Plate-to-plate connector and manufacturing method thereof

A technology of board-to-board connector and manufacturing method, which is applied in the direction of connection, fixed connection, contact parts, etc., can solve the problems of wall thickness thinning, strength, easy deformation, and insufficient production, so as to improve electrical performance and firmly hold , the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

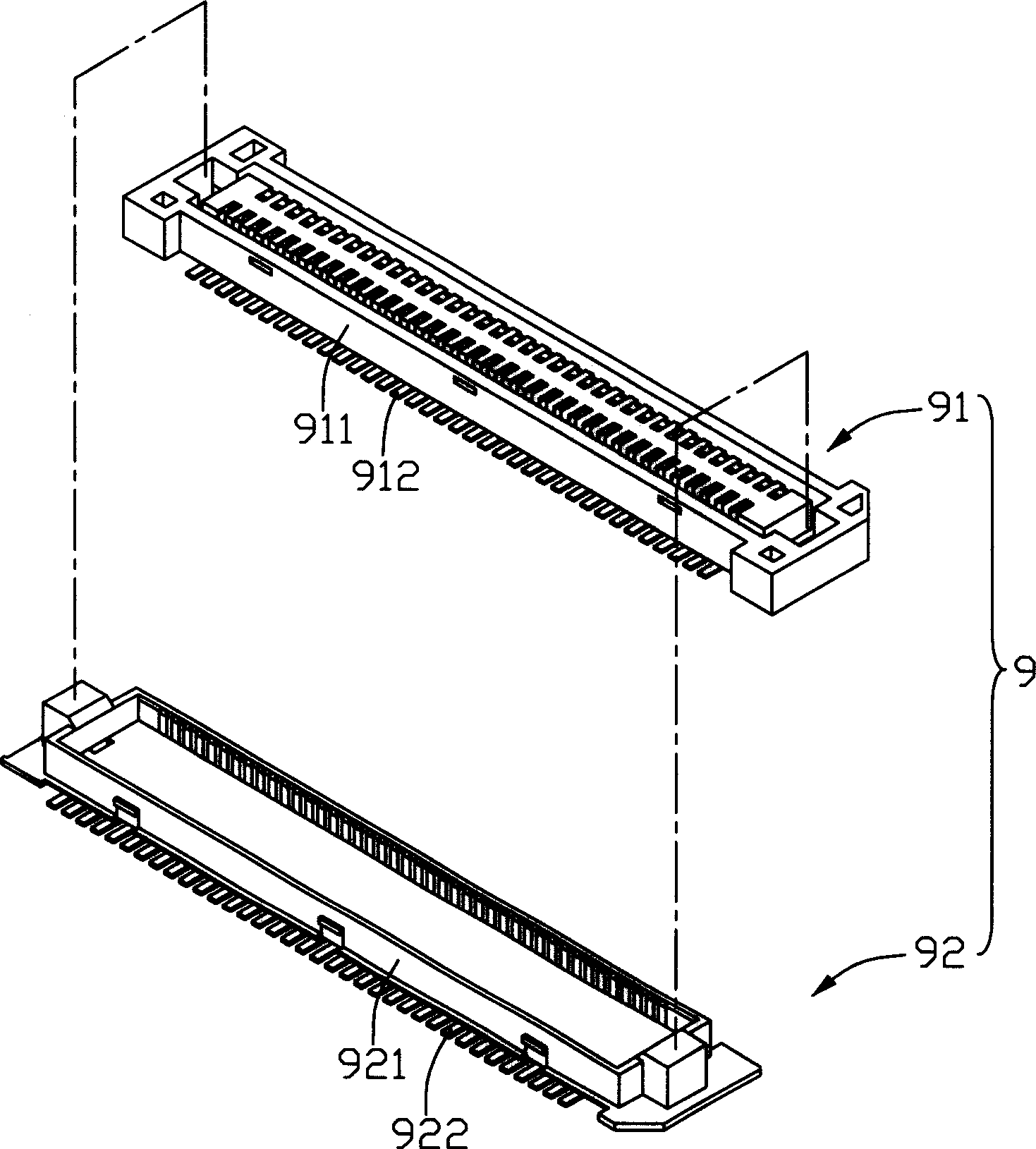

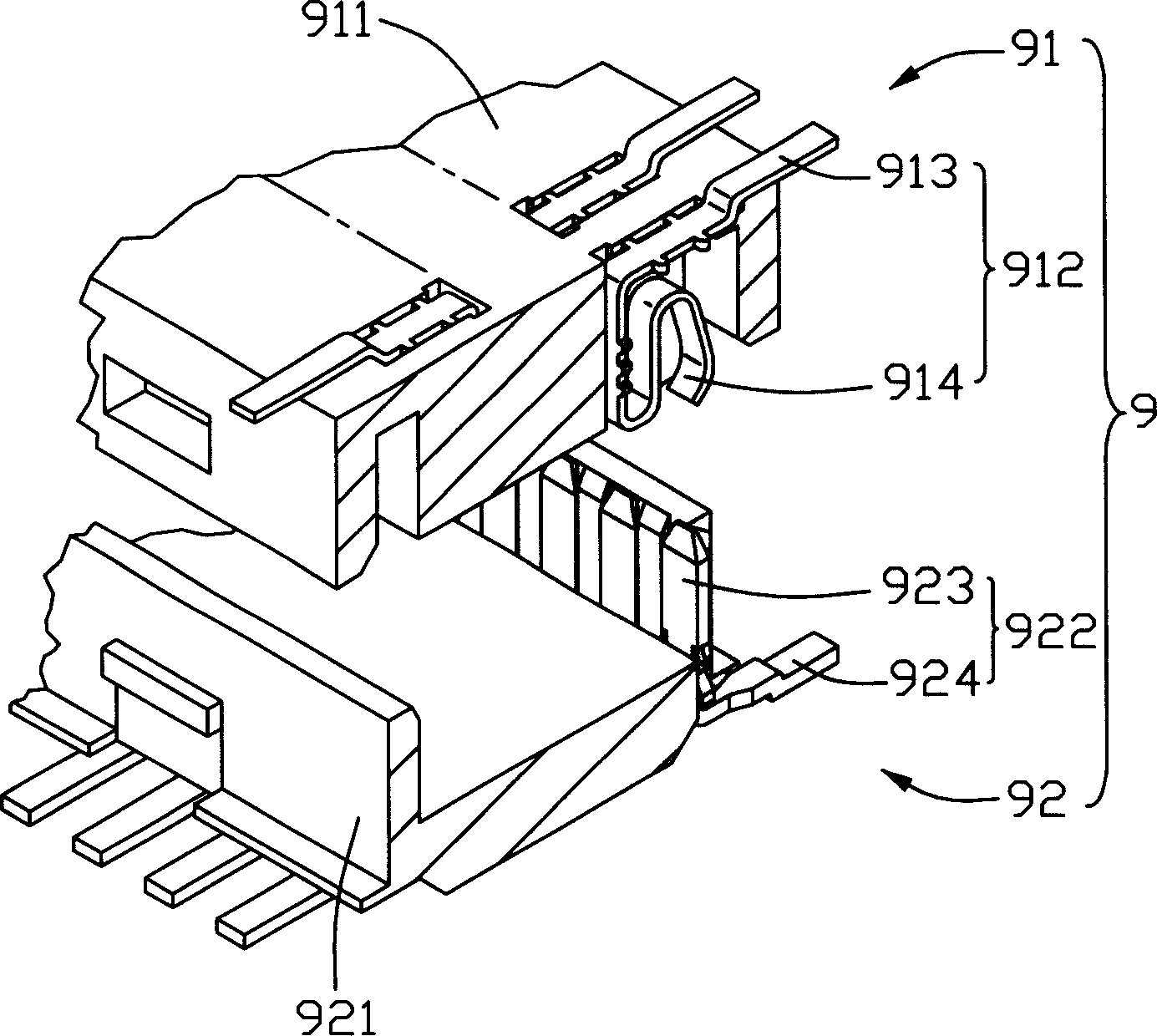

