Variable camber sliding bearing containing three oil wedges

A technology of sliding bearings and variable curvature, which is applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of limiting the scope of application, increasing investment, etc., achieve good automatic neutralization, reduce friction and wear, maintenance and replacement easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

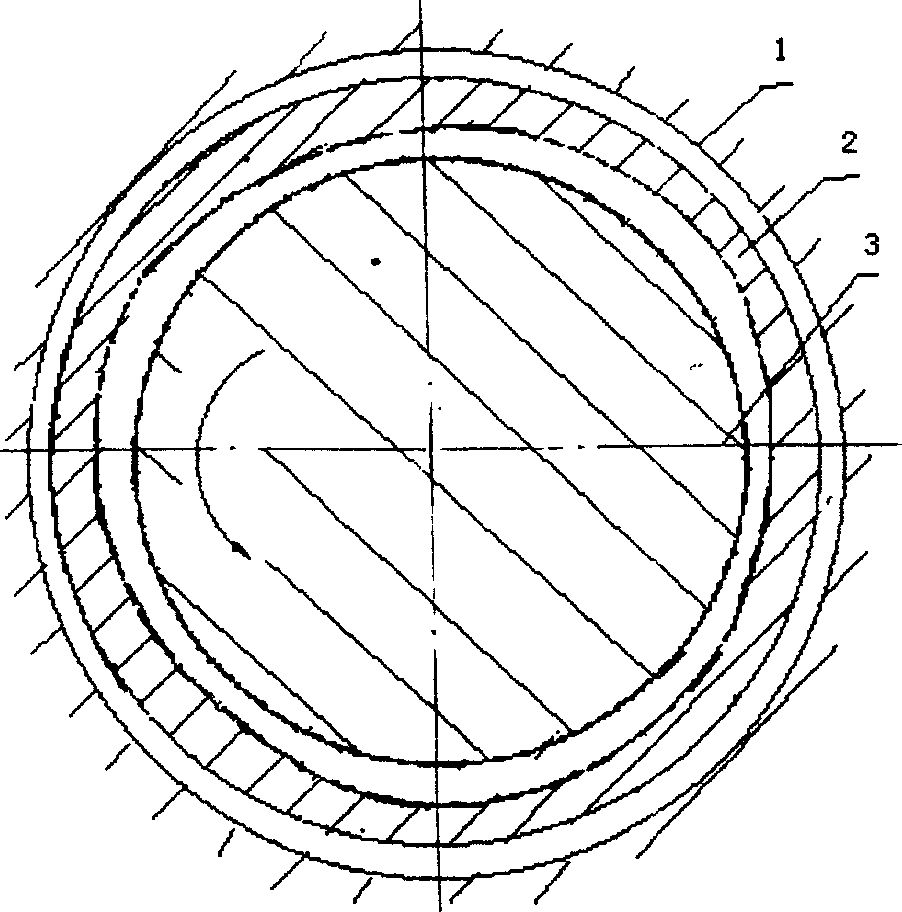

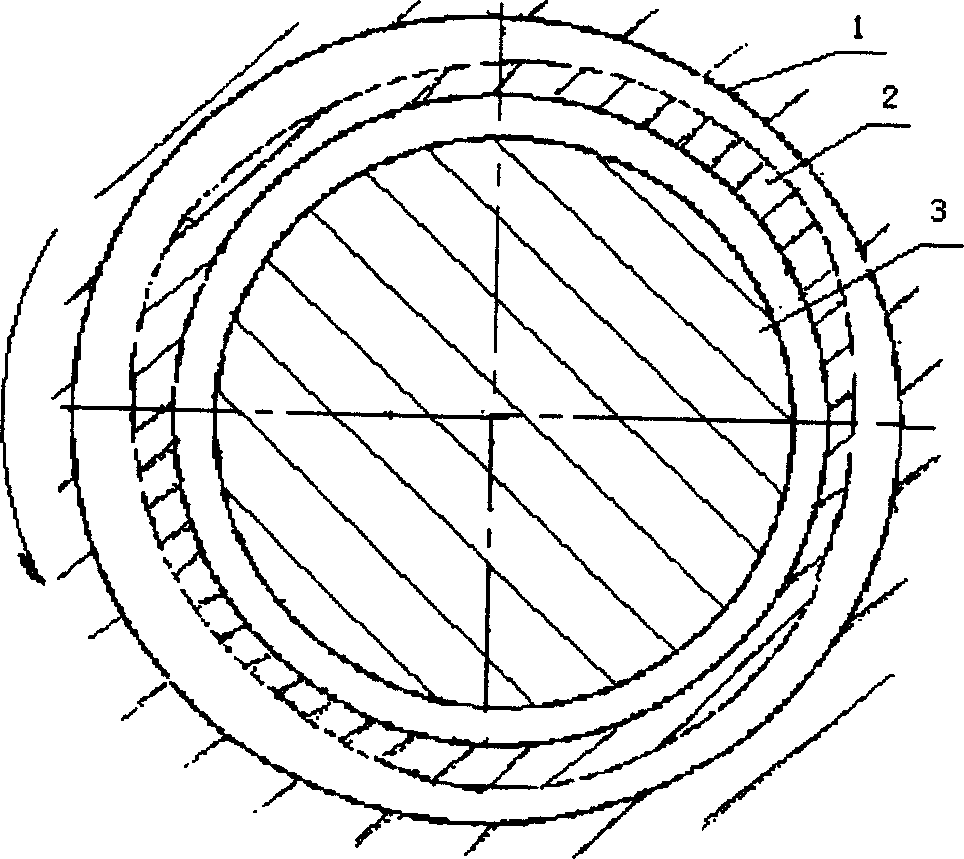

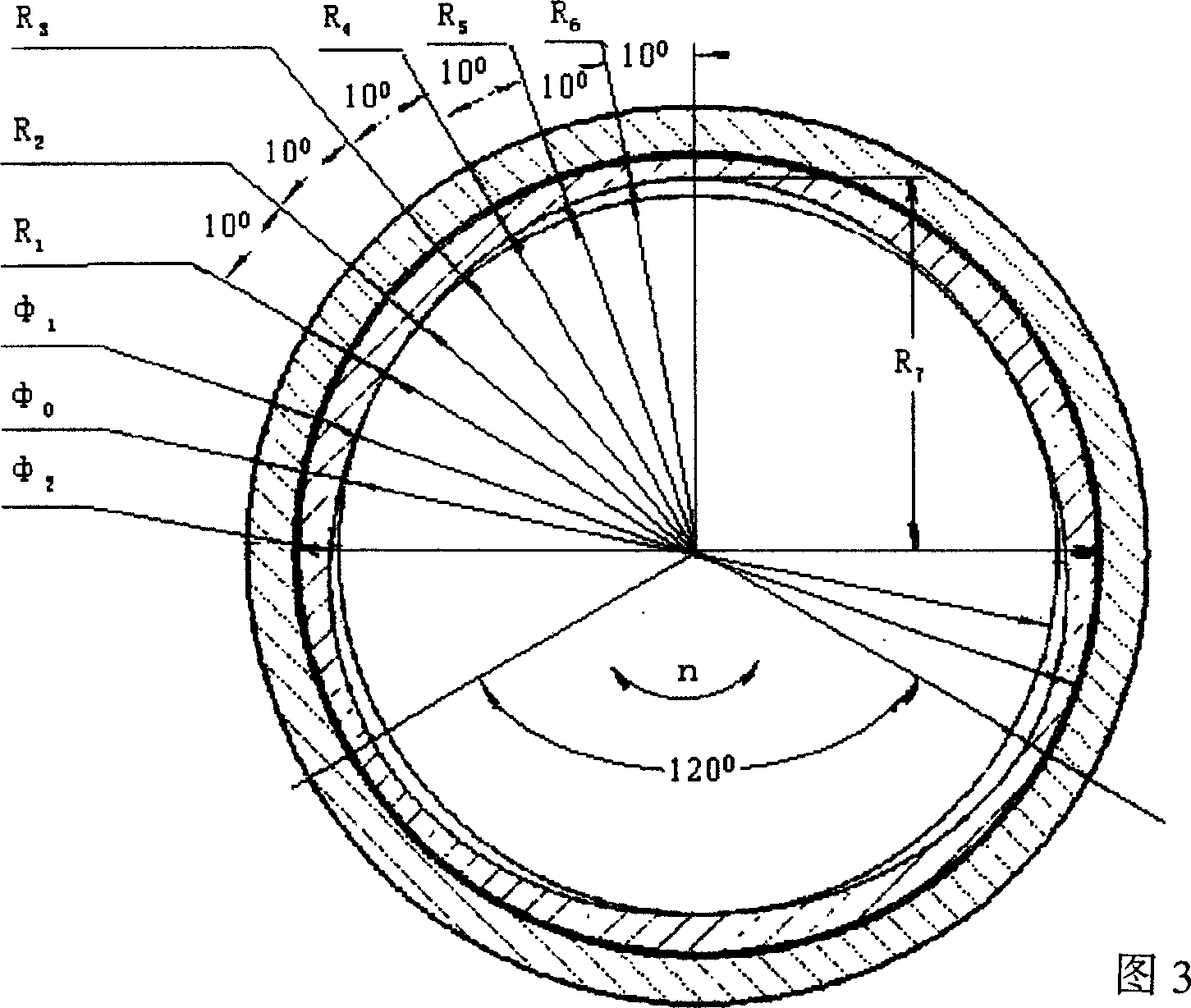

[0021] Figure 3 and Figure 4 show the structure and its specific examples when the rotating shaft needs to be forward and reverse. In Figure 3, φ 0 is the diameter of the shaft, φ 1 is the outer diameter of the bearing pad, φ 2 is the inner diameter of the bushing, R is the radius of curvature of the inner surface of the bearing bush, and the arrow of n indicates the direction of rotation of the shaft. Divide the bearing bush into three parts at 120°, and each part is 10° as a section. The radius of curvature R of the inner surface of the bearing bush is within the range of the first 60°. , each segment changes from the smallest to the largest in turn, and the gap between the shaft and the bearing bush also changes accordingly. The R value shown in Figure 3 and Figure 4 is the change of the first 60°, R 7 is the pad radius at maximum clearance, R 1 is the bearing pad radius at minimum clearance, from R 7 to R 1 , the R value gradually decreases, and the gap gradually dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com