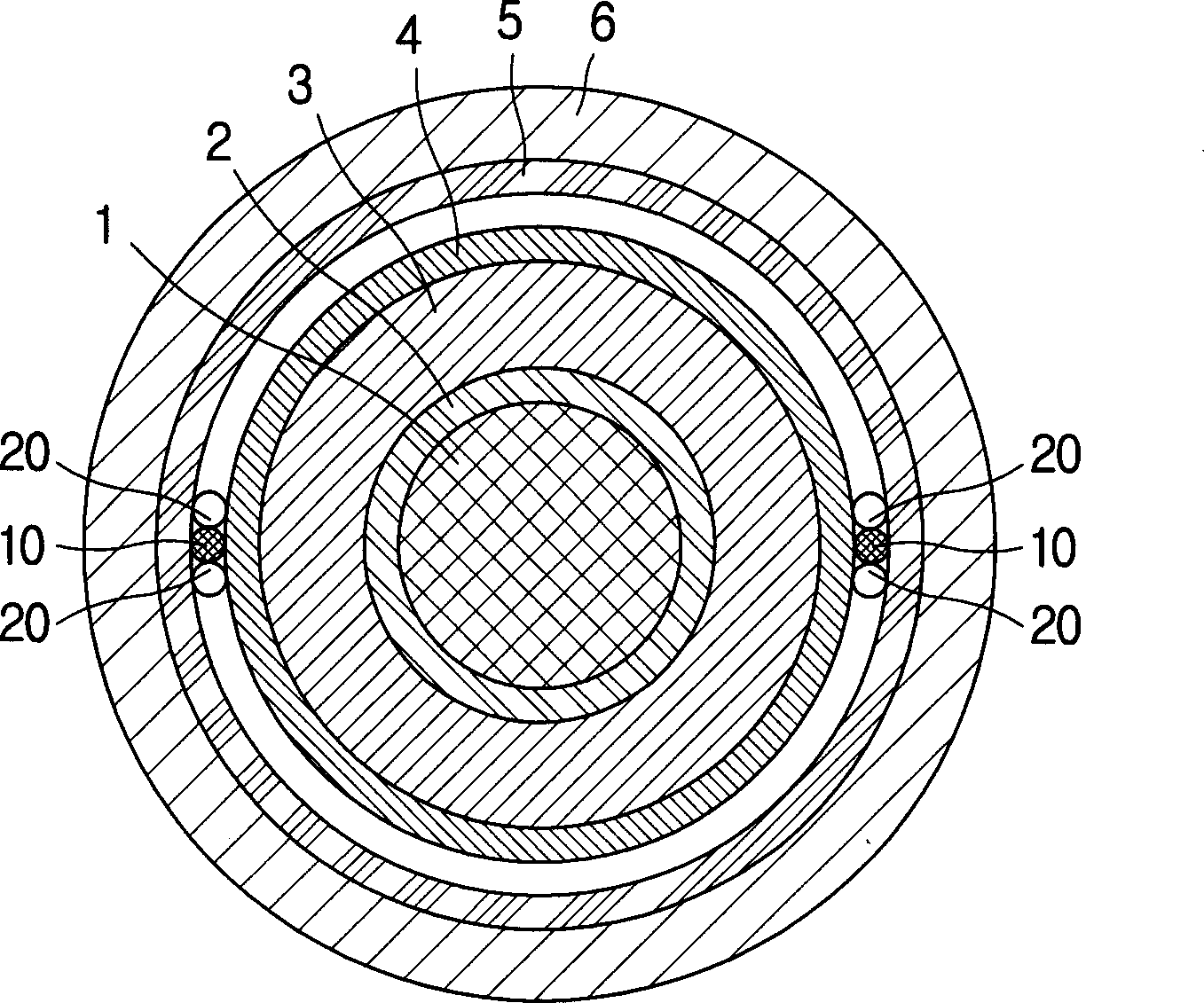

[0028] figure 1 is a sectional view showing the optical fiber composite power cable according to the first embodiment of the present invention. refer to figure 1 , the cable includes a core 1, 2, 3, and 4 located at the center of the cable, sheaths 5 and 6 covered around the core, and optical components 10 and 20 placed between the core and the sheath.

[0029] The core comprises a central conductor 1, an inner semiconducting layer 2 covering the periphery of the central conductor 1, an insulating layer 3 covering the periphery of the inner semiconducting layer 2, and an outer semiconducting layer 4 covering the periphery of the insulating layer 3 .

[0030] The central conductor 1 guides and transmits the current from the substation to the electrical equipment, and when high voltage is applied to this conductor, the semiconducting layers 2 and 4 function to prevent the accumulation of high electric fields. Furthermore, the insulating layer 3 prevents dielectric breakdown. ...