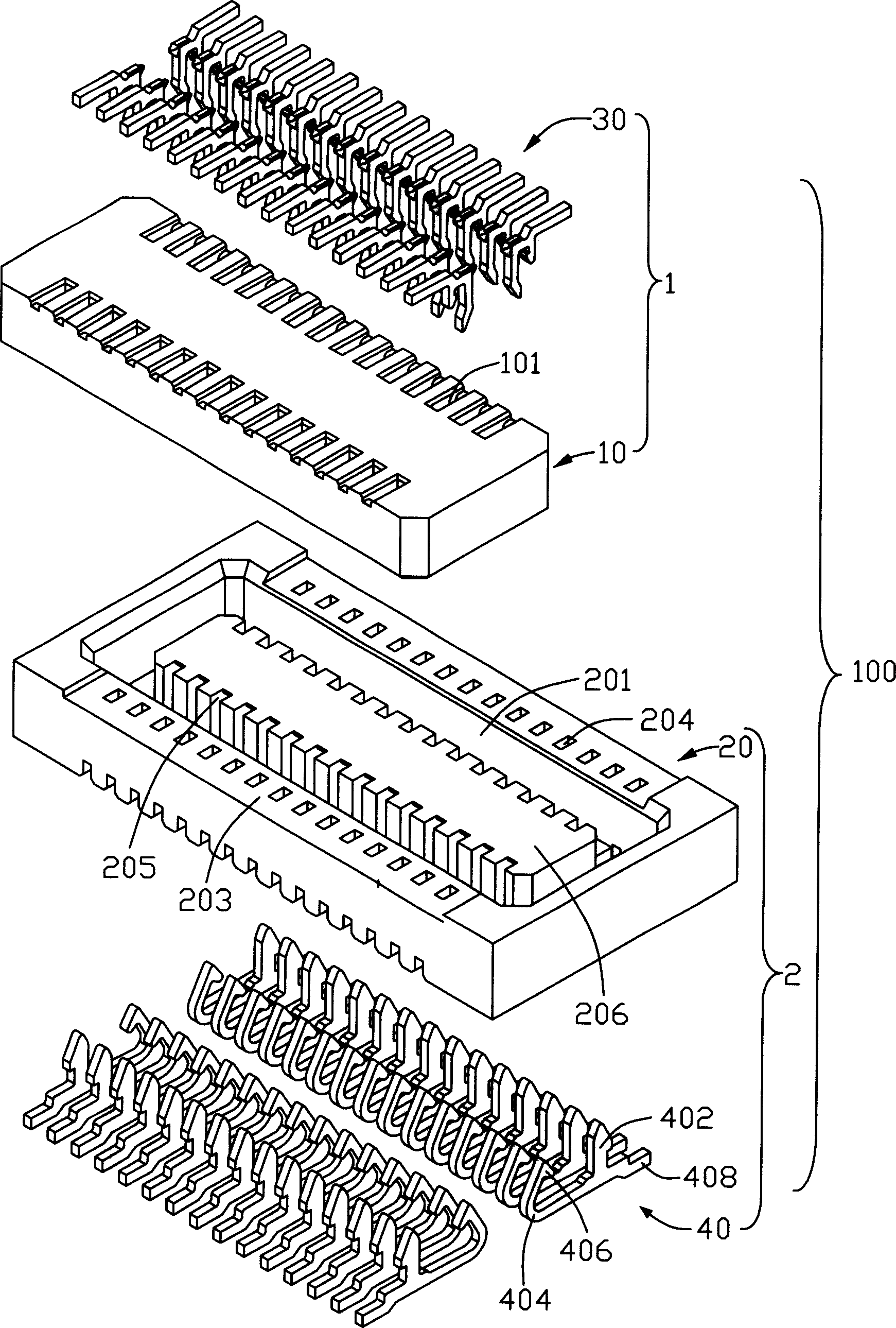

[0017] Please refer to image 3 As shown, the present invention provides a board-to-board connector 100 for electrically connecting two printed circuit boards (not shown), which is composed of a plug 1 and a socket 2, wherein the structures of the plug 1 and the socket 2 are both The shape is flat so as to have a smaller height and volume after docking, and it is also conducive to the firm welding of the plug 1 and the socket 2 on the printed circuit board.

[0018] Please refer to this Figure 4 , Figure 5 , Image 6 and Figure 7 The plug 1 includes a first insulating body 10 made of plastic and a plurality of first conductive terminals 30 accommodated in the first insulating body 10 . The first insulative housing 10 is generally rectangular in shape, and a rectangular first recess 102 is disposed in the center thereof, so that the first insulative housing 10 forms a bottom wall 103 and a pair of side walls 11 extending along the longitudinal direction. The two sidewal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com