Embodiment 2

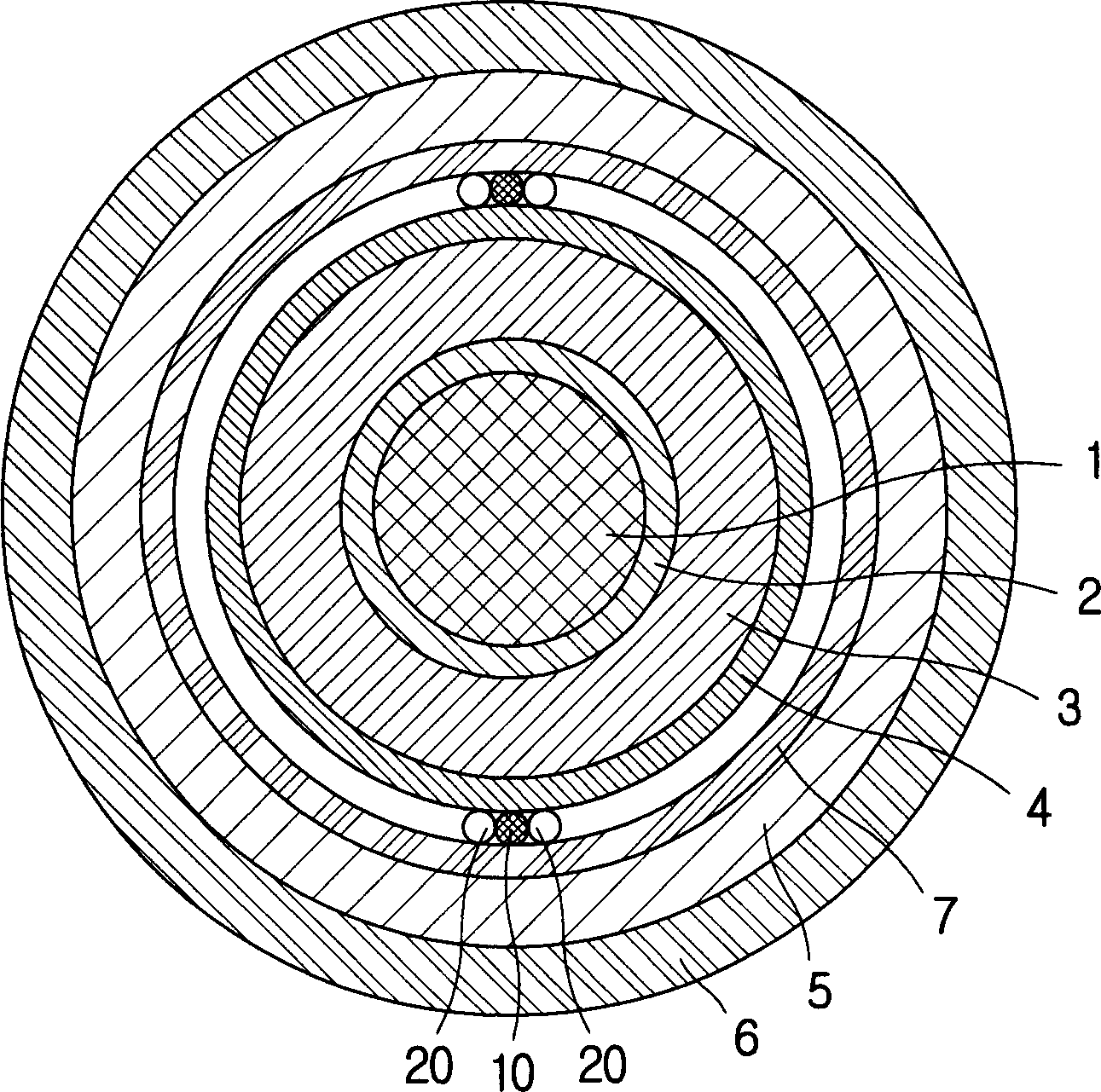

[0040] image 3 is a sectional view showing an optical fiber composite power cable according to a second embodiment of the present invention. This embodiment is similar to the previous embodiment in that the cable comprises a core 1, 2, 3 and 4, a sheath 5, 6 and 7 overlying the core, and an optical assembly 10 and 20. In particular, cores 1, 2, 3 and 4 and optical assemblies 10 and 20 do not differ in any way compared to the first embodiment. However, the detailed structure of the sheaths 5, 6 and 7 differs from the first embodiment as follows.

[0041] In addition to the metal sheath layer 5 and the protective layer 6 , the sheath of this embodiment also includes a fixing belt 7 . This fixing band 7 has the function of fixing the optical components 10 and 20 to the outer semiconducting layer 4 of the core. As for the fixing tape 7, a semiconductor tape or an insulating tape can be used. In particular, in the case where the metal sheath layer 5 is a corrugated aluminum t...

Embodiment 3

[0044] Figure 4 is a sectional view showing an optical fiber composite power cable according to a third embodiment of the present invention. This embodiment is also similar to the first embodiment, ie the cable comprises cores 1, 2, 3 and 4, jackets 6 and 8 covering the cores, and optical assemblies 10 and 20 placed between the cores and jackets. In particular, cores 1, 2, 3 and 4 and optical assemblies 10 and 20 do not differ in any way compared to the first embodiment. However, the detailed structures of the sheaths 6 and 8 are different from the first embodiment as follows.

[0045] The sheath of this embodiment comprises at least one metal wire 8 helically wound around the outer semiconductive layer 4 of the core and extending in the longitudinal direction of the cable, and a plastic protective layer 6 covering the metal wire layer 8 .

[0046] refer to Figure 4 , wires 8 made of copper or aluminum are accommodated in spaces outside the cores 1 , 2 , 3 and 4 for accom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com